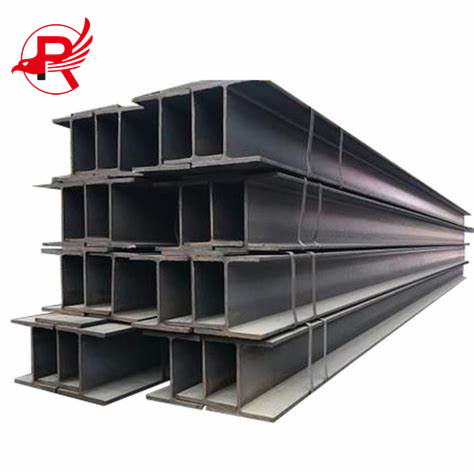

Insimbi Enomumo we-ASTM W4x13, W30x132, W14x82 | I-A36 Steel H Beam

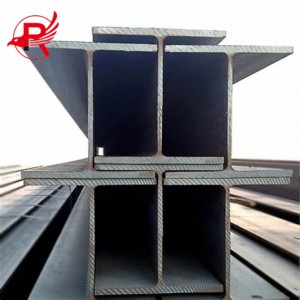

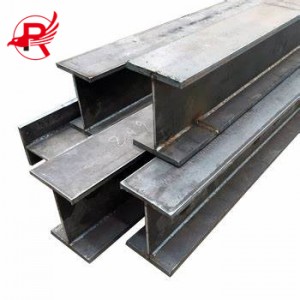

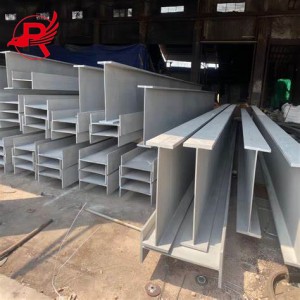

Imisebe Ebanzi Yeflange, eyaziwa nangokuthi i-I-beam noma i-H-beam, iwugongolo lwensimbi oluyisakhiwo olune-flange ebanzi, elinganiselayo kanye ne-web ehambisanayo. Lesi simo sivumela i-beam ukuthi isekele imithwalo esindayo futhi imelane namandla okugoba nokusonta. Imishayo ye-flange ebanzi ivame ukusetshenziswa ezakhiweni zokwakha, zezimboni, kanye nezindawo zokuhlala ukusekela izakhiwo zokwakha, amabhuloho, kanye nemishini emikhulu. Itholakala ngobukhulu obuhlukahlukene futhi ingenziwa ngezifiso ukuze ihlangabezane nezidingo ezithile zephrojekthi. Imishayo ye-flange ebanzi ikhiqizwa ngokwezindinganiso zemboni kanye nemininingwane ukuqinisekisa amandla aphezulu, ukuqina, kanye nokuzinza kumaphrojekthi ahlukahlukene okwakha kanye nengqalasizinda.

INQUBO YOKUKHIQIZWA KOMKHIQIZO

Ukulungiselela Kwasekuqaleni:

Ukuncibilikisa:

I-Billet Yokuphonsa Eqhubekayo:

Ukujikijela Okushisayo:

Qedela Ukugoqa:

Ukupholisa:

Ukuhlolwa Kwekhwalithi Nokupakisha:

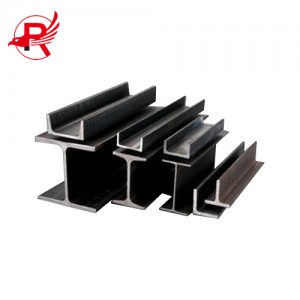

USAYIZI WOMKHIQIZO

INZUZO

I-Flange Ebanzi, zisetshenziswa ezinhlotsheni ezahlukene zesakhiwo ukusekela imithwalo esindayo ngezikhathi ezinde. Idizayini yeflange ebanzi inikeza amandla amahle kakhulu okuthwala umthwalo kanye nokumelana nokugoba nokusonta.imisebe engu-Wzitholakala ngobukhulu obuhlukahlukene futhi zivame ukusetshenziswa ekwakheni, ezitshalweni zezimboni, emabhulohweni, kanye nakumaphrojekthi engqalasizinda. Ukwakheka kwazo kuhambisana nezindinganiso zemboni kanye nemininingwane ukuqinisekisa ubuqotho besakhiwo nokuphepha. Izici ezivamile zifaka phakathi amandla aphezulu, ukuguquguquka, kanye nekhono lokwenza ngokwezifiso kalula ngokwezidingo ezithile zephrojekthi.

IPHROJEKTHI

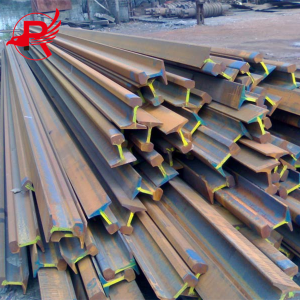

Inkampani yethu ineminyaka eminingi yesipiliyoni ekuhwebeni kwamanye amazweUmsebe we-W4x13. Inani eliphelele lemisebe ye-H ethunyelwe eCanada kulokhu lingaphezu kwamathani ayizigidi ezingu-8. Ikhasimende lizohlola izimpahla ezisefektri. Uma izimpahla seziphumelele ukuhlolwa, kuzokhokhwa futhi kuthunyelwe. Selokhu kwaqala ukwakhiwa kwalo msebenzi, inkampani yethu ihlele ngokucophelela uhlelo lokukhiqiza futhi yahlanganisa ukugeleza kwenqubo ukuqinisekisa ukulethwa ngesikhathi kwephrojekthi yensimbi enomfanekiso we-H. Njengoba isetshenziswa ezakhiweni ezinkulu zefektri, izidingo zokusebenza kwemikhiqizo yensimbi enomfanekiso we-H ziphakeme kunokumelana nokugqwala kwensimbi enomfanekiso we-H yesikhulumi samafutha. Ngakho-ke, inkampani yethu iqala emthonjeni wokukhiqiza futhi yandisa ukulawulwa kokwenziwa kwensimbi, ukuphonswa okuqhubekayo kanye nezinqubo ezihlobene nokugoqa. Qinisa ikhwalithi yemikhiqizo yemininingwane eyahlukahlukene ukuze ilawulwe ngempumelelo kuzo zonke izici, iqinisekise izinga lokudlula elingu-100% lemikhiqizo eqediwe. Ekugcineni, ikhwalithi yokucubungula yensimbi enomfanekiso we-H yaqashelwa ngamakhasimende ngazwi linye, futhi ukubambisana kwesikhathi eside kanye nezinzuzo zombili kwafezwa ngesisekelo sokwethembana.

UKUHLOLWA KOMKHIQIZO

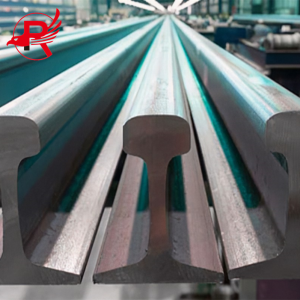

OkuvamileUmsebe we-W30x132nomaI-H-Beam S275jr, uma okuqukethwe kwekhabhoni kungu-0.4% kuya ku-0.7%, futhi izidingo zempahla yemishini zingephezulu kakhulu, ukujwayela kungasetshenziswa njengokwelashwa kokushisa kokugcina. Okokuqala, amakholomu ensimbi anomumo ophambanayo kudingeka akhiqizwe. Ngemva kokuhlukaniswa komsebenzi efektri, abese ehlanganiswa, elinganiswa, futhi ehlolwa ukuqinisekisa ukuthi imikhiqizo iyafaneleka bese ethuthwa endaweni yokwakha ukuze ihlanganiswe. Ngesikhathi senqubo yokuhlanganisa, ukufaka kufanele kwenziwe ngokuhambisana nezinqubo ezifanele. , Ngale ndlela kuphela lapho ikhwalithi yomkhiqizo ingaqinisekiswa ngempumelelo. Ngemva kokuba ukuhlanganiswa sekuqediwe, imiphumela yokugcina yokufaka kumele ihlolwe. Ngemva kokuhlolwa, amagagasi e-ultrasonic kumele asetshenziswe ukwenza ukuhlolwa okungonakalisi kwangaphakathi, ukuze amaphutha abangelwe ngesikhathi sokuhlanganiswa asuswe ngempumelelo. Ngaphezu kwalokho, ukucubungula izinsika eziphambanayo nakho kuyadingeka. Ngesikhathi sokufakwa kwesakhiwo sensimbi, okokuqala udinga ukukhetha isichasiselo esijwayelekile, uvale inethi yokulawula, bese wenza isilinganiso esiqondile sokuphakama okuphezulu kwekholomu. Ngemva kwalokho, ukufuduka kwengxenye ephezulu yekholomu kanye nesakhiwo sensimbi kudinga ukucutshungulwa ukuze kuguqulwe kakhulu, bese imiphumela ephansi kakhulu kanye nemiphumela yokuhlola yekholomu engezansi kucutshungulwa ngokuphelele. Ukucutshungulwa kwezinyawo ezijiyile kudinga ukwenziwa ngemva kokuba indawo yekholomu yensimbi inqunyiwe. Ngokuhlaziya idatha yokucubungula, ukuma kwekholomu yensimbi kulungiswa futhi. Ngemva kokuba ukufakwa sekuqediwe, amarekhodi okulinganisa adinga ukubuyekezwa kanye nezinkinga zokushisela zidinga ukuhlolwa. Ngaphezu kwalokho, ukuvalwa kwamaphoyinti okulawula kudinga ukuhlolwa futhi. Okokugcina, umdwebo wedatha yokulawula yangaphambi kokulawula yekholomu yensimbi engezansi kudinga ukudweba.

ISICELO

I-flange ebanziimishayozinezinhlobo eziningi zezicelo kwezokwakha kanye nobunjiniyela bezakhiwo. Ezinye zezindlela ezisetshenziswa kakhulu zifaka:

Ukwakhiwa kwesakhiwo: Imishayo emikhulu ye-flange isetshenziswa njengamalungu ayinhloko okuthwala imithwalo ekwakhiweni kwezakhiwo, okunikeza ukwesekwa kwezitezi, uphahla, kanye nokuqina kwesakhiwo sonke.

Amabhuloho: Imishayo emikhulu ye-flange ivame ukusetshenziswa ekwakhiweni kwezakhiwo zamabhuloho, okunikeza ukwesekwa kwemigwaqo, izindlela zokuhamba ngezinyawo, kanye nemizila yesitimela.

Izakhiwo zezimboni: Lezi zingodo zivame ukusetshenziswa ekwakhiweni kwezindawo zezimboni, njengezindawo zokugcina impahla, izitshalo zokukhiqiza, nezikhungo zokusabalalisa, ukusekela imishini esindayo nemishini.

Amaphrojekthi engqalasizinda: Imishayo emikhulu ye-flange ibalulekile ekwakhiweni kwamaphrojekthi engqalasizinda njengemigudu, izikhumulo zezindiza, kanye nezinkundla zemidlalo, okunikeza ukwesekwa kwesakhiwo sezindawo ezinkulu kanye nemithwalo esindayo.

Izakhiwo zokusekela: Imishayo ye-flange ebanzi isetshenziswa njengezinsika zokusekela kanye nemishayo ezisetshenziswayo ezahlukene zesakhiwo, okunikeza amandla nokuqina kwesakhiwo sonke.

Sekukonke, imishayo ye-flange ebanzi iyizakhi zesakhiwo eziguquguqukayo ezisetshenziswa kumaphrojekthi ahlukahlukene okwakha lapho amandla, ukuzinza, kanye nomthamo wokuthwala imithwalo kubalulekile.

UKUPHAKISHA NOKUTHUMELA

Ukupakisha:

Izinqwaba Zamashidi Ezinqwabelana Ngokuqinile: Insimbi ye-stack-section H ihlelekile futhi izinzile, iqinisekisa ukuthi ihlelwe kahle ukuze kuvinjelwe ukungazinzi. Sebenzisa amabhande okubopha noma okupakisha ukuze uqinise izinqwaba futhi ugweme ukugudluzwa ngesikhathi sokuthuthwa.

Ukusebenzisa Izinto Zokupakisha Ezivikelayo: Songa izinqwaba zamashidi ahlanganisiwe ngezinto ezingangenisi umswakama njengepulasitiki noma iphepha elingangeni manzi ukuze uzivikele emanzini, umswakama nezinye izinto zemvelo. Lokhu kusiza ukuvimbela ukugqwala nokugqwala.

Ezokuthutha:

Ukukhetha Izindlela Zokuthutha Ezifanele: Ngokusekelwe enanini kanye nesisindo sezinqwaba zamashidi, khetha izindlela zokuthutha ezifanele njengezimoto ezifulethi, izitsha noma imikhumbi. Cabangela izici ezifana nebanga, isikhathi, izindleko kanye nanoma yiziphi izidingo zomthetho zokuhamba.

Ukusebenzisa Imishini Yokuphakamisa Efanelekile: Sebenzisa imishini yokuphakamisa efanele njengamakhreyini, ama-forklift noma ama-loader ukulayisha nokukhipha izinqwaba zensimbi zohlobo lwe-U. Qinisekisa ukuthi imishini esetshenzisiwe inomthamo owanele wokuthwala umthwalo wokuphakamisa ngokuphephile isisindo sezinqwaba zeshidi.

Ukuvikela Izimpahla: Sebenzisa izintambo, izisekelo noma ezinye izindlela ezifanele ukuze uqinise izinqwaba zeshidi ezipakishiwe ezimotweni zokuthutha, ukuvimbela ukushelela, ukushelela noma ukuwa ngesikhathi sokuthuthwa.

AMANDLA ENKAMPANI

Kwenziwe eShayina, isevisi yekilasi eliphezulu, ikhwalithi ephezulu, idumile emhlabeni jikelele

1. Umphumela Wesilinganiso: Inkampani yethu inochungechunge olukhulu lokuhlinzeka kanye nefektri enkulu yensimbi, efinyelela imiphumela emikhulu kwezokuthutha kanye nokuthengwa kwempahla, futhi iba yinkampani yensimbi ehlanganisa ukukhiqiza kanye nezinsizakalo.

2. Ukwehlukahluka komkhiqizo: Ukwehlukahluka komkhiqizo, noma iyiphi insimbi oyifunayo ingathengwa kithi, ikakhulukazi ehilelekile ezakhiweni zensimbi, izinsimbi zensimbi, izinqwaba zeshidi lensimbi, amabhulakhethi e-photovoltaic, insimbi yesiteshi, amakhoyili ensimbi ye-silicon neminye imikhiqizo, okwenza kube lula ukukhetha uhlobo lomkhiqizo olufunayo ukuze luhlangabezane nezidingo ezahlukene.

3. Ukunikezwa okuzinzile: Ukuba nomugqa wokukhiqiza ozinzile kanye nochungechunge lokunikezwa kunganikeza ukunikezwa okuthembekile. Lokhu kubaluleke kakhulu kubathengi abadinga insimbi eningi.

4. Ithonya lomkhiqizo: Linethonya lomkhiqizo eliphezulu kanye nemakethe enkulu

5. Isevisi: Inkampani enkulu yensimbi ehlanganisa ukwenza ngokwezifiso, ezokuthutha kanye nokukhiqiza

6. Ukuncintisana kwentengo: intengo enengqondo

*Thumela i-imeyili ku-[i-imeyili ivikelwe]ukuthola ikhotheshini yamaphrojekthi akho