I-GB 1200 × 2400 Steel Grating Isetshenziselwa Ukwakhiwa Okukhulu Nokwakhiwa Kwekhwalithi Ephezulu

| Igama lomkhiqizo | I-grating yensimbi enamazinyo |

| Isitayela sokuklama | Imodemu |

| Izinto | Ukushisa Okushisayo, okwenziwe ngezifiso |

| Isisindo | 7-100kg |

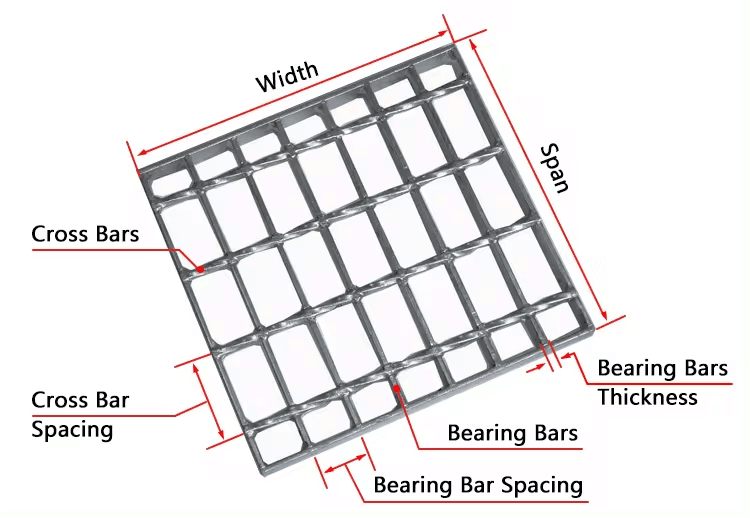

| Ibha Yokuthwala | 253/ 255/303/325/ 405/553/655 |

| Iphimbo lebha yokuthwala | 30mm 50mm 100mm |

| Isici | Ukumelana Okuhle Kakhulu Nokugqwala, Okungasheleli |

| Impahla eluhlaza | Insimbi Eshisayo Ecwiliswe Ngogesi Q235 |

| Okujwayelekile | Amazinga aseYurophu, GB/T13912-2002, BS729, AS1650 |

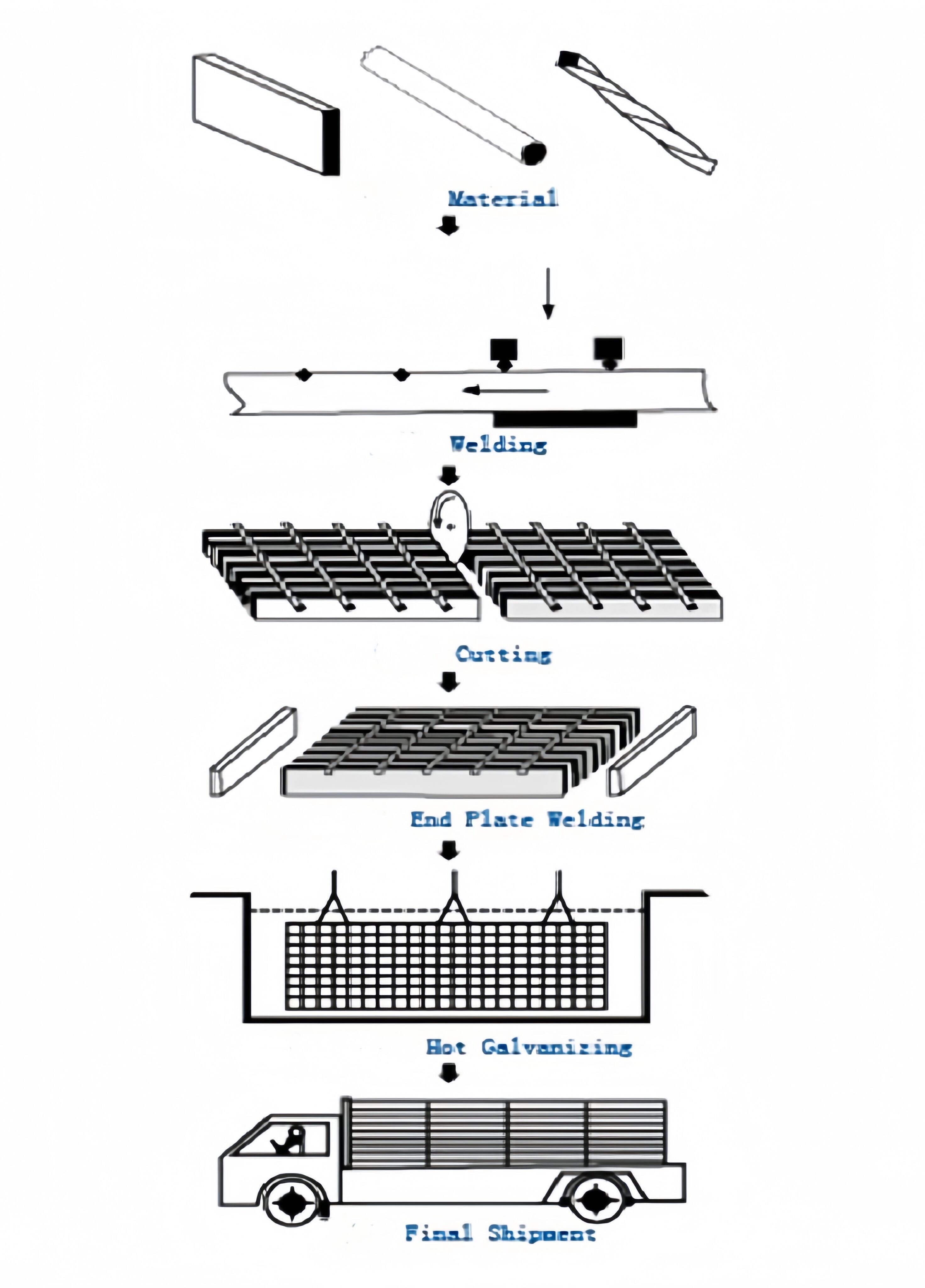

| Indlela Yokushisela | Ukushisela Ukumelana Nokucindezela Okuzenzakalelayo |

| Ikholomu yeshadi | izimpahla ezingenalutho phakathi | Indawo ebukhoma | Imininingwane ye-Layisha eyisicaba ye-mesh (ububanzi nobukhulu) | |||||||

| 20x3 | 25x3 | 32x3 | 403 | 20x5 | 25x5 | |||||

| 1 | 30 | 100 | I-G20330100 | E25230H00 | C32380F100 | G40230100 | E205/30100 | E255/307100 | ||

| 50 | G20230/50 | C253/20/50 | C2233050 | 640340100 | C205/00/50 | C255/30/50 | ||||

| 2 | 40 | 100 | 6203/401100 | 8253/40100 | E323/401100 | 640340100 | 8205/40/100 | 5255/40/100 | ||

| 50 | I-G20340/50 | G250/40/50 | G223/4050 | G403140/50 | 205/4/50 | G255/4050 | ||||

| 3 | 60 | 50 | G203460/50 | C25360/50 | 5253/6050 | 3403480150 | C205/60/50 | G255/60150 | ||

| Ikholomu yeshadi | izimpahla ezingenalutho phakathi | Indawo ebukhoma | Imininingwane ye-Layisha eyisicaba ye-mesh (ububanzi nobukhulu) | |||||||

| 32×5 | 40x5 | 45x5 | 5045 | 55×5 | 80x5 | |||||

| 1 | 30 | 100 | I-G325301100 | G40530H00 | C45580100 | G50530100 | G555/30100 | E805/30/100 | ||

| 50 | G325/30/50 | C405/20/50 | G455/3050 | S505/30/50 | 55500/50 | G605/8050 | ||||

| 2 | 40 | 100 | 8325401100 | 840540100 | 455/40100 | G50540100 | 8555/40/100 | 2605/40/100 | ||

| 50 | G32540/50 | C405/40/50 | G4554050 | G505/40/50 | E555/40/50 | G605/40150 | ||||

| 3 | 60 | 50 | G225.6051 | C405/6A/50 | G4556050 | G50560/50 | 6555/6050 | G6056051 | ||

I-GB Steel Grating

Okujwayelekile: GB/T 700-2006

YB/T4001.1-2007

Izici

I-ASTM A36 grating yensimbiikhiqizwa kusetshenziswa insimbi ephansi yekhabhoni enokushibilika okuhle kakhulu kanye nokwakheka kahle. Yaziwa ngamandla ayo aphezulu kanye nomthamo omangalisayo wokuthwala umthwalo. Lokhu kwenza i-A36 steel grating ifaneleke kakhulu ekusetshenzisweni kwemisebenzi enzima ezindaweni zezimboni, njengezindawo zokwakha, izitshalo zokukhiqiza, kanye nezindawo ze-petrochemical. Inikeza ukumelana okuthuthukisiwe ngokumelene nokushaqeka, ukushisa, kanye nokugqwala, okuqinisekisa impilo ende ngisho nasezindaweni ezinzima.

I-grill yensimbi egayiweikhiqizwa ngokumboza insimbi ngesendlalelo se-zinc, enikeza isivikelo esiphezulu ekugqwaleni nasekugqwaleni. Inqubo yokufaka i-galvanization ithuthukisa isikhathi eside se-grating, okwenza ifaneleke ukufakwa kwangaphandle noma izindawo ezivezwe umswakama nezinto ezigqwalisayo. I-grating ehlanganisiwe ivame ukusetshenziswa ezindleleni zokuhamba ngezinyawo, izinhlelo zokukhipha amanzi, kanye namapulatifomu, lapho ubuso bayo obungasheleli bunezela khona isendlalelo esengeziwe sokuphepha.

Umehluko omkhulu phakathi kwe-ASTM A36 steel grating kanye ne-galvanized steel grating usezicini zazo zokumelana nokugqwala. Ngenkathi i-ASTM A36 grating inikeza izinga eliyisisekelo lokumelana nokugqwala, i-galvanized coating e-steel grating inikeza isivikelo esiphezulu, yandisa kakhulu isikhathi sayo sokuphila. I-galvanized steel grating iyanconywa lapho ukuvimbela ukugqwala kubaluleke kakhulu.

Isicelo

I-grit yensimbi, umkhiqizo oguquguqukayo futhi ohlala isikhathi eside, ithole ukuthandwa okukhulu ngenxa yezinhlelo zayo eziningi emikhakheni eyahlukahlukene. Njengoba yakhiwe ngemigoqo noma amapuleti ensimbi axhumene, i-grit yensimbi inikeza amandla akhethekile, ukuzinza, kanye namakhono okukhipha amanzi.

1. Umkhakha Wezimboni:

Umkhakha wezimboni usebenzisa kakhulu i-grit yensimbi ngenxa yamandla ayo angenakuqhathaniswa kanye nezici zokuphepha. Ivame ukusetshenziswa njengephansi emafektri nasezindaweni zokugcina impahla, ihlinzeka ngendawo ezinzile yemishini esindayo futhi inika abasebenzi indawo evikelekile. I-grit yensimbi isetshenziselwa futhi ama-catwalk, amapulatifomu aphakanyisiwe, kanye nama-mezzanine, okunikeza indlela ephephile yabasebenzi yokufinyelela ezindaweni ezahlukene ngaphakathi kwesikhungo.

2. Imboni Yokwakha:

Embonini yokwakha, i-grit yensimbi ibaluleke kakhulu. Isetshenziswa kabanzi njengepulatifomu ye-scaffolding, inikeza indawo yokusebenza eqinile nephephile yabasebenzi abasezingeni eliphezulu. Njengoba inomthamo omkhulu wokuthwala imithwalo, i-grit yensimbi iqinisekisa ukuphepha kwabasebenzi bokwakha phakathi nezigaba ezahlukene zephrojekthi. Ngaphezu kwalokho, i-grit yensimbi ingenziwa ngokwezifiso ukuze ihlangabezane nezidingo ezithile, okwenza kube ukukhetha okuthandwayo kokwakha izindlela zokuhamba, izitebhisi, kanye nezembozo zokudonsa amanzi ngaphakathi kwezakhiwo.

3. Umkhakha Wezokuthutha:

Ngenxa yesilinganiso sayo esihle kakhulu samandla nesisindo, i-grit yensimbi isetshenziswa kakhulu emkhakheni wezokuthutha. Isetshenziswa kabanzi ekudaleni izindlela zokuhamba eziqinile, ezingasheleli kanye nezindawo zokulungisa izitebhisi ezindaweni zokulungisa izimoto, ezikhumulweni zezindiza, eziteshini zesitimela, nasezindaweni zokupaka imikhumbi. Lezi zixazululo ze-grit zithuthukisa ukuphepha futhi zivumela ukunyakaza okuphumelelayo, ngisho nasezimweni zezulu ezinzima.

4. Imboni Yamandla Nowoyela:

Imboni yamandla namafutha ithembele kakhulu ekufakeni insimbi ukuze ihlale isikhathi eside futhi imelane nokugqwala. Ukufakeni insimbi kuvame ukusetshenziswa ezindaweni zokuhlanza uwoyela, ezitshalweni zikagesi, nasezindaweni zokucubungula amakhemikhali. Kusebenza njengesixazululo esifanele sophansi, ikakhulukazi ezindaweni ezivezwe uketshezi, amakhemikhali, kanye namazinga okushisa aphezulu, okuqinisekisa ukuphepha kwabasebenzi kanye nokuvimbela izingozi.

5. Izicelo Zezentengiselwano Nezokwakha:

I-grit yensimbi nayo ithola indlela yayo emisebenzini yezentengiselwano neyokwakha. Ukubukeka kwayo okuhle, kanye nezinzuzo zayo zokusebenza, kuyenza ibe yisinqumo esihle kakhulu sokudala ama-facade anesitayela, ama-sunshades, kanye nezikrini zokuhlobisa. I-grit yensimbi ingasetshenziswa futhi njengezinto zobuciko ezindaweni zasemadolobheni, okunikeza kokubili ukukhanga okubonakalayo kanye nokusebenza.

UKUBONISWA KOMKHIQIZO

UKUPHAKISHA NOKUTHUMELA

UKUVAKASHELA KWAMAKHASIMENDE

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, kanye nokuphumula ngokumelene ne-B/L.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.