Umkhiqizi we-steel h-beams ASTM A572 Grade 50 W14X82 W30X120 W150x150 Standard Viga H Beam I Beamcarbon vigas de acero Channel Steel Osayizi

Unyawo oluncane, olulungele ukwakhiwa kwesimo sezulu sonke, oluthintwa kancane yizimo zezulu... Isivinini sokwakha Isivinini sokugoqwa okushisayoI-Beam H ukukhiqizwa kwesakhiwo sikakhonkolo wokwakha cishe izikhathi ezingu-2-3, izinga lokushintshaniswa kwenhloko-dolobha liphindwe kabili, futhi izindleko zezezimali ziyancipha, ngaleyo ndlela kulondoloza ukutshalwa kwezimali.

INQUBO YOKUKHIQISWA KOMKHIQIZO

1. Ukulungiselela Okokuqala: Lokhu kuhlanganisa ukuthengwa kwezinto ezingavuthiwe, ukuhlolwa kwekhwalithi, nokulungiswa kwezinto. Izinto zokusetshenziswa ngokuvamile ziyinsimbi eshisayo ekhiqizwa ezithandweni zekhwalithi ephezulu noma ezithandweni zikagesi, futhi zifakwa ekukhiqizeni ngemva kokuhlolwa kwekhwalithi.

2. Ukuncibilika: Insimbi eshisayo ithululelwa kusiguquli futhi inani elifanele le-regrind noma i-iron yengulube yengezwa enqubweni yokwenza insimbi. Phakathi nenqubo yokwenza insimbi, okuqukethwe kwekhabhoni kanye nezinga lokushisa lensimbi encibilikisiwe kulawulwa ngokulungisa inani le-ejenti ye-graphitizing kanye nenani le-oxygen elivuthela esithandweni.

3. Ukusakaza Okuqhubekayo: Ama-slabs ensimbi athululelwa emshinini wokuphonsa oqhubekayo, lapho amanzi agelezayo efafazwa khona esikhunjeni, kancane kancane eqinisa insimbi encibilikisiwe ku-slab.

4. I-Hot Rolling: Ama-slabs ashiswa kumshini wokugaya oshisayo ukuze afinyelele ubukhulu obucacisiwe kanye nejometri.

5. Ukuqeda Ukugoqa: Ama-slabs ashisayo agqitshiwe. Ngokulungisa amapharamitha wokugaya nokulawula amandla aginqikayo, ubukhulu nokwakheka kwe-slab kuthuthukiswa nakakhulu.

6. Ukupholisa: Insimbi eqediwe iyapholiswa ukuze kuncishiswe izinga lokushisa futhi kunzinze ubukhulu bayo nezakhiwo zayo.

7. Ukuhlolwa kwekhwalithi nokupakishwa: Imikhiqizo eqediwe ihlolwe ikhwalithi futhi ihlanganiswe ngokuvumelana nosayizi kanye nezidingo zobuningi.

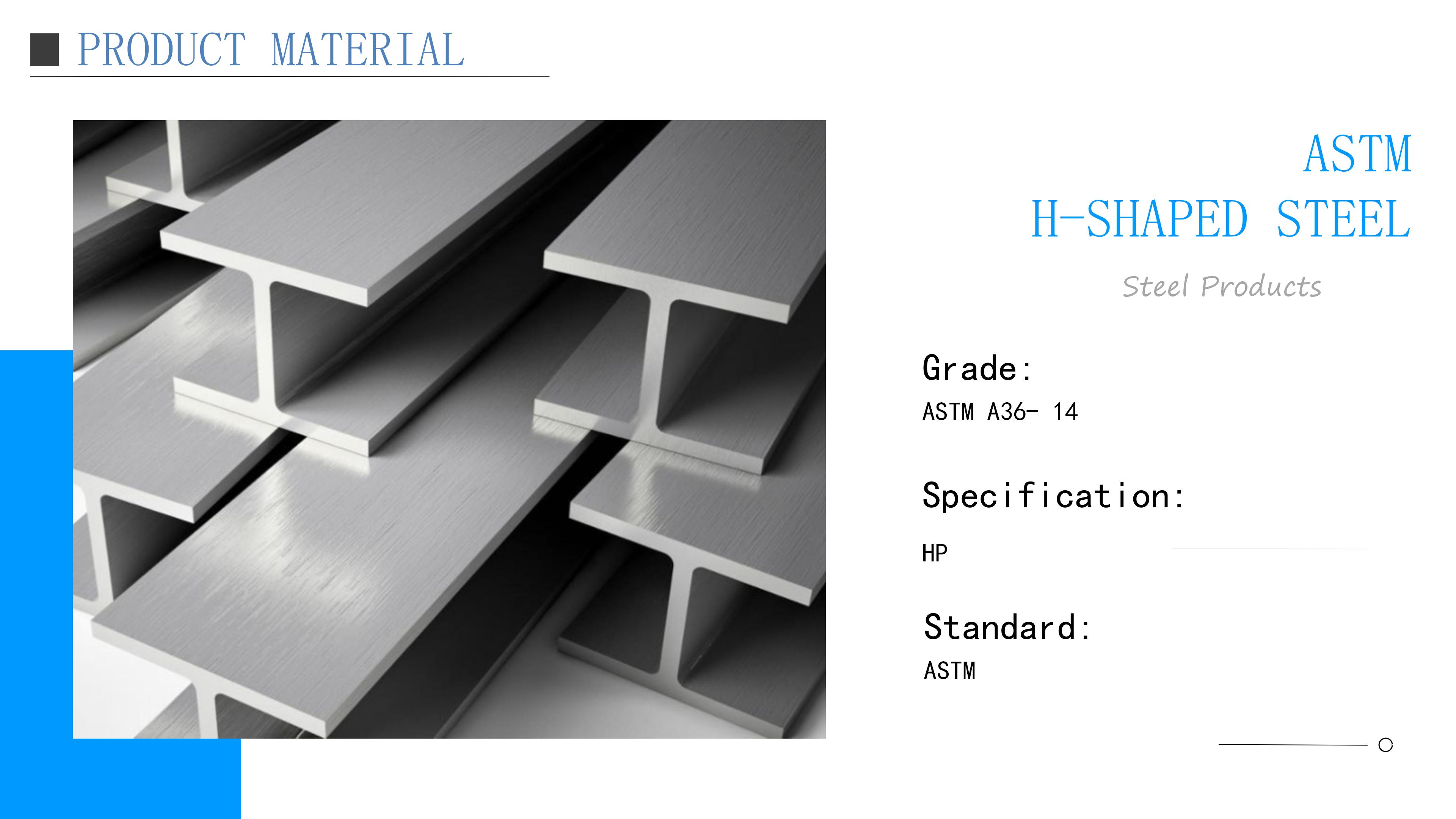

USIZI WOMTHETHO

| IMICIMBI YEI-H-BEAM | |

| 1. Usayizi | 1) Ukuqinas:5-34 mmnoma ngokwezifiso |

| 2)Ubude:6-12m | |

| 3)Ukuqina Kwewebhu:6mm-16mm | |

| 2. Okujwayelekile: | I-JIS ASTM DIN EN GB |

| 3.Impahla | Q195 Q235 Q345 A36 S235JR S335JR |

| 4. Indawo yefekthri yethu | I-Tianjin, China |

| 5. Ukusetshenziswa: | 1)isakhiwo esisezingeni eliphezulu sezimboni |

| 2)Izakhiwo Ezindaweni Ezijwayele Ukuzamazama | |

| 3)amabhuloho amakhulu anama-span amade | |

| 6. Ukugqoka: | 1) Igcwele 2) Upende Omnyama (i-varnish) 3) amagalani |

| 7. Isu: | hot rolling |

| 8. Uhlobo: | Inqwaba yeshidi lohlobo lwe-H |

| 9. Isimo Sesigaba: | H |

| 10. Ukuhlola: | Ukuhlolwa kwekhasimende noma ukuhlolwa ngumuntu wangaphandle. |

| 11. Ukulethwa: | Isitsha, Umkhumbi Wenqwaba. |

| 12. Mayelana Nekhwalithi Yethu: | I-1) Akukho monakalo, akukho okugobile 2) Mahhala for oiled & marking I-3) Zonke izimpahla zingahlolwa ngokuhlolwa komuntu wesithathu ngaphambi kokuthunyelwa |

| Divis ibn (ukujula x id | Iyunithi Isisindo kg/m) | Sandard Sectional Ubukhulu (mm) | Okwesikhashana Indawo cm² | ||||

| W | H | B | 1 | 2 | r | A | |

| HP8x8 | 53.5 | 203.7 | 207.1 | 11.3 | 11.3 | 10.2 | 68.16 |

| HP10x10 | 62.6 | 246.4 | 255.9 | 10.5 | 10.7 | t2.7 | 70.77 |

| 85.3 | 253.7 | 259.7 | 14.4 | 14.4 | 127 | 108.6 | |

| HP12x12 | 78.3 | 2992 | 305.9 | 11.0 | 11.0 | 15.2 | 99.77 |

| 93.4 | 303.3 | 308.0 | 13.1 | 13.1 | 15.2 | 119.0 | |

| 111 | 308.1 | 310.3 | 15.4 | 15.5 | 15.2 | 140.8 | |

| 125 | 311.9 | 312.3 | 17.4 | 17.4 | 15.2 | 158.9 | |

| HP14x14% | 108.0 | 345.7 | 370.5 | 12.8 | t2.8 | 15.2 | 137.8 |

| 132.0 | 351.3 | 373.3 | 15.6 | 15.6 | 15.2 | 168.4 | |

| 152.0 | 355.9 | 375.5 | 17.9 | 17.9 | 15.2 | 193.7 | |

| 174.0 | 360.9 | 378.1 | 20.4 | 20.4 | 15.2 | 221.5 | |

I-ADVANTAGE

I-flange ye H Beam 100x100iyahambisana noma icishe ihambisane ngaphakathi nangaphandle, futhi isiphetho se-flange sikwi-Engeli engakwesokudla, ngakho-ke ibizwa ngokuthi i-parallel flange I-steel. Ugqinsi lwewebhu yensimbi emise okwe-H incane kunaleyo ye-I-imishayo evamile enobude obufanayo bewebhu, futhi ububanzi be-flange bukhulu kunobu-I-imishayo evamile enobude obufanayo bewebhu, ngakho-ke ibizwa nangokuthi i-wide-rim I-imishayo. Kunqunywa ukuma, i-modulus yesigaba, umzuzu we-inertia namandla ahambisanayo we-H-beam ngokusobala kungcono kunaleyo ye-I-beam evamile enesisindo esisodwa esisodwa.

PROJECT

Inkampani yethu inesipiliyoni seminyaka eminingi ekuhwebeni kwamanye amazweH Beam 200x200. Isamba senani le-H-beams elithunyelwa eCanada ngalesi sikhathi lingaphezu kwamathani ayi-8,000,000. Ikhasimende lizohlola izimpahla efekthri. Lapho izimpahla sezidlulile ekuhlolweni, inkokhelo izokwenziwa futhi ithunyelwe. Kusukela kwaqala ukwakhiwa kwale phrojekthi, inkampani yethu ihlele ngokucophelela uhlelo lokukhiqiza futhi yahlanganisa ukugeleza kwenqubo ukuze kuqinisekiswe ukulethwa okufika ngesikhathi kwephrojekthi yensimbi emise okwe-H. Njengoba isetshenziswa ezakhiweni ezinkulu zefektri, izidingo zokusebenza zemikhiqizo yensimbi emise okwe-H ziphakeme kunokumelana nokugqwala kwesiteji samafutha sensimbi emise okwe-H. Ngakho-ke, inkampani yethu iqala emthonjeni wokukhiqiza futhi ikhulisa ukulawulwa kokwenziwa kwensimbi, ukusakaza okuqhubekayo kanye nezinqubo ezihlobene nokugingqika. Qinisa ikhwalithi yemikhiqizo yokucaciswa okuhlukahlukene ukuze ilawulwe ngempumelelo kuzo zonke izici, uqinisekise izinga lokuphasa elingu-100% lemikhiqizo eqediwe. Ekugcineni, ikhwalithi yokucubungula yensimbi emise okwe-H yaqashelwa ngazwi linye ngamakhasimende, futhi ukubambisana kwesikhathi eside kanye nokuhlomula okuhlangene kwafinyelelwa ngesisekelo sokwethembana.

UKUHLOLWA KOMKHIQIZO

Izidingo zeH Beam Inqwabaukuhlola ikakhulukazi kubandakanya izici ezilandelayo:

Ikhwalithi yokubukeka: Ikhwalithi yokubukeka yensimbi emise okwe-H kufanele ihambisane nezindinganiso ezifanele kanye nezidingo zoku-oda. Ubuso kufanele busheleleke futhi bube bushelelezi, bungabi namazinyo asobala, imihuzuko, ukugqwala nokunye ukukhubazeka.

Ubukhulu beJiyomethri: Ubude, ububanzi, ubude, ukujiya kwewebhu, ukujiya kwe-flange nobunye ubukhulu bensimbi emise okwe-H kufanele kuhambisane nezindinganiso ezifanele kanye nezidingo zoku-oda.

Ijika: I-curvature yensimbi emise okwe-H kufanele ihambisane nezindinganiso ezifanele kanye nezidingo zoku-oda. Ingatholwa ngokulinganisa ukuthi izindiza ezikuzo zombili iziphetho zensimbi emise okwe-H ziyahambisana noma zisebenzisa imitha egobayo.

Phendula: I-twist yensimbi emise okwe-H kufanele ihambisane nezindinganiso ezifanele kanye nezidingo zoku-oda. Ingatholwa ngokulinganisa ukuthi uhlangothi lwensimbi emise okwe-H luqondile noma lunemitha yokusonta.

Ukuchezuka kwesisindo: Isisindo sensimbi emise okwe-H kufanele sihambisane nezindinganiso ezifanele kanye nezidingo zoku-oda. Ukuchezuka kwesisindo kungatholwa ngokukala.

Ukwakheka kwamakhemikhali: Uma insimbi emise okwe-H idinga ukushiselwa noma icutshungulwe ngenye indlela, ukwakheka kwayo kwamakhemikhali kufanele kuhambisane nezindinganiso ezifanele kanye nezidingo zoku-oda.

Izakhiwo zemishini: Izakhiwo zemishini yensimbi emise okwe-H kufanele ihambisane nezindinganiso ezifanele kanye nezidingo zoku-oda, okuhlanganisa amandla aqinile, iphuzu lesivuno, ubude nezinye izinkomba.

Ukuhlola okungabhubhisi: Uma insimbi emise okwe-H idinga ukuhlolwa okungabhubhisi, kufanele ihlolwe ngokuhambisana nezindinganiso ezifanele kanye nezidingo zoku-oda ukuze kuqinisekiswe ukuthi ikhwalithi yayo yangaphakathi yinhle.

Ukupakisha nokumaka: Ukupakishwa nokumaka kwensimbi emise okwe-H kufanele kuhambisane nezindinganiso ezifanele kanye nezidingo zoku-oda ukuze kube lula ukuthuthwa nokugcinwa.

Ngamafuphi, izidingo ezingenhla kufanele zicatshangelwe ngokugcwele lapho kuhlolwa insimbi emise okwe-H ukuze kuqinisekiswe ukuthi ikhwalithi yayo ihlangabezana nezindinganiso ezifanele kanye nezidingo zoku-oda, kanye nokuhlinzeka abasebenzisi ngemikhiqizo yensimbi emise okwe-H engcono kakhulu.

ISICELO

Isetshenziswe ezidingweni ezahlukene zesakhiwo sensimbi, kungakhathaliseki ukuthi ingaphansi kwe-torque egobayo, umthwalo wengcindezi, umthwalo we-eccentric ubonisa ukusebenza kwawo okuphezulu, ungathuthukisa kakhulu umthamo wokuthwala kunokuvamile.H Ingxenye Beam, ukonga insimbi 10% ~ 40%. Insimbi emise okwe-H ine-flange ebanzi, iwebhu encane, imininingwane eminingi, kanye nokusetshenziswa okuguquguqukayo, okungasindisa u-15% kuya ku-20% wensimbi ezakhiweni ezihlukahlukene ze-truss. Ngenxa yokuthi i-flange yayo ihambisana ngaphakathi nangaphandle, futhi ukuphela komkhawulo ku-Angle efanele, kulula ukuhlanganisa nokuhlanganisa izingxenye ezihlukahlukene, ezingasindisa cishe u-25% we-welding kanye nomthwalo we-riveting, futhi ungasheshisa kakhulu isivinini sokwakhiwa kwephrojekthi futhi unciphise isikhathi sokwakha.

UKUPAKA KANYE NOKUTHUMELA

Ngaphambi kokuthunyelwa, qiniseka ukuthi insimbi emise okwe-H ipakishwe kahle futhi ivikelekile ukuze kuvinjelwe ukunyakaza noma ukungqubuzana ngesikhathi sokuthutha. Izinto zokupakisha ezifanele kanye nezakhiwo, njengamabhande ensimbi, izinkuni ze-cushion, njll. zingasetshenziswa ukuze kuqinisekiswe ukuzinza nokuphepha kwensimbi emise okwe-H.

Ngokuya ngosayizi, isisindo kanye nebanga lokuhamba lensimbi emise okwe-H nezinye izici, khetha imodi yokuthutha efanele. Kwezokuthutha ezihamba amabanga amafushane, ezokuthutha zomgwaqo zingakhethwa, kusetshenziswa amaloli noma ezinye izinto zokuhamba zomgwaqo; Ezokuthutha ezihamba amabanga amade, ezokuthutha ngezitimela zingase zifaneleke kakhulu ngoba zingathwala inani elikhulu lama-H-beam futhi zizinzile; Uma uhwebo lwamazwe ngamazwe noma ezokuthutha zasolwandle zamabanga amade zidingeka, ukuthutha ngamanzi kungase kube inketho enhle; Esimeni esiphuthumayo noma izidingo zesikhathi esiphezulu, ungakhetha ukuthutha ngendiza.

AMANDLA ENKAMPANI

Kwenziwe eChina, isevisi yezinga lokuqala, ikhwalithi esezingeni eliphezulu, edume umhlaba wonke

1. Umphumela wesilinganiso: Inkampani yethu inochungechunge olukhulu lokuhlinzeka ngempahla kanye nemboni enkulu yensimbi, ezuza imiphumela yesilinganiso kwezokuthutha nokuthenga, futhi iba inkampani yensimbi ehlanganisa ukukhiqiza kanye nezinsizakalo.

2. Ukuhlukahluka komkhiqizo: Ukuhlukahluka komkhiqizo, noma iyiphi insimbi oyifunayo ingathengwa kithi, ikakhulukazi ehileleke ezakhiweni zensimbi, izinsimbi zensimbi, izinqwaba zeshidi lensimbi, amabakaki e-photovoltaic, insimbi yesiteshi, amakhoyili ensimbi ye-silicon neminye imikhiqizo, okwenza kube lula kakhulu Khetha uhlobo lomkhiqizo olufunayo ukuhlangabezana nezidingo ezahlukene.

3. Ukunikezwa okuzinzile: Ukuba nolayini wokukhiqiza ozinzile kanye nochungechunge lokuhlinzeka kunganikeza ukuhlinzekwa okuthembekile. Lokhu kubaluleke kakhulu kubathengi abadinga amanani amakhulu ensimbi.

4. Ithonya lomkhiqizo: Yiba nomthelela womkhiqizo ophezulu kanye nemakethe enkulu

5. Isevisi: Inkampani enkulu yensimbi ehlanganisa ukwenza ngokwezifiso, ukuthutha nokukhiqiza

6. Ukuncintisana kwentengo: intengo enengqondo

7. SiyahlinzekaUhlaka lwe-ASTM W14x82, Uhlaka lwe-ASTM W30x132, i-ASTM W30x132 beam, futhi isekela i-Custom W8x40 H Beam, i-W16x89 H Yangokwezifiso

*Thumela i-imeyili ku[i-imeyili ivikelwe]ukuze uthole ikhotheshini yamaphrojekthi akho

FAQ

1.Ngingayithola kanjani ikhotheshini kuwe ?

Ungasishiyela umlayezo, futhi sizophendula yonke imilayezo ngokuhamba kwesikhathi.

2.Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo yekhwalithi engcono kakhulu nokulethwa ngesikhathi. Ukwethembeka kuwumgomo wenkampani yethu.

3.Ngingakwazi ukuthola amasampula ngaphambi koku-oda?

Yebo kunjalo. Ngokuvamile amasampula ethu amahhala, singakhiqiza ngamasampula akho noma imidwebo yobuchwepheshe.

4.Ithini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esivamile ngu-30% wediphozithi, futhi ukuphumula uma kuqhathaniswa ne-B/L. EXW, FOB,CFR,CIF.

5.Ingabe uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngokuphelele.

6.Siyethemba kanjani inkampani yakho?

Sisebenza ngokukhethekile ebhizinisini lensimbi iminyaka eminingi njengomphakeli wegolide, indlunkulu itholakala esifundazweni saseTianjin, siyakwamukela ukuphenya nganoma yiziphi izindlela, ngazo zonke izindlela.