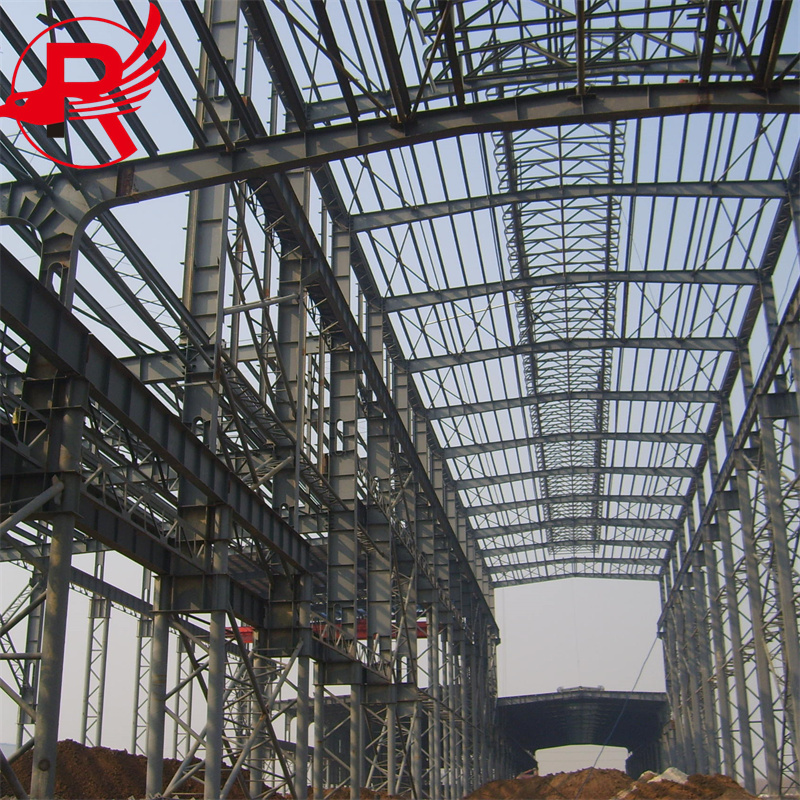

Indawo yokugcina izinto elungisiwe Isakhiwo Sensimbi Indawo Yokusebenzela Isakhiwo Sensimbi Yezimboni Indawo yokugcina izinto elungisiwe

I-prefabricaisakhiwo sensimbi esihlanganisiweisakhiwo sensimbi esakhiwe ngezinto zensimbi futhi singenye yezinhlobo eziyinhloko zesakhiwo sesakhiwo. Isakhiwo sakhiwe kakhulu ngesakhiwo sensimbi, amakholomu ensimbi, ama-trusses ensimbi nezinye izingxenye ezenziwe ngensimbi yesigaba namapuleti ensimbi, futhi samukela i-silanization, i-phosphating ye-manganese emsulwa, ukuwasha nokomisa, i-galvanizing kanye nezinye izinqubo zokuvimbela ukugqwala.

*Kuye ngesicelo sakho, singaklama uhlelo lohlaka lwensimbi olungabizi kakhulu noluhlala isikhathi eside ukukusiza ukuthi udale inani eliphezulu lephrojekthi yakho.

| Igama lomkhiqizo: | Isakhiwo Sensimbi Isakhiwo Sensimbi |

| Izinto: | Q235B ,Q345B |

| Uhlaka oluyinhloko: | Umshayo wensimbi omise okwe-H |

| I-Purlin: | C,Z - insimbi enemibala ye-purlin |

| Uphahla nodonga: | 1. ishidi lensimbi eligoqiwe; 2. amaphaneli esandwich oboya bedwala; 3. Amaphaneli esandwich e-EPS; Amaphaneli esandwich kawoyela ayi-4.ingilazi |

| Umnyango: | 1. Isango lokugingqika 2. Umnyango oshelelayo |

| Ifasitela: | Insimbi ye-PVC noma i-aluminium alloy |

| Umbhobho ophansi: | Ipayipi le-PVC eliyindilinga |

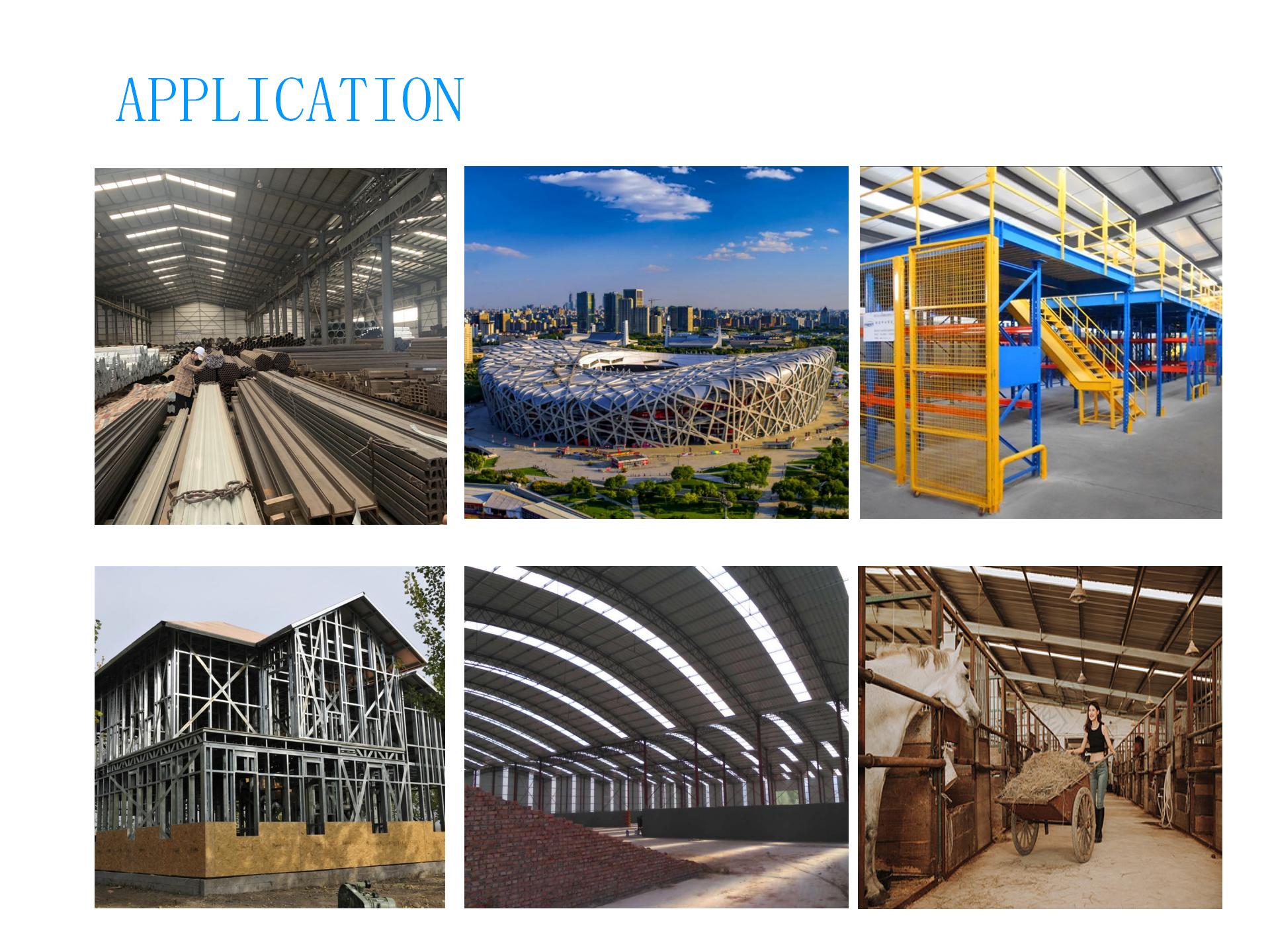

| Isicelo: | Zonke izinhlobo zezindawo zokusebenzela zezimboni, indawo yokugcina impahla, isakhiwo esinezitezi eziphakeme |

INQUBO YOKUKHIQIZWA KOMKHIQIZO

INZUZO

Ukwembula Izinzuzo Zezakhiwo Zensimbi Ekwakhiweni

Esimweni sokwakha sesimanje esishintsha njalo, izakhiwo zensimbi sezibe amandla amakhulu, zinikeza izinzuzo eziningi ezihlangabezana nezidingo eziningi zephrojekthi. Lezi zinzuzo zibonakala kakhulu kosonkontileka bezakhiwo zensimbi, osonkontileka bezakhiwo zensimbi, abakhi bezindawo zokugcina izimpahla zensimbi, izikole zensimbi, kanye namahhotela ensimbi.

Amandla Aphakeme Nokuqina

Insimbi, eyaziwa ngesilinganiso sayo esiphakeme samandla nesisindo, iyinsika yezakhiwo eziqinile nezihlala isikhathi eside.Izinkontileka zokwakha insimbingokuvamile bathanda insimbi ngoba ingamelana nemithwalo emikhulu, kungakhathaliseki ukuthi imishini esindayoisitoreji sesakhiwo sensimbinoma amandla ashukumisayo isikole sensimbi esibhekana nawo ngesikhathi sokuzamazama komhlaba. Izakhiwo zensimbi zingamelana nezimo zezulu ezinzima, okuhlanganisa imimoya enamandla, iqhwa elinamandla, kanye nemvula enkulu. Kumahhotela ensimbi atholakala ezindaweni ezisogwini noma ezindaweni ezivame ukuba nesimo sezulu esibi kakhulu, lokhu kuqina kuqinisekisa ukuphepha kwezivakashi futhi kugcina ubuqotho besakhiwo isikhathi eside, kunciphisa izindleko zokulungisa nokulungisa zesikhathi eside.

Inqubo Yokwakha Esheshayo

Isikhathi sibaluleke kakhulu embonini yokwakha, futhi izakhiwo zensimbi ziyaphumelela kulokhu. Abakhi bezinsimbi bangakha izingxenye zensimbi ngokunemba okuphezulu efektri. Lezi zingxenye ezilungisiwe zibe sezithuthwa ziyiswe endaweni yokwakha ukuze zihlanganiswe ngokushesha. Kwabakhi bezindawo zokugcina izimpahla zensimbi, lokhu kusho ukuthi izikhathi zokwakha zifushane kakhulu uma kuqhathaniswa nezindlela zokwakha zendabuko. Ezikoleni noma emahhotela ensimbi, lesi sikhathi sokwakha esifushane sivumela abantu ukuthi bahlale khona kusenesikhathi, okuvumela abafundi ukuthi baqale izifundo zabo noma izivakashi ukuthi zithuthele kusenesikhathi, okwandisa inzuzo ekutshalweni kwezimali.

Ukuguquguquka Kwedizayini Nokuzivumelanisa Nezimo

Izakhiwo zensimbi zinikeza abakhi bezakhiwo nabaklami ukuguquguquka okungenakuqhathaniswa. Ngesikhathi sokwakhiwa kwezakhiwo zensimbi, izikhala ezinkulu, ezingenamakholomu zingatholakala kalula, okuvumela ukuguquguquka kwezakhiwo zangaphakathi. Lokhu kuzuzisa kakhulu amahhotela ensimbi, okuvumela izindawo zokuphumula ezivulekile, amahholo amakhulu edili, noma izindawo zokuhlangana eziguquguqukayo ezenzelwe izidingo zezivakashi. Ezikoleni zensimbi, amakilasi abanzi, amakamelo anezinhloso eziningi, nezindawo zokufunda ezivulekile zingaklanywa ngaphandle kwamakholomu amaningi, okwakha indawo yokufunda enhle kakhulu. Abakhi bezinsimbi bangasebenzisana eduze nabaklami ukuze balethe ngisho nemiklamo eyinkimbinkimbi kakhulu futhi emisha ekuphileni, beyivumelanisa nezidingo ezithile zephrojekthi ngayinye.

Ukusimama kanye nokuvikelwa kwemvelo

Esikhathini sokuqwashisa ngemvelo okukhula, izakhiwo zensimbi zivelele njengenketho eqhubekayo. Insimbi ingenye yezinto eziphinde zisetshenziswe kakhulu emhlabeni. Kungakhathaliseki ukuthi iyindlu yokugcina insimbi, isikole, noma ihhotela, ekupheleni komjikelezo wokuphila kwesakhiwo sensimbi, izingxenye zayo zensimbi zingaphinde zisetshenziswe futhi, kuncishiswe isidingo sezinto zokusetshenziswa futhi kuncishiswe imfucuza ethunyelwa ezindaweni zokulahla udoti.Izikole zesakhiwo sensimbifuthiAmahhotela esakhiwo sensimbiingaphinde ifake imiklamo eyonga amandla, njengokushisa okufanele, ukuze kwehliswe izindleko zokushisa nokupholisa. Izinkontileka zokwakha insimbi ziya ngokuya zamukela imikhuba yokwakha esimeme, futhi izakhiwo zensimbi zihambisana kahle nale migomo, okwenza kube ukukhetha okunobungani nemvelo kunoma yimuphi umsebenzi wokwakha.

Izinzuzo Zezindleko Zesikhathi Eside

Nakuba izindleko zokuqala zensimbi zingase zibonakale ziphakeme, ukuhlaziywa okujulile kwembula izinzuzo zayo zezindleko zesikhathi eside. Ukwakhiwa kwensimbi kuthatha isikhathi esincane ukwakha, kunciphisa izindleko zabasebenzi kanye nobude bephrojekthi iyonke. Kwabakhi bezindawo zokugcina izimpahla zensimbi, lokhu kusho ukulungela ukusebenza okusheshayo kanye nokukhiqizwa kwemali engenayo kusenesikhathi. Ukuqina kwensimbi kunciphisa nezindleko zokulungisa, okuholela ezindleleni zokulungisa eziphansi zesikhathi eside. Ezikoleni zensimbi namahhotela, impilo yesevisi ende kanye nesidingo esinciphile sokulungisa kusho ukonga okukhulu kwezindleko zesikhathi eside. Abakhi bezakhiwo zensimbi bangasebenzisa izinzuzo zokwakha insimbi ukuze banikeze amakhasimende izixazululo ezingabizi kakhulu eziletha inani lemali ngaphandle kokubeka engcupheni ikhwalithi.

Ngamafuphi, izakhiwo zensimbi zinikeza amandla, ukuqina, ukuguquguquka komklamo, ukusimama, kanye nokusebenza kahle kwezindleko. Kungakhathaliseki ukuthi ubuchwepheshe bezinkontileka zokwakha insimbi ekwakheni izakhiwo zensimbi, izidingo zokusebenza zabakhi bezindawo zokugcina izimpahla zensimbi, noma izidingo ezithile zezikole namahhotela ensimbi, izakhiwo zensimbi ziye zabonakala ziyisinqumo esifanele embonini yokwakha, zibeka amazinga amasha amaphrojekthi okwakha esimanje.

IMINININGWANE YOMKHIQIZO

Ukwakhiwa kweUmklamo Wesakhiwo SensimbiIzakhiwo zefektri zihlukaniswe kakhulu izingxenye ezinhlanu ezilandelayo:

1. Izingxenye ezifakiwe (ukuze kuqiniswe isakhiwo sefektri)

2. Amakholomu ngokuvamile akhiwa ngensimbi enobunjwa obungu-H noma insimbi enobunjwa obungu-C (ngokuvamile izinsimbi ezimbili ezinobunjwa obungu-C zixhunywe nensimbi ekhoneni).

3. Imishayo ngokuvamile yakhiwa ngensimbi enobunjwa obungu-C kanye nensimbi enobunjwa obungu-H (ukuphakama okuphakathi kunqunywa ubude bemishayo).

4. Ama-purlin ensimbi: Ngokuvamile akhiwe ngensimbi enobunjwa obungu-C kanye nensimbi enobunjwa obungu-Z.

5. Izindawo zokusekela kanye nezinduku zokucindezela ngokuvamile zakhiwe ngensimbi eyindilinga.

6. Kunezinhlobo ezimbili zamathayela ophahla. Elokuqala ngamathayela ophahla anethayela (ophahla lwensimbi olunombala). Elesibili ngamaphaneli esandwich (amashidi ensimbi anombala ophindwe kabili ahlanganiswe ngamaphaneli e-polyurethane noma e-rock wool). Lawa ahlinzeka ngokufudumala ebusika kanye nokuphola ehlobo, kuyilapho futhi ehlinzeka ngokuvikela umsindo kanye nokumelana nomlilo.

Isicelo

Izakhiwo zezimboni:Ikesi lesakhiwo sensimbizivame ukusetshenziswa emafektri noma ezindaweni zokugcina impahla. Imodyuli elungiselelwe kusengaphambili, kanye nokucubungula, ukukhiqiza, ukuthuthwa kanye nokufakwa kuyashesha kakhulu. Ngaphezu kwalokho, ilula ngesisindo futhi inomthamo oqinile wokuthwala kanye nokumelana nokushaqeka, okungaqinisekisa ukuphepha nokuzinza kwesitshalo. Ngaphezu kwalokho, isakhiwo sensimbi singahlakazwa futhi sakhiwe kabusha ngokwezidingo, ngokuguquguquka okunamandla.

Izakhiwo zezolimo: Zifanelekela izinhlobo ezahlukene zezitshalo zezolimo nezemifino, zinikeza izinzuzo ezifana nokudlulisa ukukhanya okuphezulu, ukusebenza kahle kokushisa okuphezulu, ukonga amandla, ukuvikelwa kwemvelo, kanye nezindleko zokusebenza eziphansi. Isakhiwo sazo sokusekela uhlaka lwensimbi yonke kanye nomklamo ongenamakholomu kwenza i-greenhouse ithwale umthwalo kakhudlwana, izinzile, futhi ithembeke, futhi ifanelekele ukufuya izilwane.

Izakhiwo zomphakathi: Izakhiwo eziningi eziphakeme nezinkundla zemidlalo okwamanje zisebenzisa izakhiwo zensimbi, ezizivikela ngempumelelo ezinhlekeleleni zemvelo njengokuzamazama komhlaba nemililo, kanye nomonakalo wabantu. Izakhiwo zensimbi azikwazi ukugqwala, azikwazi ukushisa, futhi azikwazi ukumelana nomlilo, okwenza kube lula ukuzinakekela. Izakhiwo zensimbi ngokuvamile zakhiwa ngezinto ezinamandla aphezulu, futhi insimbi ngokwayo ayidingi imishini yokucubungula, ngaleyo ndlela isindisa utshalomali olukhulu.

Izakhiwo zokuhlala: Izici zezakhiwo zensimbi zizenza zibe lula futhi zibonakale, okuvumela ukufezwa kwemiklamo yendawo emikhulu kanye nemiklamo eyinkimbinkimbi, yokudala ngezindleko eziphansi, ukongiwa kwamandla, kanye nokuvikelwa kwemvelo.

Amapulatifomu emishini: Izinto zokusetshenziswa ezisetshenziselwa amapulatifomu ensimbi zibonisa ukuguqulwa kwepulasitiki okuhle kakhulu kanye nokuguquguquka, okuvumela ukuguqulwa okukhulu kanye nokumelana okuhle kakhulu nemithwalo yokushayela, ukunciphisa amashejuli okwakha kanye nokonga isikhathi kanye namandla abasebenzi. Imishini yobunjiniyela besakhiwo sensimbi inezinga eliphezulu lokuzenzakalela, ingenza ukukhiqiza okuhlelekile kanye nokukhiqiza, ithuthukise ukusebenza kahle komsebenzi, inciphise ubunzima be-coefficient yokwakha ubunjiniyela, futhi ihambisana nezici zamanje zokusebenza okusheshayo kanye nentuthuko yomphakathi enobungani nemvelo.

UKUHLOLWA KOMKHIQIZO

Ngaphambi kokuthunyelwaisakhiwo sensimbiimikhiqizo, izingxenye kumele zihlolwe ukuqinisekisa ukuthi ikhwalithi yomkhiqizo iphelele. Izingxenye zensimbi kufanele zihlolwe usayizi, ukuma, ikhwalithi yobuso, njll. Izingxenye ezonakele noma ezingahambisani nengxenye kufanele zishintshwe noma zilungiswe ngesikhathi esifanele. Ukuhlolwa kwekhwalithi yamaphrojekthi esakhiwo sensimbi kufaka phakathi konke okuqukethwe kokuhlolwa nokuhlolwa kwezinto zokusetshenziswa, izinto zokushisela, ama-weldment, ama-fasteners, ama-welds, ama-bolt ball joints, ama-coating nezinye izinto kanye namaphrojekthi ezakhiwo zensimbi. Ukuhlolwa kokuthatha amasampula, ukuhlaziywa kokwakheka kwamakhemikhali ensimbi, ukuhlolwa kopende kanye nokumbozwa komlilo.

IPHROJEKTHI

Inkampani yethu ibambisene nabaningiinkampani yesakhiwo sensimbiamaphrojekthi okwakha eMelika, eNingizimu-mpumalanga ye-Asia nakwamanye amazwe.

Isakhiwo sefektri yesakhiwo sensimbi sihlanganisa indawo engaba amamitha-skwele angama-50,000.

Isakhiwo sefektri sesakhiwo sensimbi sakhiwe ngokuyinhloko isisekelo, izinsika zensimbi, imishayo yensimbi, uphahla, kanye nezindonga.

Isisekelo: Izingxenye zesisekelo ezifakiwe ziyingxenye ebalulekile yesakhiwo sefektri, ikakhulukazi ezibhekene nokudlulisa isisindo sesakhiwo sefektri phansi nokuqinisekisa ukuqina kwaso.

Amakholomu ensimbi: Amakholomu ensimbi ayizingxenye eziyinhloko ezithwala umthwalo wesakhiwo sefektri futhi kumele athwale isisindo sonke. Ngakho-ke, kumele abe namandla nokuqina okwanele.

Imishayo yensimbi: Imishayo yensimbi nayo ingenye yezingxenye eziyinhloko ezithwala imithwalo yesakhiwo sefektri, yabelana ngesisindo sesakhiwo sefektri nezinsika zensimbi.

Uphahla: Uphahla luyingxenye ebalulekile yesakhiwo sefektri futhi kumele luhlinzeke ngokuvikela amanzi, ukuvikela ukushisa, kanye nokuvikela ukushisa. Ngokuvamile lwakhiwe ngamapuleti ensimbi anombala, ama-purlin, kanye nezisekelo.

Izindonga: Esinye isici esibalulekile sesakhiwo sefektri, izindonga kumele zihlinzeke ngokuvikela umswakama, ukuvimbela umsindo, kanye nokuvikela amanzi. Ngokuvamile zakhiwe ngamaphaneli odonga, izinto zokuvikela umswakama, kanye nezisekelo.

UKUPHAKISHA NOKUTHUMELA

Ukupakisha: Ngokwezidingo zakho noma ezifanele kakhulu.

Ukuthunyelwa:

Khetha indlela yokuthutha efanele: Ngokusekelwe enanini kanye nesisindo sezakhiwo zensimbi, khetha indlela yokuthutha efanele, njengeloli eliyisicaba, isitsha, noma umkhumbi. Cabangela izici ezifana nebanga, isikhathi, izindleko, kanye nanoma yimiphi imithethonqubo yokuthutha efanele ngesikhathi sokuthutha.

Sebenzisa imishini yokuphakamisa efanele: Uma ulayisha futhi uthulula izakhiwo zensimbi, sebenzisa imishini yokuphakamisa efanele, njenge-crane, i-forklift, noma i-loader. Qinisekisa ukuthi imishini inamandla anele okuphatha ngokuphephile isisindo sezinqwaba zeshidi lensimbi.

Vikela umthwalo: Vikela inqwaba yesakhiwo sensimbi epakishiwe emotweni yokuthutha usebenzisa izintambo, izinsimbi zokubopha, noma ezinye izindlela ezifanele zokuvimbela ukugudluka, ukushelela, noma ukuwa ngesikhathi sokuthutha.

AMANDLA ENKAMPANI

Kwenziwe eShayina, isevisi yekilasi eliphezulu, ikhwalithi ephezulu, idumile emhlabeni jikelele

1. Umphumela Wesilinganiso: Inkampani yethu inochungechunge olukhulu lokuhlinzeka kanye nefektri enkulu yensimbi, efinyelela imiphumela emikhulu kwezokuthutha kanye nokuthengwa kwempahla, futhi iba yinkampani yensimbi ehlanganisa ukukhiqiza kanye nezinsizakalo.

2. Ukwehlukahluka komkhiqizo: Ukwehlukahluka komkhiqizo, noma iyiphi insimbi oyifunayo ingathengwa kithi, ikakhulukazi ehilelekile esakhiweni sensimbi, izinsimbi zensimbi, izinqwaba zeshidi lensimbi, amabhulakhethi e-photovoltaic, insimbi yesiteshi, amakhoyili ensimbi ye-silicon neminye imikhiqizo, okwenza kube lula ukukhetha uhlobo lomkhiqizo olufunayo ukuze luhlangabezane nezidingo ezahlukene.

3. Ukunikezwa okuzinzile: Ukuba nomugqa wokukhiqiza ozinzile kanye nochungechunge lokunikezwa kunganikeza ukunikezwa okuthembekile. Lokhu kubaluleke kakhulu kubathengi abadinga insimbi eningi.

4. Ithonya lomkhiqizo: Linethonya lomkhiqizo eliphezulu kanye nemakethe enkulu

5. Isevisi: Inkampani enkulu yensimbi ehlanganisa ukwenza ngokwezifiso, ezokuthutha kanye nokukhiqiza

6. Ukuncintisana kwentengo: intengo enengqondo

*Thumela i-imeyili ku-[i-imeyili ivikelwe]ukuthola ikhotheshini yamaphrojekthi akho

UKUVAKASHELA KWAMAKHASIMENDE