Imikhiqizo

-

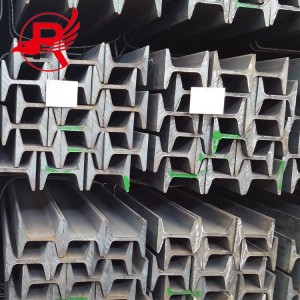

Ukusetshenziswa Kwezimayini Isitimela I-ISCOR Steel Rails Railway Crane Steel Rail Price

Izici eziyinhloko zesitimela sensimbi se-ISCOR zifaka phakathi amandla aphezulu, ukumelana nokuguguleka kanye nokuqina. Kudingeka zikwazi ukumelana nesisindo sezitimela kanye nokusetshenziswa njalo, ngakho-ke zidlala indima ebalulekile ekuthuthweni kwezitimela. Izitimela kudingeka zakhiwe futhi zikhiqizwe ngezindinganiso eziqinile ukuqinisekisa ikhwalithi nokuphepha kwazo.

-

Insimbi engu-41X21mm Unistrut C Channel Steel Post U Profile Steel

Amabhulakhethi e-Photovoltaicabizwa nangokuthi ama-solar photovoltaic brackets. Ama-solar photovoltaic brackets ayizibambo ezikhethekile ezenzelwe ukubeka, ukufaka nokulungisa amaphaneli elanga ezinhlelweni zokuphehla amandla e-solar photovoltaic Inkampani yethu ihlanganyele kuphrojekthi enkulu kunazo zonke yokuthuthukiswa kwamandla elanga eNingizimu Melika, ihlinzeka ngama-brackets kanye nomklamo wesisombululo. Sihlinzeke ngamathani ayi-15,000 ama-photovoltaic brackets alo msebenzi. Ama-photovoltaic brackets asebenzise ubuchwepheshe obusha basekhaya ukusiza ukuthuthukiswa kwemboni ye-photovoltaic eNingizimu Melika nokuthuthukisa izakhamuzi zendawo. Impilo. Iphrojekthi yokusekela i-photovoltaic ifaka isiteshi samandla se-photovoltaic esinomthamo ofakiwe ongaba ngu-6MW kanye nesiteshi samandla sokugcina amandla sebhethri esingu-5MW/2.5h. Singakhiqiza cishe amahora angu-1,200 kilowatt ngonyaka. Uhlelo lunamandla amahle okuguqula i-photoelectric.

-

Isevisi Yokukhiqiza Imikhiqizo Yehadiwe Eyenziwe Ngokwezifiso ye-Oem Ukwenziwa Kwensimbi Yeshidi Lensimbi

Izingxenye ezicutshungulwe ngensimbi, ezaziwa nangokuthi izingxenye zensimbi ezenziwe, zibhekisela ezingxenyeni noma emikhiqizweni eqediwe kancane eyenziwe ngezinto zokusetshenziswa zensimbi (njengezingqwembe zensimbi, amapayipi, kanye nezimo zesakhiwo) ngezinqubo ezifana nokusika, ukunyathela, ukugoba, ukushisela, ukwenza imishini, ukwelashwa kokushisa, kanye nokuqedwa kwendawo, ukuze kuhlangatshezwane nesimo esithile, usayizi, kanye nezidingo zokusebenza. Ngokuvamile zisetshenziswa njengezingxenye ezibalulekile zemishini, imishini, noma izakhiwo zobunjiniyela.

-

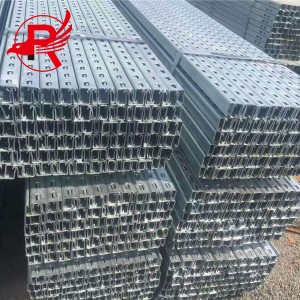

I-Factory Direct Supply Slotted Galvanized Strut Channel Steel Unistrut HDG Gi Strut C Channel Steel Prices

Uma wakhaizinhlelo ze-photovoltaicEzindaweni ezisogwini, zonke izingxenye zesakhiwo kufanele zenziwe ngensimbi ehlanganisiwe noma i-aluminium, njengoba lezi zinto zimelana kakhulu nokugqwala. Phakathi kwazo, ama-bracket e-aluminium alloy abe ngomunye wemikhiqizo ethandwayo emakethe yama-bracket e-photovoltaic ngenxa yesisindo sawo esilula, ukumelana nokugqwala, kanye nokufakwa okulula.

-

Osayizi Besiteshi Sensimbi 150X90 35355 Isiteshi Sokubumba Insimbi Egayiwe 41X41 Isiteshi Sensimbi Esingaphansi Kwe-Unistrut

Ibhulakhethi yokumiswa: Lolu hlobo lwebhulakhethi lumisa amaphaneli elanga ezintanjeni zocingo noma ezibhakeni eziphezulu esibhakabhakeni ukuze kutholakale ukukhanya kwelanga okukhulu.amabakaki e-photovoltaiczifanele izindawo zasemadolobheni njengezakhiwo zasemadolobheni namabhuloho, kanye nezindonga zangaphandle zezakhiwo, amapulatifomu nezinye izindawo. Zingalenga amamojula e-photovoltaic elanga ezindongeni zangaphandle zezakhiwo ngaphandle kokuthatha indawo yomhlabathi.

-

Isiteshi Sokubumba Insimbi Ehlanganisiwe 41X41 Unistrut Channel Steel

A i-photovoltaic bracketiyisakhiwo esisetshenziselwa ukufaka amaphaneli e-photovoltaic. Umsebenzi waso awukona nje ukulungisa amamojula e-photovoltaic phansi noma ophahleni, kodwa futhi nokulungisa i-engeli kanye nokuma kwamamojula e-photovoltaic ukuze kwandiswe ukusebenza kahle kwamandla elanga.

-

Umshini Wokusika I-Laser Die Umshini Wokusika I-Fiber Laser Ishidi Lensimbi

insimbi esikiwe nge-laserkuyindlela yokucubungula ukusika enembile kakhulu, esebenza kahle kakhulu esetshenziswa kabanzi ekucubungulweni kwezinsimbi, amapulasitiki, ukhuni nezinye izinto. Ukusika nge-laser kusebenzisa umsebe we-laser onamandla amakhulu ukuze kuncibilikiswe noma kushiswe izinto, okuvumela ukusika okusheshayo nokunembile. Le ndlela yokucubungula inezici ezilandelayo:

Okokuqala, ukusika nge-laser kunokunemba okuphezulu kakhulu kanye nobuncane, okuvumela ukusika nokuqopha izinto ezincane, futhi kufanelekile ukwenza izingxenye ezinezimo eziyinkimbinkimbi nezakhiwo ezinembile.

Okwesibili, ukusika nge-laser kuyashesha futhi kusebenza kahle kakhulu ekukhiqizeni. Imishini yokusika nge-laser ingahamba futhi isike ngokushesha, okwenza ifaneleke ekukhiqizeni ngobuningi obukhulu kanye nokucubungula okuphumelelayo.

Ngaphezu kwalokho, ukusika nge-laser akunawo umthelela omkhulu ezintweni futhi indawo ethintekile ekushiseni incane. Uma kuqhathaniswa nezindlela zokusika zendabuko, ukusika nge-laser kunganciphisa ukuguquguquka nemiphumela yokushisa futhi kugcine izakhiwo zokuqala zezinto.

Ukusika nge-laser kufaneleka ezintweni ezahlukahlukene, okuhlanganisa izinsimbi, ipulasitiki, ingilazi, izinto zobumba, njll., ngakho-ke kusetshenziswa kabanzi ezindizayo, ekukhiqizeni izimoto, emishinini kagesi nakwezinye izimboni.

Ngamafuphi, ukusika nge-laser, njengendlela yokucubungula ukusika enembile kakhulu futhi esebenza kahle kakhulu, kunikeza izixazululo zokucubungula ngokunemba kuzo zonke izigaba zokuphila futhi sekungenye yezinqubo ezibalulekile nezibalulekile ekukhiqizeni kwanamuhla.

-

Insizakalo Yokushisela Insimbi Yensimbi Eyenziwe Ngokwezifiso Nesevisi Yokusika I-Laser Izingxenye Zokunyathela Ukucutshungulwa Kwensimbi Yeshidi

Ukushisela kuyinqubo evamile yokukhiqiza esetshenziselwa ukuhlanganisa izinto zensimbi noma zepulasitiki ndawonye ngokuzincibilikisa, ukuziqinisa noma ukuzicindezela ndawonye. Izinqubo zokushisela zivame ukusetshenziswa ekwakhiweni kwezingxenye zesakhiwo, amapayipi, imikhumbi neminye imikhiqizo, kanye nasemsebenzini wokulungisa nokulungisa.

-

Ukusika i-Waterjet Okungahlukumezi Izingxenye Zokusika Insimbi Eziqondile Ngokwezifiso ze-OEM Insimbi Yekhabhoni Insimbi Engagqwali I-3/4/5 Axis CNC Machining

Ukusika i-Waterjet ubuchwepheshe obuthuthukisiwe bokusika okubandayo obusebenzisa umfudlana wamanzi ocindezela kakhulu (ngokuvamile ocindezelwe ube ngu-30,000–90,000 psi) — ngokuvamile kuxutshwe nezinhlayiya ezihuquzelayo njenge-garnet yezinto eziqinile — ukusika, ukuma, noma ukuqopha uhla olubanzi lwezinto zokusebenza. Njengenqubo ebandayo, igwema ukuphambuka kokushisa, ukuqina kwezinto, noma izinguquko zamakhemikhali ezintweni ezisikiwe, okwenza kube kuhle kakhulu ekusetshenzisweni okuzwela ukushisa noma okunembe kakhulu. Ibonisa ukuguquguquka okukhulu, ikwazi ukuphatha izinto ezifana nensimbi (insimbi, i-aluminium, i-titanium), itshe, ingilazi, izinto zobumba, izinto ezihlanganisiwe, ngisho nokudla, kanye nekhono lokusika izimo eziyinkimbinkimbi (isb., amaphethini ayinkimbinkimbi, imiphetho egobile) kanye nezinto zokusebenza ezijiyile (kufika kumashumi amasentimitha) ngenkathi igcina imiphetho ebushelelezi yokusika kanye nokunemba okuphezulu. Isetshenziswa kabanzi ezimbonini ezifaka phakathi izindiza (zezingxenye zensimbi ezinembile), izimoto (zezingxenye ezenziwe ngokwezifiso), izakhiwo (zezinto zokuhlobisa zamatshe/ingilazi), kanye nokukhiqiza (zokucubungula izinto ezihlanganisiwe), ukusika ijethi yamanzi nakho kuvelele ngobungane bayo bemvelo - ayikhiqizi umusi onobuthi noma imfucuza eningi, okuhambisana nezidingo zesimanje zokukhiqiza okuluhlaza.

-

Isiteshi se-Unistrut 41X41 SS304 SS316 Isiteshi se-U Strut esenziwe ngokwezifiso Insimbi Engagqwali

Ingaphezulu lensimbi yekhabhoni lifakwe nge-hot-dip galvanized. Ngeke ligqwale ngemva kweminyaka engama-30 lisetshenziswa ngaphandle. Izici zalo yilezi: akukho ukushisela, akukho ukubhoboza okudingekayo, okulungisekayo futhi okungasetshenziswa kabusha.insimbi yesiteshi se-cAma-rack alula ukuwahlanganisa nokuyifaka, angafakwa ngokushesha futhi anezindleko zokulungisa eziphansi. Ikakhulukazi, ama-bracket ensimbi e-c afakwe ohlakeni angasebenzisa isikhala sesakhiwo ngesikhathi sokufakwa ngaphandle kokuthatha indawo eyengeziwe, futhi abe nokuguquguquka okuphezulu kokufakwa.

-

Ukucubungula Insimbi Ukufa Kweshidi Lensimbi Ukushaya Nokwakha Inqubo Yokunyathela Ishidi Lensimbi

Izingxenye zethu zomshini ezisekelwe ensimbini zikhiqizwa kusetshenziswa izinto zokusetshenziswa zensimbi, ngokusekelwe emidwebweni yomkhiqizo enikezwe amakhasimende. Senza ngokwezifiso futhi sikhiqize amathuluzi okukhiqiza adingekayo ngokwezidingo ezithile zomkhiqizo oqediwe, kufaka phakathi ubukhulu, uhlobo lwezinto ezibonakalayo, kanye nanoma yikuphi ukwelashwa okukhethekile kwendawo. Sinikeza izinsizakalo zokukhiqiza ezinembile, zekhwalithi ephezulu, nezithuthukisiwe kwezobuchwepheshe ezenzelwe izidingo zamakhasimende. Ngisho noma ungenayo imidwebo yokuklama, abaklami bomkhiqizo wethu bangakha umklamo ngokusekelwe ezidingweni zakho.

-

Isiteshi Sokushisela, Ukusika Nge-Laser kanye ne-Plasma

Ukusika i-plasma ubuchwepheshe obuthuthukisiwe bokucubungula obusebenzisa izinga lokushisa eliphezulu namandla aphezulu akhiqizwa yi-plasma ukusika izinto. Enqubweni yokusika i-plasma, ingxube yegesi noma igesi ishiswa ibe yizinga lokushisa eliphezulu ukuze kukhiqizwe i-plasma, bese kusetshenziswa amandla aphezulu e-plasma ukusika izinto.

Ukusikwa kwe-plasma kunezici ezilandelayo: Okokuqala, kunezindlela eziningi zokusebenzisa futhi kungasika kahle izinto ezahlukahlukene njengezinsimbi, ama-alloy, insimbi engagqwali, kanye nama-alloy e-aluminium. Okwesibili, ijubane lokusika liyashesha futhi ukusebenza kahle kuphezulu, futhi kungafinyelela ukusika okunembile kwezinto ezinezimo ezahlukahlukene eziyinkimbinkimbi. Ngaphezu kwalokho, indawo ethintekile ekushiseni ekhiqizwa ngesikhathi sokusikwa kwe-plasma incane, indawo yokusikwa ibushelelezi, futhi akukho ukucutshungulwa kwesibili okudingekayo, okwenza ifanelekele izidingo zokucutshungulwa ngokunemba okuphezulu.

Ukusika i-plasma kusetshenziswa kabanzi ekucubungulweni kwensimbi, ekukhiqizweni kwemishini, ezindiza kanye neminye imikhakha. Emkhakheni wokucubungula insimbi, ukusika i-plasma kungasetshenziswa ukusika izingxenye zensimbi ezahlukahlukene, njengezingcwecwe zensimbi, izingxenye ze-aluminium alloy, njll., ukuqinisekisa ukunemba kanye nekhwalithi yezingxenye. Emkhakheni wezindiza, ukusika i-plasma kungasetshenziswa ukusika izingxenye zezindiza, njengezingxenye zenjini, izakhiwo ze-fuselage, njll., ukuqinisekisa ukunemba kanye nokukhanya kwezingxenye.

Ngamafuphi, ukusika i-plasma, njengobuchwepheshe bokucubungula ukusika obusebenza kahle futhi obunembile, kunamathuba amaningi okusetshenziswa kanye nesidingo semakethe, futhi kuzodlala indima ebalulekile embonini yokukhiqiza yesikhathi esizayo.