Imikhiqizo

-

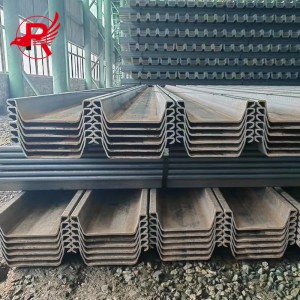

Ishidi Elinomumo Ophezulu Lekhwalithi Ephezulu SY295 400 × 100 Ishidi Lensimbi

Insimbiizindonga zenqwaba yeshidibaguqule imboni yezokwakha ngamandla abo angavamile, ukuzinza, kanye nokuguquguquka. Bayisisombululo esinamandla sokudala izakhiwo ezithembekile zokugcina umhlaba ezisekela ukumba, ukuvimbela ukuguguleka kwenhlabathi, kanye nokunikeza ukuzinza kumaphrojekthi ahlukahlukene obunjiniyela bezokwakha.

-

Inqwaba Yensimbi Egoqwe Kakhulu Yensimbi Eshisayo U Uhlobo lwe-SX10 SX18 SX27 Yokwakha

Ukufakwa kweshidi lensimbi eligoqiwe elishisayo lohlobo lwe-Uuhlobo lwenqwaba yeshidi lensimbi evame ukusetshenziswa kumaphrojekthi okwakha kanye nengqalasizinda. Lubunjwe njengo-U futhi lwenziwa ngamakhoyili ensimbi ashisayo. Lolu hlobo lokufakwa kweshidi lwaziwa ngamandla alo aphezulu nokuqina, okwenza lufanelekele ukusetshenziswa okudinga izindonga ezigcinayo, ama-bulkheads, kanye nezisekelo ukuze kumelwane nemithwalo ephezulu kanye nokucindezela. Lunikeza ukumelana okuhle kakhulu nokugqwala, okwenza lufanelekele nezimo zasolwandle. Ukufakwa kweshidi lensimbi elishisiwe elinohlobo lwe-U kuyatholakala ngobukhulu obuhlukahlukene, ubude, kanye namazinga ukuze kuhlangatshezwane nezidingo ezithile zephrojekthi.

-

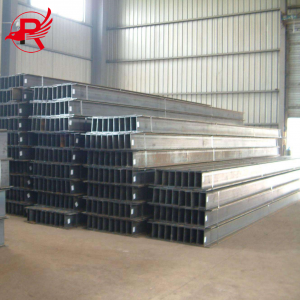

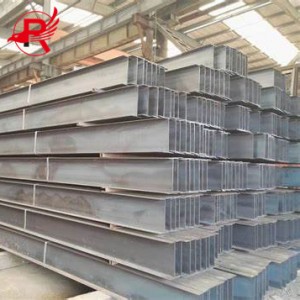

I-ASTM A572 S235jr Ibanga 50 150X150 W30X132 I-Wide Flange Ipe 270 Ipe 300 Heb 260 Hea 200 Ukwakhiwa kwe-H Beam

I-flange ebanziUmsebe ongu-Hiwugongolo lwensimbi oluyisakhiwo oluneflange ebanzi enikeza amandla nokuqina okwandisiwe. Ivame ukusetshenziswa kumaphrojekthi okwakha nobunjiniyela ukusekela imithwalo esindayo nokunikeza ukuzinza kwesakhiwo. Ukuma kwe-H kogongolo kuvumela ukuguquguquka okukhulu ekuklanyweni nasekusetshenzisweni kokwakhiwa.

-

Ishidi Lensimbi Eligoqiwe Elishisayo Uhlobo lwe-U S355GP

A Inqwaba yeshidi lensimbi elinomumo we-Uuhlobo lwensimbi olunesimo esiphambeneyo esifana nohlamvu "U". Luvame ukusetshenziswa kumaphrojekthi obunjiniyela bezokwakha kanye nokwakha ngezinhlelo ezahlukahlukene, njengezindonga zokugcina, ama-cofferdams, ukwesekwa kwesisekelo, kanye nezakhiwo zasemanzini.

Imininingwane yenqwaba yensimbi enomumo we-U ivame ukufaka imininingwane elandelayo:

Ubukhulu: Usayizi nobukhulu benqwaba yeshidi lensimbi, njengobude, ububanzi, kanye nobukhulu, kuchazwe ngokwezidingo zephrojekthi.

Izakhiwo ezihlukanisayo: Izakhiwo ezibalulekile zenqwaba yensimbi enomumo we-U zifaka phakathi indawo, umzuzu wokungahlali kahle, i-section modulus, kanye nesisindo ngobude beyunithi ngayinye. Lezi zakhiwo zibalulekile ekubaleni ukwakheka kwesakhiwo kanye nokuqina kwenqwaba.

-

Inqwaba Yeshidi Lensimbi Eligoqiwe Elishisayo le-Q235 Q355 U

Inqwaba yensimbi enomumo we-Uuhlobo lwensimbi olunesimo esiphambeneyo esifana nohlamvu "U". Luvame ukusetshenziswa kumaphrojekthi obunjiniyela bezokwakha kanye nokwakha ngezinhlelo ezahlukahlukene, njengezindonga zokugcina, ama-cofferdams, ukwesekwa kwesisekelo, kanye nezakhiwo zasemanzini.

Imininingwane yenqwaba yensimbi enomumo we-U ivame ukufaka imininingwane elandelayo:

Ubukhulu: Usayizi nobukhulu benqwaba yeshidi lensimbi, njengobude, ububanzi, kanye nobukhulu, kuchazwe ngokwezidingo zephrojekthi.

Izinzuzo Eziyinhloko:

1. Ukusebenza okuhle kakhulu kokumisa amanzi

2.Ukufakwa okulula futhi okusebenzayo

3. Ukuzivumelanisa nezimo okuphezulu

4.Ingasetshenziswa kabusha

5. Ezomnotho kanye nemvelo

6. Ukusetshenziswa kwesikhala okuphezulu

-

Inqwaba Yeshidi Lensimbi Esetshenzisiwe Enesimo Sokumisa Amanzi Esimayo Esishisayo Q235 Inqwaba Yeshidi Lensimbi Yekhabhoni Yohlobo lwe-U

Kumaphrojekthi okwakha esimanje, ukuzinza kwesakhiwo kanye nokusebenza kahle kwezindleko kubaluleke kakhulu. Isixazululo esisodwa esibhekana nazo zombili lezi zici ukuqaliswaizindonga zenqwaba yeshidi lensimbi.Lezi zakhiwo eziguquguqukayo nezihlala isikhathi eside zinikeza ukumelana okungavamile namandla aseceleni, okwenza zibe zilungele ukuvikela ekugugulekeni kwenhlabathi, ukungena kwamanzi, kanye nokungazinzi komhlabathi. Ngezinhlobo ezahlukene, njengezinqwaba zensimbi ezigoqiwe ezibandayo nezishisayo, kanye nokusetshenziswa kwensimbi ye-Q235, ukusetshenziswa kwezindonga zenqwaba yensimbi kubanzi.

-

Insimbi Ebunjwe Ngo-H Yesakhiwo Sensimbi Eshisayo Egoqwe Ngekhabhoni E-H

I-ASTM Insimbi Enomumo Ofana No-Hiyiphrofayili esebenza kahle kakhulu yesigaba esinqamulayo enokusatshalaliswa kwendawo enqamulayo okuthuthukisiwe kanye nesilinganiso samandla nesisindo esinengqondo. Iqanjwe ngoba isigaba sayo esinqamulayo sifana nohlamvu lwesiNgisi oluthi “H”. Njengoba zonke izingxenye ze-H-Beam zihlelwe ngama-engeli angakwesokudla, i-H-Beam inezinzuzo zokumelana nokugoba okunamandla kuzo zonke izinhlangothi, ukwakhiwa okulula, ukonga izindleko kanye nesisindo esincane sesakhiwo, futhi isetshenziswe kabanzi.

-

I-ASTM Steel Weld H Beam kanye nesakhiwo se-H Sezingxenye ze-Hot Rolled 300×300 Piles

I-ASTM Insimbi Enomumo Ofana No-H eyaziwa nangokuthi i-H-beam, uhlobo logongolo lwensimbi olunesigaba esiphambene ngesimo sohlamvu oluthi “H.” Izakhiwo zesigaba se-H zivame ukusetshenziswa ekwakheni nasebunjiniyelani ukuze zinikeze ukwesekwa kanye namakhono okuthwala imithwalo ezakhiweni, emabhulohweni, nakwezinye izakhiwo. Ukuma kwesakhiwo sesigaba se-H kuvumela ukusatshalaliswa okuphumelelayo kwesisindo futhi kunikeza amandla aphezulu nokuqina, okwenza kufaneleke ezinhlobonhlobo zezicelo zokwakha. Izakhiwo zesigaba se-H zivame ukwenziwa ngensimbi futhi zikhiqizwa ngezinqubo ezifana nokugoqa okushisayo noma ukushisela, okuholela ezintweni zokwakha ezihlala isikhathi eside neziguquguqukayo.

-

Insimbi Yesigaba Se-H | I-ASTM A36 H Beam 200 | Insimbi Yesakhiwo I-H Beam Q235b W10x22 100×100

Ugongolo lwe-ASTM A36 Huhlobo logongolo lwensimbi oluhambisana nencazelo ye-ASTM A36, echaza ukwakheka kwamakhemikhali, izakhiwo zemishini, kanye nezinye izidingo zensimbi yesakhiwo sekhabhoni. Lolu hlobo logongolo lwe-H luvame ukusetshenziswa ekwakheni nasekubunjeni kwesakhiwo ngenxa yamandla alo aphezulu, ukushibilika okuhle kakhulu, kanye nokusebenza kahle kwezindleko. Imishayo ye-ASTM A36 H isetshenziswa kabanzi kumaphrojekthi ahlukahlukene wokwakha nokwakha, inikeza ukwesekwa okubalulekile kanye namakhono okuthwala umthwalo. Izakhiwo zezinto ziyenza ifaneleke ezinhlotsheni eziningi zezicelo, futhi ivame ukusetshenziswa ekwakhiweni kwezakhiwo, amabhuloho, kanye nezinye izinhlaka zesakhiwo. Ngokusebenza kwayo okuthembekile kanye nokuguquguquka, i-ASTM A36 H Beam iyindlela ethandwayo yamaphrojekthi amaningi okwakha.

-

Abakhiqizi baseShayina be-Carbon Steel Hot Formed U Shaped Steel Sheet Pile yokwakha

Uhlobo lwenqwaba yeshidi Uibhekisela ohlotsheni lwenqwaba yeshidi lensimbi elibunjwe njengohlamvu "U." Lezi zinqwaba zeshidi zivame ukusetshenziswa ekwakheni ukudala izindonga zokugcina, ama-cofferdams, nezinye izakhiwo ezidinga ukugcinwa komhlaba noma amanzi. Isimo se-U sinikeza amandla nokuzinza, okwenza sifanelekele ukusetshenziswa okuhlukahlukene kumaphrojekthi obunjiniyela bezokwakha kanye nokwakha.

-

Inqwaba Yeshidi Lensimbi Yekhabhoni Eshisayo Egoqwe Ngohlobo lwe-ASTM A572 6mm 600X355X7mm Eyenziwe Ngohlobo lwe-U

Inqwaba yeshidi lensimbi yohlobo lwe-Uuhlobo lwezinto zensimbi ezisetshenziselwa ukugcina izindonga, ama-cofferdams, ama-bulkheads, nezinye izinhlelo zokusebenza ezidinga ukwesekwa noma ukugcinwa kwenhlabathi noma amanzi. Ibonakala nge-cross-section enomumo we-U futhi yenziwe ngensimbi enamandla aphezulu, enikeza ukuzinza okuhle kakhulu kwesakhiwo. Izinqwaba zensimbi zohlobo lwe-U zenzelwe ukuhlangana, zidala udonga oluqhubekayo lokugcinwa komhlaba okuphumelelayo nokusekelwa kokumba. Lezi zinto eziguquguqukayo nezihlala isikhathi eside zisetshenziswa kabanzi kumaphrojekthi obunjiniyela bezokwakha adinga izixazululo ezinokwethenjelwa nezisebenzayo zokugcina nokuqukatha izinhlobo ezahlukene zezinto.

-

I-ASTM H Steel Shaped H Beam | I-H-Beam Egoqekile Eshisayo Yamakholomu Nezingxenye Zensimbi

I-H-Beam Egoqekile Eshisayoiyisigxobo sesakhiwo esenziwe ngensimbi futhi sivame ukusetshenziswa kumaphrojekthi wokwakha nobunjiniyela besakhiwo. Sinesimo "se-H" esihlukile futhi sivame ukusetshenziselwa ukunikeza ukwesekwa kanye namakhono okuthwala umthwalo ezakhiweni nakwezinye izakhiwo. I-Hot Rolled H-Beam ikhiqizwa ngenqubo lapho insimbi ishiswa futhi idluliswa ngama-roller ukuze kufezwe ukuma nobukhulu obufunwayo. Amandla ayo nokuqina kwayo kwenza kube ukukhetha okuthandwayo kwezicelo eziningi zokwakha, okuhlanganisa amabhuloho, izakhiwo, kanye namaphrojekthi engqalasizinda.