Imikhiqizo

-

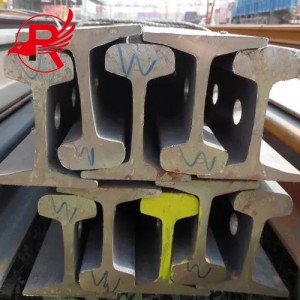

Isitimela Sensimbi se-ISCOR Isitimela Sensimbi Isitimela Esikhanyayo Imayini Yamalahle Isitimela Sesitimela Sezimayini

Isitimela Sensimbi se-ISCORyizona zinto eziyinhloko zemizila yesitimela. Umsebenzi wayo ukuqondisa amasondo esitokisi esigingqikayo phambili, ukuthwala ingcindezi enkulu yamasondo, bese uyidlulisela kubantu abalele. Imizila kumele ihlinzeke ngendawo yokugingqika eqhubekayo, ebushelelezi futhi engamelani kakhulu namasondo. Ezigabeni zesitimela ezisebenzisa ugesi noma zamabhulokhi azenzakalelayo, imizila ingasebenza futhi njengezifunda zethrekhi.

-

Isitimela Sesitimela Sensimbi se-ISCOR Izitimela Zensimbi Ezikhanyayo Ithrekhi I-Crane Isitimela Sesitimela Sesitimela Sensimbi Esikhanyayo

Isitimela Sensimbi se-ISCOR siyingxenye ebalulekile futhi ebalulekile ekwakhiweni nasekusebenzeni kwezitimela. Sinezici zokuthwala umthwalo oqinile, ukumelana nokuguguleka kanye nokumelana nokugqwala. Ngokuthuthukisa ukusebenza kahle kwezitimela, ukuqinisekisa ukuphepha kwezitimela, ukukhuthaza intuthuko yezomnotho, ukonga izinsiza zamandla, njll., sidlala indima ebalulekile ekuthuthukisweni kwezwe. Intuthuko ibaluleke kakhulu emasu.

-

Isitimela Sesitimela I-ISCOR Isitimela Sensimbi Isitimela Esinzima Sensimbi

Ukusebenza kahle kwesitimela sensimbi se-ISCOR: Ukusetshenziswa kwesitimela sensimbi kunganciphisa ukumelana nomsindo wezitimela, kuthuthukise ukusebenza kahle kwesitimela, kusheshise izitimela, kunciphise isikhathi sokuhamba, futhi kuthuthukise ikhwalithi yesevisi.

-

Isitimela Sensimbi se-ISCOR/Isitimela Sensimbi/Isitimela Sesitimela/Isitimela Esilungisiwe Ngokushisa

I-ISCOR Steel Rail inamandla aphezulu. Ngenxa yokuthi yenziwe ngensimbi enamandla aphezulu, ubulukhuni bayo buphezulu kakhulu (uma kuqhathaniswa nemigoqo yensimbi evamile), futhi ingamelana nokucindezela okukhulu kanye nemithwalo yokushayisana ngaphandle kokulimala; futhi inokuqina okuhle: okungukuthi, inamandla aphezulu okumelana nokushayisana okuphindaphindiwe. Ngakho-ke, amathuba okuwa kwesethi yamasondo angancishiswa kakhulu futhi isici sokuphepha sokushayela singathuthukiswa.

-

Umkhiqizi Wesitimela Sensimbi Se-ISCOR Ukukhanya Kwesitimela Sensimbi

Isitimela Sensimbi se-ISCORNjengesakhiwo sobunjiniyela obuhlanganisiwe, ithrekhi ibekwe eceleni komgwaqo, idlala indima eqondisayo ekusebenzeni kwesitimela, futhi ithwala ngqo ingcindezi enkulu yesitokwe esigoqekayo kanye nomthwalo waso. Ngaphansi kwamandla okusebenza kwesitimela, izingxenye zaso ezahlukahlukene kumele zibe namandla anele kanye nokuqina ukuqinisekisa ukuthi isitimela sisebenza ngokuphepha, ngokushelela nangokungaphazanyiswa ngesivinini esiphezulu esibekiwe.

-

Isitimela Sensimbi Se-ISCOR Sezinga Eliphezulu Sezimboni Zokumbiwa Kwezitimela Sensimbi Esingu-9kg

Ubude be-ISCOR Steel Rail ezweni lakithi buyi-12.5m kanye no-25m. Kuma-rails angu-75kg/m, kunobude obubodwa kuphela obuyi-25m. Kukhona futhi ama-rails amafushane emicu yangaphakathi yama-curve. Ku-12.5m standard Huai rail series, kune-short rails ezintathu: 40mm, 80mm, kanye no-120mm; ku-25m rail, kune-short rails ezintathu: 40mm, 80mm, kanye no-160mm.

-

Umkhiqizi Wesitimela Sensimbi Esinzima Se-ISCOR

Izinhlobo zeIsitimela Sensimbi se-ISCORNgokuvamile zihlukaniswa ngesisindo. Isibonelo, isitimela esingu-50 esivame ukuthi sibhekisela kusitimela esinesisindo esingu-50kg/m, njalo njalo, kunezitimela ezingu-38, izitimela ezingu-43, izitimela ezingu-50, izitimela ezingu-60, izitimela ezingu-75, njll., vele. Kukhona futhi izitimela ezingu-24 kanye nezitimela ezingu-18, kodwa zonke lezo ziyizincwadi ezindala. Phakathi kwazo, izitimela ezinezitimela ezingu-43 nangaphezulu ngokuvamile zibizwa ngokuthi izitimela ezisindayo.

-

Isitimela Sesitimela Sensimbi Se-ISCOR Isitimela Sensimbi Esinzima Sesitimela Esijwayelekile Sesitimela

Umsebenzi we-I-ISCOR Steel RaiI-l iwukuqondisa amasondo esitokisi esigingqikayo phambili, ukuthwala ingcindezi enkulu yamasondo, bese uyidlulisela kubantu abalele. Ama-rails kumele ahlinzeke ngendawo yokugingqika eqhubekayo, ebushelelezi futhi engamelani kakhulu namasondo. Ezigabeni zesitimela ezisebenzisa ugesi noma zamabhulokhi azenzakalelayo, ama-rails angasebenza futhi njengezifunda zethrekhi.

-

Umhlinzeki Wesitimela Sesitimela Sensimbi se-ISCOR Umkhiqizi Wesitimela Sensimbi

Isitimela Sensimbi se-ISCORinikeza amandla aphezulu nokuqina. Ngenxa yokuthi imizila yesitimela idinga ukumelana nesisindo sezitimela kanye nomthelela wokugijima, insimbi yesitimela kumele ibe namandla nokuqina okwanele.

-

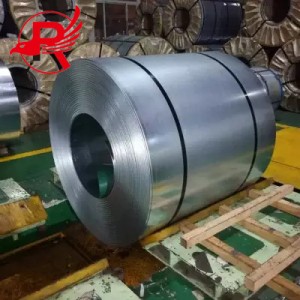

Amakhoyili/Imichilo Yensimbi Ye-Silicon Eqondiswe Okusanhlamvu Okujwayelekile Okuqoqwe Ngokubandayo kwe-GB, Ikhwalithi Enhle, Ukulahlekelwa Yinsimbi Okuphansi

Ngenxa yokumelana kwayo nokugqwala, ukuqina okuphezulu, kanye namandla aphezulu, insimbi ye-silicon isetshenziswa kabanzi ekukhiqizweni kwezingxenye ezithile ezikhethekile ezindizeni, emishinini, ezimotweni nakwezinye izinkambu.

Ngamafuphi, insimbi ye-silicon, njengohlobo lwepuleti lensimbi eligoqekile elibandayo elinezakhiwo ezikhethekile, idlala indima ebalulekile emikhakheni yezimboni nezobuchwepheshe, futhi amasimu okusetshenziswa kwayo asakhula. -

I-GB Standard DC06 B35ah300 B50A350 35W350 35W400 Ikhoyili Yensimbi Kagesi Engaguquki Engaguquki Engaguquki Engaguquki Eyi-Silicon

Izidingo zokusebenza kwensimbi ye-silicon

1. Ukulahlekelwa yinsimbi okuphansi, okuyisibonakaliso esibaluleke kakhulu sekhwalithi yamashidi ensimbi e-silicon. Wonke amazwe ahlukanisa amamaki ngokwenani lokulahlekelwa yinsimbi. Uma ukulahlekelwa yinsimbi kuphansi, kulapho izinga liphakama khona.

2. Ukuqina kokufakwa kwamandla kazibuthe (ukufakwa kwamandla kazibuthe) kuphezulu ngaphansi kwensimu enamandla kazibuthe, okunciphisa ivolumu nesisindo semiphetho yama-motor nama-transformer, okusindisa amashidi ensimbi e-silicon, izintambo zethusi, nezinto zokuvikela. -

I-GB Standard Non-Oriented Electrical Silicon Steel Cold Rolled Silicon Steel Coil

Izidingo zokusebenza kwensimbi ye-silicon ziyizi: ① Ukulahlekelwa yinsimbi okuphansi, okuyisibonakaliso esibalulekile sekhwalithi yamashidi ensimbi ye-silicon. Wonke amazwe ahlukanisa amamaki ngokwenani lokulahlekelwa yinsimbi. Uma ukulahlekelwa yinsimbi kuphansi, kulapho izinga liphakama khona. ② Ukuqina kokungeniswa kwe-magnetic (ukungeniswa kwe-magnetic) kuphezulu ngaphansi kwensimu enamandla yamagnetic, okunciphisa ivolumu nesisindo sama-cores ama-motor nama-transformer, okusindisa amashidi ensimbi ye-silicon, izintambo zethusi, nezinto zokufaka umswakama. ③Ubuso bubushelelezi, buyisicaba futhi bufana ngobukhulu, okungathuthukisa isici sokugcwalisa senhliziyo. ④Izakhiwo ezinhle zokufaka umfutho zibaluleke kakhulu ekukhiqizeni ama-motor amancane namancane. ⑤Ifilimu yokufaka umfutho ebusweni inokunamathela okuhle kanye nokushibilika, ingavimbela ukugqwala futhi ithuthukise izakhiwo zokufaka umfutho.