Ukucutshungulwa Kwensimbi Nokwenziwe Ngokwezifiso

-

Izitebhisi Ezijikelezayo Zangaphandle Zesimanje Zomklamo Wezitebhisi Zensimbi Zensimbi Zangaphandle

Izitebhisi zangaphandle ezijikelezayo zanamuhla ziwuhlobo lwezitebhisi ezonga isikhala, zesimanje futhi ezisebenzayo ezijikelezayo phezulu zizungeze ikholomu ephakathi. Zingasetshenziswa ema-terrace, ema-deck, kuma-balcony, engadini, noma njengesixhumanisi sangaphandle phakathi kwezikhala emazingeni ahlukahlukene.

-

Izingxenye ze-ASTM Standard Welded H-Beam Structural Steel Fabrication for Construction & Steel Structures

Izingxenye ze-H-Beam ziyimikhiqizo yensimbi ye-H-beam ecutshungulwa ngokusika, ukushisela, ukubhoboza, ukwelashwa kwendawo nokunye. Zisetshenziswa kakhulu esakhiweni sensimbi, esitshalweni sezimboni, eshabhu, endaweni yokugcina impahla, ebhulohweni kanye nengqalasizinda enomthwalo omkhulu kanye nokuqina kwesakhiwo.

-

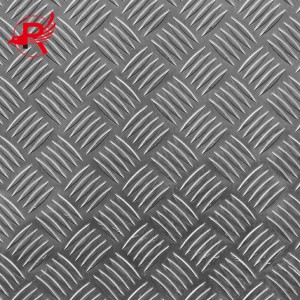

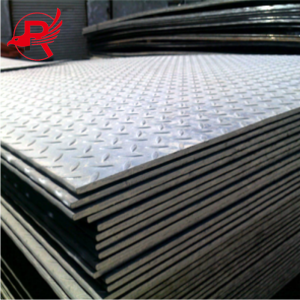

Ipuleti Elibunjiwe le-ASTM A36 1008 4320 SS400 S235JR Eligoqiwe Elishisayo Lensimbi Yekhabhoni ye-MS Enezinhlayiya Ezinezinhlayiya/Ishidi Ledayimane

Amapuleti ensimbi aqinile anezingqimba anamaphethini aphakanyisiwe ukuze abambe kahle—afanelekela kahle phansi kwezimboni, izindlela zokuhamba ngezinyawo, kanye nezitebhisi.

-

Ipuleti Lensimbi Enezinhlayiya Ezinezinhlayiya Ezinekhwalithi Ephezulu Ethengiswa Ngokushisayo Esezingeni Eliphezulu Lokuthumela Ngaphandle

Amapuleti ensimbi aqinile anezingqimba anamaphethini angasheleli—afanelekela kahle phansi kwezimboni, izindlela zokuhamba ngezinyawo, kanye nezitebhisi.

-

Ipuleti Lensimbi Yekhabhoni le-Astm A36 A252 Ipuleti Lensimbi Enezinhlayiya ze-Q235

Insimbi yepuleti ledayimane uhlobo lweshidi lensimbi elinedayimane eliphakanyisiwe noma iphethini eqondile ebusweni balo, elenzelwe ukuthuthukisa ukubamba nokubamba. Livame ukusetshenziswa phansi kwezimboni, izindlela zokuhamba, izitebhisi, nezinye izinhlelo zokusebenza lapho ukumelana nokushelela kubalulekile khona. Lawa mapuleti ensimbi atholakala ngobukhulu obuhlukahlukene nobukhulu, angenziwa ngensimbi yekhabhoni, insimbi engagqwali, noma ezinye izinsimbi, enikeza ukuguquguquka nokuqina ezindaweni eziningi zezimboni nezentengiselwano.

-

Ipuleti Lensimbi Yekhabhoni Eliphezulu Lekhwalithi Ephakeme Lefektri Eligoqiwe Elishisayo Elinezinhlayiya Ezi ...

Amapuleti ensimbi anezinhlayiya, aziwa nangokuthi amapuleti ensimbi anezinhlayiya noma amapuleti ensimbi angasheleli, angamashidi ensimbi anephethini ephakanyisiwe ebusweni bawo. Amaphethini avamile afaka phakathi ukuma kwedayimane, okungunxande, nokuyindilinga. Lawa maphethini awagcini nje ngokuthuthukisa izakhiwo ezingasheleli zepuleti lensimbi, kodwa futhi ahlinzeka ngobuhle obuhle kanye namandla akhuphukile. Amapuleti ensimbi anjalo asetshenziswa kabanzi emapulatifomu ezimboni, ezitebhisini, ezindleleni zokuhamba ngezinyawo, ezitezi zezimoto, ezitezi zokugcina impahla, nakwezinye izindawo, okunikeza kokubili ukuphepha nokuqina.

-

Ipuleti Lensimbi Eline-Chequered Steel 4 Mm Lensimbi Yekhabhoni Eyenziwe Ngensimbi Yekhabhoni Yezinto Zokwakha

Amapuleti ensimbi anezinhlayiya, aziwa nangokuthi amapuleti ensimbi anezinhlayiya noma amapuleti ensimbi angasheleli, angamashidi ensimbi anephethini evamile yezinsika eziphakanyisiwe ebusweni bawo. Amaphethini avamile afaka phakathi ukuma kwedayimane, okusaqanda, kanye nokuyindilinga. Lesi sakhiwo sobuso esiyingqayizivele asigcini nje ngokuthuthukisa ukungqubuzana futhi sivimbele ukushelela, kodwa futhi sinikeza ukubukeka okuhle okuthile.

-

Ukwakhiwa Kwesakhiwo Sepuleti Elinongwengwezi I-ASTM A36 Q235B Q345B S235JR S355JR Amapuleti Ensimbi Ashisayo Agoqekile

Amapuleti ensimbi anezinhlayiya, aziwa nangokuthi amapuleti edayimane noma amapuleti okunyathela, ayimikhiqizo yensimbi ekhethekile eklanywe ngamaphethini aphezulu obuso—ikakhulukazi amadayimane noma okwakheka okuqondile—adalwe ngokugoqa okushisayo, ukunyathela okubandayo, noma ukunamathisela. Inzuzo yawo eyinhloko itholakala ekusebenzeni okungasheleli kwalezi zindwangu eziphakeme: ngokwandisa ukungqubuzana kobuso, anciphisa ngempumelelo izingozi zokushelela ngisho nasezimweni ezimanzi, ezinamafutha, noma ezinothuli, okwenza kube ukukhetha okugxile ekuphepheni kwezimo ezinabantu abaningi noma ezinzima.

-

Isevisi Yokukhiqiza Imikhiqizo Yehadiwe Eyenziwe Ngokwezifiso ye-Oem Ukwenziwa Kwensimbi Yeshidi Lensimbi

Izingxenye ezicutshungulwe ngensimbi, ezaziwa nangokuthi izingxenye zensimbi ezenziwe, zibhekisela ezingxenyeni noma emikhiqizweni eqediwe kancane eyenziwe ngezinto zokusetshenziswa zensimbi (njengezingqwembe zensimbi, amapayipi, kanye nezimo zesakhiwo) ngezinqubo ezifana nokusika, ukunyathela, ukugoba, ukushisela, ukwenza imishini, ukwelashwa kokushisa, kanye nokuqedwa kwendawo, ukuze kuhlangatshezwane nesimo esithile, usayizi, kanye nezidingo zokusebenza. Ngokuvamile zisetshenziswa njengezingxenye ezibalulekile zemishini, imishini, noma izakhiwo zobunjiniyela.

-

Umshini Wokusika I-Laser Die Umshini Wokusika I-Fiber Laser Ishidi Lensimbi

insimbi esikiwe nge-laserkuyindlela yokucubungula ukusika enembile kakhulu, esebenza kahle kakhulu esetshenziswa kabanzi ekucubungulweni kwezinsimbi, amapulasitiki, ukhuni nezinye izinto. Ukusika nge-laser kusebenzisa umsebe we-laser onamandla amakhulu ukuze kuncibilikiswe noma kushiswe izinto, okuvumela ukusika okusheshayo nokunembile. Le ndlela yokucubungula inezici ezilandelayo:

Okokuqala, ukusika nge-laser kunokunemba okuphezulu kakhulu kanye nobuncane, okuvumela ukusika nokuqopha izinto ezincane, futhi kufanelekile ukwenza izingxenye ezinezimo eziyinkimbinkimbi nezakhiwo ezinembile.

Okwesibili, ukusika nge-laser kuyashesha futhi kusebenza kahle kakhulu ekukhiqizeni. Imishini yokusika nge-laser ingahamba futhi isike ngokushesha, okwenza ifaneleke ekukhiqizeni ngobuningi obukhulu kanye nokucubungula okuphumelelayo.

Ngaphezu kwalokho, ukusika nge-laser akunawo umthelela omkhulu ezintweni futhi indawo ethintekile ekushiseni incane. Uma kuqhathaniswa nezindlela zokusika zendabuko, ukusika nge-laser kunganciphisa ukuguquguquka nemiphumela yokushisa futhi kugcine izakhiwo zokuqala zezinto.

Ukusika nge-laser kufaneleka ezintweni ezahlukahlukene, okuhlanganisa izinsimbi, ipulasitiki, ingilazi, izinto zobumba, njll., ngakho-ke kusetshenziswa kabanzi ezindizayo, ekukhiqizeni izimoto, emishinini kagesi nakwezinye izimboni.

Ngamafuphi, ukusika nge-laser, njengendlela yokucubungula ukusika enembile kakhulu futhi esebenza kahle kakhulu, kunikeza izixazululo zokucubungula ngokunemba kuzo zonke izigaba zokuphila futhi sekungenye yezinqubo ezibalulekile nezibalulekile ekukhiqizeni kwanamuhla.

-

Insizakalo Yokushisela Insimbi Yensimbi Eyenziwe Ngokwezifiso Nesevisi Yokusika I-Laser Izingxenye Zokunyathela Ukucutshungulwa Kwensimbi Yeshidi

Ukushisela kuyinqubo evamile yokukhiqiza esetshenziselwa ukuhlanganisa izinto zensimbi noma zepulasitiki ndawonye ngokuzincibilikisa, ukuziqinisa noma ukuzicindezela ndawonye. Izinqubo zokushisela zivame ukusetshenziswa ekwakhiweni kwezingxenye zesakhiwo, amapayipi, imikhumbi neminye imikhiqizo, kanye nasemsebenzini wokulungisa nokulungisa.

-

Ukusika i-Waterjet Okungahlukumezi Izingxenye Zokusika Insimbi Eziqondile Ngokwezifiso ze-OEM Insimbi Yekhabhoni Insimbi Engagqwali I-3/4/5 Axis CNC Machining

Ukusika i-Waterjet ubuchwepheshe obuthuthukisiwe bokusika okubandayo obusebenzisa umfudlana wamanzi ocindezela kakhulu (ngokuvamile ocindezelwe ube ngu-30,000–90,000 psi) — ngokuvamile kuxutshwe nezinhlayiya ezihuquzelayo njenge-garnet yezinto eziqinile — ukusika, ukuma, noma ukuqopha uhla olubanzi lwezinto zokusebenza. Njengenqubo ebandayo, igwema ukuphambuka kokushisa, ukuqina kwezinto, noma izinguquko zamakhemikhali ezintweni ezisikiwe, okwenza kube kuhle kakhulu ekusetshenzisweni okuzwela ukushisa noma okunembe kakhulu. Ibonisa ukuguquguquka okukhulu, ikwazi ukuphatha izinto ezifana nensimbi (insimbi, i-aluminium, i-titanium), itshe, ingilazi, izinto zobumba, izinto ezihlanganisiwe, ngisho nokudla, kanye nekhono lokusika izimo eziyinkimbinkimbi (isb., amaphethini ayinkimbinkimbi, imiphetho egobile) kanye nezinto zokusebenza ezijiyile (kufika kumashumi amasentimitha) ngenkathi igcina imiphetho ebushelelezi yokusika kanye nokunemba okuphezulu. Isetshenziswa kabanzi ezimbonini ezifaka phakathi izindiza (zezingxenye zensimbi ezinembile), izimoto (zezingxenye ezenziwe ngokwezifiso), izakhiwo (zezinto zokuhlobisa zamatshe/ingilazi), kanye nokukhiqiza (zokucubungula izinto ezihlanganisiwe), ukusika ijethi yamanzi nakho kuvelele ngobungane bayo bemvelo - ayikhiqizi umusi onobuthi noma imfucuza eningi, okuhambisana nezidingo zesimanje zokukhiqiza okuluhlaza.