Isakhiwo Esisheshayo Sokwakha Isakhiwo Sensimbi Esilungisiwe Esilungisiwe Isakhiwo Sensimbi Esilengayo

Nakuba ubukhulu bensimbi buphakeme kunobezinye izinto zokwakha, amandla ayo aphezulu kakhulu. Ngaphansi kokucindezeleka okufanayo, isakhiwo sensimbi sinesisindo esincane futhi singenziwa sibe isakhiwo esinobubanzi obukhulu.

Isakhiwo sangaphakathi sensimbi siyafana futhi si-isotropic. Ukusebenza kwangempela kwesakhiwo sensimbi kuvumelana kahle nemiphumela yokubala yethiyori esetshenzisiwe, ngakho-ke ukuthembeka kwesakhiwo kuphezulu.

*Thumela i-imeyili ku-[i-imeyili ivikelwe]ukuthola ikhotheshini yamaphrojekthi akho

| Uhlu Lwezinto Ezibalulekile | |

| Iphrojekthi | |

| Usayizi | Ngokusho Kwesidingo Samakhasimende |

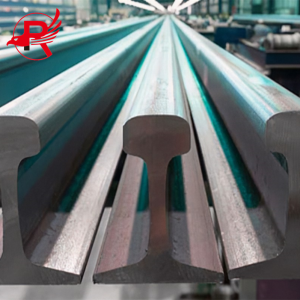

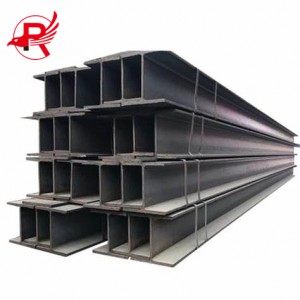

| Uhlaka Lwesakhiwo Sensimbi Eyinhloko | |

| Ikholomu | Insimbi Yesigaba se-H Ehlanganisiwe ye-Q235B, Q355B |

| Umsebe | Insimbi Yesigaba se-H Ehlanganisiwe ye-Q235B, Q355B |

| Uhlaka Lwesakhiwo Sensimbi Yesibili | |

| I-Purlin | Insimbi Yohlobo lwe-Q235B C no-Z |

| Ibhande Lamadolo | Insimbi Yohlobo lwe-Q235B C no-Z |

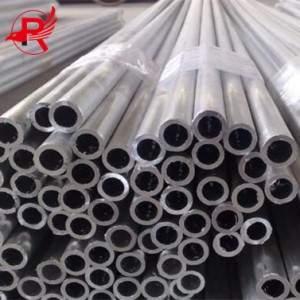

| Ishubhu Lokubopha | Ipayipi Lensimbi Eliyindilinga le-Q235B |

| I-brace | Ibha Eyindilinga ye-Q235B |

| Ukusekelwa Okuqondile Nokuvundlile | Insimbi Engange ye-Q235B, Ibha Eyindilinga noma Ipayipi Lensimbi |

INQUBO YOKUKHIQIZWA KOMKHIQIZO

INZUZO

Yiziphi izinzuzo kanye nokungalungi kobunjiniyela besakhiwo sensimbi?

1. Izinto ezibonakalayo zinamandla aphezulu kanye nesisindo esilula

Insimbi inamandla aphezulu kanye ne-modulus enwebekayo ephezulu. Uma iqhathaniswa nokhonkolo kanye nokhuni, isilinganiso sobuningi bayo namandla okukhiqiza siphansi kakhulu. Ngakho-ke, ngaphansi kwezimo ezifanayo zokucindezeleka, isakhiwo sensimbi sinengxenye encane yezingxenye, isisindo esincane, ukuthuthwa okulula nokufakwa, futhi kufanelekile ezindaweni ezinkulu, ukuphakama okuphezulu, kanye nemithwalo esindayo. Isakhiwo.

2. Insimbi inokuqina, i-plasticity enhle, indwangu efanayo, kanye nokuthembeka okuphezulu kwesakhiwo.

Ifanele ukumelana nokushayisana kanye nemithwalo enamandla, futhi inokumelana okuhle kokuzamazama komhlaba. Isakhiwo sangaphakathi sensimbi siyafana futhi siseduze nomzimba ofana nowe-isotropic. Ukusebenza kwangempela kwesakhiwo sensimbi kuhambisana kakhulu nombono wokubala. Ngakho-ke, isakhiwo sensimbi sinokwethenjelwa okuphezulu.

3. Ukukhiqizwa nokufakwa kwesakhiwo sensimbi kwenziwa ngomshini kakhulu

Izingxenye zesakhiwo sensimbi kulula ukuzikhiqiza emafektri futhi zihlanganiswe ezindaweni zokwakha. Ukukhiqizwa kwezingxenye zesakhiwo sensimbi ngomshini efektri kunokunemba okuphezulu, ukusebenza kahle kokukhiqiza okuphezulu, ukuhlanganiswa kwesiza sokwakha okusheshayo, kanye nesikhathi esifushane sokwakha. Isakhiwo sensimbi yisakhiwo esithuthuke kakhulu kwezimboni.

4. Isakhiwo sensimbi sisebenza kahle ekuvaleni

Njengoba isakhiwo esihlanganisiwe singavalwa ngokuphelele, singenziwa sibe yimikhumbi enomfutho ophezulu, amachibi amakhulu kawoyela, amapayipi omfutho, njll. anomoya oqinile futhi amanzi aqinile.

5. Isakhiwo sensimbi simelana nokushisa kodwa asimelani nomlilo

Uma izinga lokushisa lingaphansi kuka-150°C, izakhiwo zensimbi azishintshi kakhulu. Ngakho-ke, isakhiwo sensimbi sifanelekela ama-workshop ashisayo, kodwa uma ubuso besakhiwo bungaphansi kwemisebe yokushisa engaba ngu-150 degrees Celsius.°C, kumele ivikelwe ngamaphaneli okuvikela ukushisa. Uma izinga lokushisa lingu-300℃-400℃Amandla kanye ne-modulus enwebekayo yensimbi kokubili kwehla kakhulu. Uma izinga lokushisa licishe libe ngu-600°C, amandla ensimbi avame ukuba yi-zero. Ezakhiweni ezinezidingo ezikhethekile zomlilo, isakhiwo sensimbi kumele sivikelwe ngezinto eziphikisayo ukuze kuthuthukiswe izinga lokumelana nomlilo.

IDIPOZITHI

Uphahla luvame ukuba nezingqimba ezingangeni manzi, amaphaneli ophahla, imishayo, amapayipi emishini, uphahla, njll. Amaphaneli ophahla awagcini nje ngokuba yizingxenye ezithwala umthwalo, kodwa futhi ayi-interface ehlukanisa isikhala esiphezulu nendawo yangaphandle.

Uphahla luyindawo ebiyelwe ephezulu kakhuluIzakhiwo Zesakhiwo SensimbiKufanele ihlangabezane nezidingo zokusebenza ezifanele futhi ihlinzeke ngendawo efanelekile yangaphakathi yesakhiwo.

Umsebenzi nezidingo zophahla: Uphahla luyisimbozo esiphezulu sendlu, esakhiwe uphahla kanye nesakhiwo esisekelayo. Umsebenzi wokuvikela uphahla ukuvimbela ukuhlasela kwemvula yemvelo, iqhwa kanye neziphepho zesihlabathi kanye nethonya lemisebe yelanga. Ngakolunye uhlangothi, kumele luthwale umthwalo engxenyeni engenhla yophahla, okuhlanganisa umthwalo womoya kanye neqhwa, isisindo sophahla, kanye nesisindo sezingxenye ezingaba khona kanye nabantu, bese luwudlulisela odongeni. Ngakho-ke, izidingo zophahla kufanele zibe namandla futhi ziqine, zibe nesisindo esincane, futhi zibe nezakhiwo ezingangeni manzi, ezingashisi umlilo, ezingashisi ukushisa kanye nezingashisi ukushisa. Ngesikhathi esifanayo, izingxenye kudingeka zibe lula, zibe lula ukwakhiwa, futhi zikwazi ukubambisana nesakhiwo sonke ukuze zibe nokubukeka okuhle.

UKUHLOLWA KOMKHIQIZO

Izakhiwo ZensimbiUkuxhumeka kuyisixhumanisi esibalulekile kubunjiniyela besakhiwo sensimbi. Ikhwalithi yokuxhumeka ithinta ngqo ukuphepha kanye nokuqina kwephrojekthi yonke yesakhiwo sensimbi. Ukuhlolwa kokuxhumeka kwesakhiwo sensimbi kuhlanganisa ikakhulukazi izici ezimbili ezilandelayo:

1. Ukuhlolwa kwekhwalithi yokushisela: okuhlanganisa ukuhlolwa kwekhwalithi yokubukeka kokushisela, amaphutha angaphakathi kanye nezinye izinkomba zokuhlola ukuthi ikhwalithi yokushisela iyahlangabezana yini nezidingo ezibekiwe.

2. Ukutholwa kokuxhumeka kwebholidi elinamandla aphezulu: Amabholidi anamandla aphezulu angenye yezindlela zokuxhuma ezisetshenziswa kakhulu ekuxhumaneni kwesakhiwo sensimbi. Ukuhlola ikhwalithi yokuxhumeka kanye nezinga lokuqinisa kungaqinisekisa ukuzinza nokuphepha kokuxhumeka.

IPHROJEKTHI

Inkampani yethu ivame ukuthumela kwamanye amazweIzakhiwo Zensimbi Ezilungisiweimikhiqizo eya eMelika kanye namazwe aseNingizimu-mpumalanga ye-Asia. Sihlanganyele komunye wemiklamo eMelika enendawo engaba amamitha-skwele angu-543,000 kanye nokusetshenziswa okuphelele kwamathani angaba ngu-20,000 ensimbi. Ngemva kokuba iphrojekthi isiqediwe, izoba yinkimbinkimbi yesakhiwo sensimbi ehlanganisa ukukhiqiza, indawo yokuhlala, ihhovisi, imfundo kanye nezokuvakasha.

ISICELO

Insimu yokwakha:Izakhiwo Zesakhiwo Sensimbiziye zasetshenziswa kabanzi ezakhiweni zesimanje, okuhlanganisa izakhiwo eziphakeme, izitshalo zezimboni, izakhiwo zezentengiselwano, izinkundla zemidlalo, amahholo ombukiso, iziteshi, amabhuloho, njll. Izakhiwo zensimbi zinezinzuzo zesisindo esilula, amandla aphezulu, isivinini sokwakha esisheshayo, kanye nokumelana okuhle nokuzamazama komhlaba. Zingahlangabezana nezidingo zezakhiwo zesimanje zokuphepha kwesakhiwo, ukonga, kanye nokuvikelwa kwemvelo.

Ubunjiniyela bamabhuloho: Izakhiwo zensimbi zisetshenziswe kabanzi kubunjiniyela bamabhuloho, okuhlanganisa amabhuloho emigwaqo, amabhuloho esitimela, amabhuloho abahamba ngezinyawo, amabhuloho ahlala ngekhebula, amabhuloho okulenga, njll. Izakhiwo zensimbi zinezinzuzo zesisindo esilula, amandla aphezulu, ukwakhiwa okulula, kanye nokuqina okuhle, futhi zingahlangabezana nezidingo zobunjiniyela bamabhuloho ukuze kuphephe futhi kongiwe izakhiwo.

Insimu yokukhiqiza imishini: Izakhiwo zensimbi zisetshenziswe kabanzi emkhakheni wokukhiqiza imishini, okuhlanganisa amathuluzi emishini ahlukahlukene, imishini yokunyathelisa, izitofu zezimboni, imishini yokugoqa, ama-crane, ama-compressor, imishini yokudlulisa, njll. Izakhiwo zensimbi zinezinzuzo zamandla aphezulu, ukuqina okuhle, kanye nokucutshungulwa okulula, futhi zingahlangabezana nezidingo zokunemba kwemishini kanye nokuzinza emkhakheni wokukhiqiza imishini.

UKUPHAKISHA NOKUTHUMELA

Isakhiwo Sensimbi Isakhiwo Sensimbikudingeka zipakishwe ngesikhathi sokuthunyelwa ukuze kuvikelwe ukuphepha nobuqotho bezimpahla futhi kuvinjelwe ukuthi izimpahla zingalimali futhi zilahleke ngesikhathi sokuthutha. Lokhu okulandelayo yizidingo eziyisisekelo zokupakisha ukuthunyelwa kwesakhiwo sensimbi:

1. Izinto zokupakisha: Izinto zokupakisha ezifanele kumele zisetshenziswe ekupakisheni. Kubandakanya ukhuni, amabhodi okhuni, amapuleti ensimbi, amabhokisi ensimbi, amabhokisi okhuni, amaphalethi okhuni, njll., qinisekisa ukuthi izinto zokupakisha zinamandla nokuqina okwanele.

2. Ukubopha amaphakheji: Amaphakheji ezakhiwo zensimbi kufanele aboshwe futhi aqine, ikakhulukazi izinto ezinkulu. Kumele afakwe futhi aqiniswe kuma-pallet noma ezisekelweni ukuze kuvinjelwe ukugudluka noma ukuthuthumela ngesikhathi sokuthuthwa.

3. Ubushelelezi: Ukubukeka kwesakhiwo sensimbi kumele kube bushelelezi, futhi akumelwe kube namakhona noma imiphetho ebukhali ukuze kugwenywe ukulimaza ezinye izimpahla noma ukubeka ukuphepha komuntu siqu kwabasebenzi engozini.

4. Ingangeni umswakama, ingangenwa ukushaqeka, futhi ingagugi: Izinto zokupakisha kufanele zihambisane nemithetho yokuthumela futhi zingangenwa umswakama, zingangenwa ukushaqeka, futhi zingagugi. Ikakhulukazi ngesikhathi sokuthuthwa olwandle, kufanele kuqashelwe amaphepha angangenwa umswakama, angangenwa umswakama, angangenwa umswakama kanye nezinye izindlela zokwelapha ukuvimbela isakhiwo sensimbi ukuthi singagugi, sigqwale, futhi sigugiswe amanzi olwandle.

AMANDLA ENKAMPANI

Kwenziwe eShayina, isevisi yekilasi eliphezulu, ikhwalithi ephezulu, idumile emhlabeni jikelele

1. Umphumela Wesilinganiso: Inkampani yethu inochungechunge olukhulu lokuhlinzeka kanye nefektri enkulu yensimbi, efinyelela imiphumela emikhulu kwezokuthutha kanye nokuthengwa kwempahla, futhi iba yinkampani yensimbi ehlanganisa ukukhiqiza kanye nezinsizakalo.

2. Ukwehlukahluka komkhiqizo: Ukwehlukahluka komkhiqizo, noma iyiphi insimbi oyifunayo ingathengwa kithi, ikakhulukazi ehilelekile ezakhiweni zensimbi, izinsimbi zensimbi, izinqwaba zeshidi lensimbi, amabhulakhethi e-photovoltaic, insimbi yesiteshi, amakhoyili ensimbi ye-silicon neminye imikhiqizo, okwenza kube lula ukukhetha uhlobo lomkhiqizo olufunayo ukuze luhlangabezane nezidingo ezahlukene.

3. Ukunikezwa okuzinzile: Ukuba nomugqa wokukhiqiza ozinzile kanye nochungechunge lokunikezwa kunganikeza ukunikezwa okuthembekile. Lokhu kubaluleke kakhulu kubathengi abadinga insimbi eningi.

4. Ithonya lomkhiqizo: Linethonya lomkhiqizo eliphezulu kanye nemakethe enkulu

5. Isevisi: Inkampani enkulu yensimbi ehlanganisa ukwenza ngokwezifiso, ezokuthutha kanye nokukhiqiza

6. Ukuncintisana kwentengo: intengo enengqondo

*Thumela i-imeyili ku-[i-imeyili ivikelwe]ukuthola ikhotheshini yamaphrojekthi akho

UKUVAKASHELA KWAMAKHASIMENDE