Isitimela Sensimbi Se-ISCOR Sezinga Eliphezulu Sezimboni Zokumbiwa Kwezitimela Sensimbi Esingu-9kg

IIsitimela sensimbi se-ISCORemzileni kuxhunywe ndawonye kusetshenziswa i-plywood nama-bolts, abizwa ngokuthi ama-rail joints. Umphumela oguquguqukayo we-wheel-rail e-joint mkhulu, kanti umsebenzi wokulungisa nokulungisa unzima. I-joint ingenye yezixhumanisi ezibuthakathaka zesakhiwo se-track.

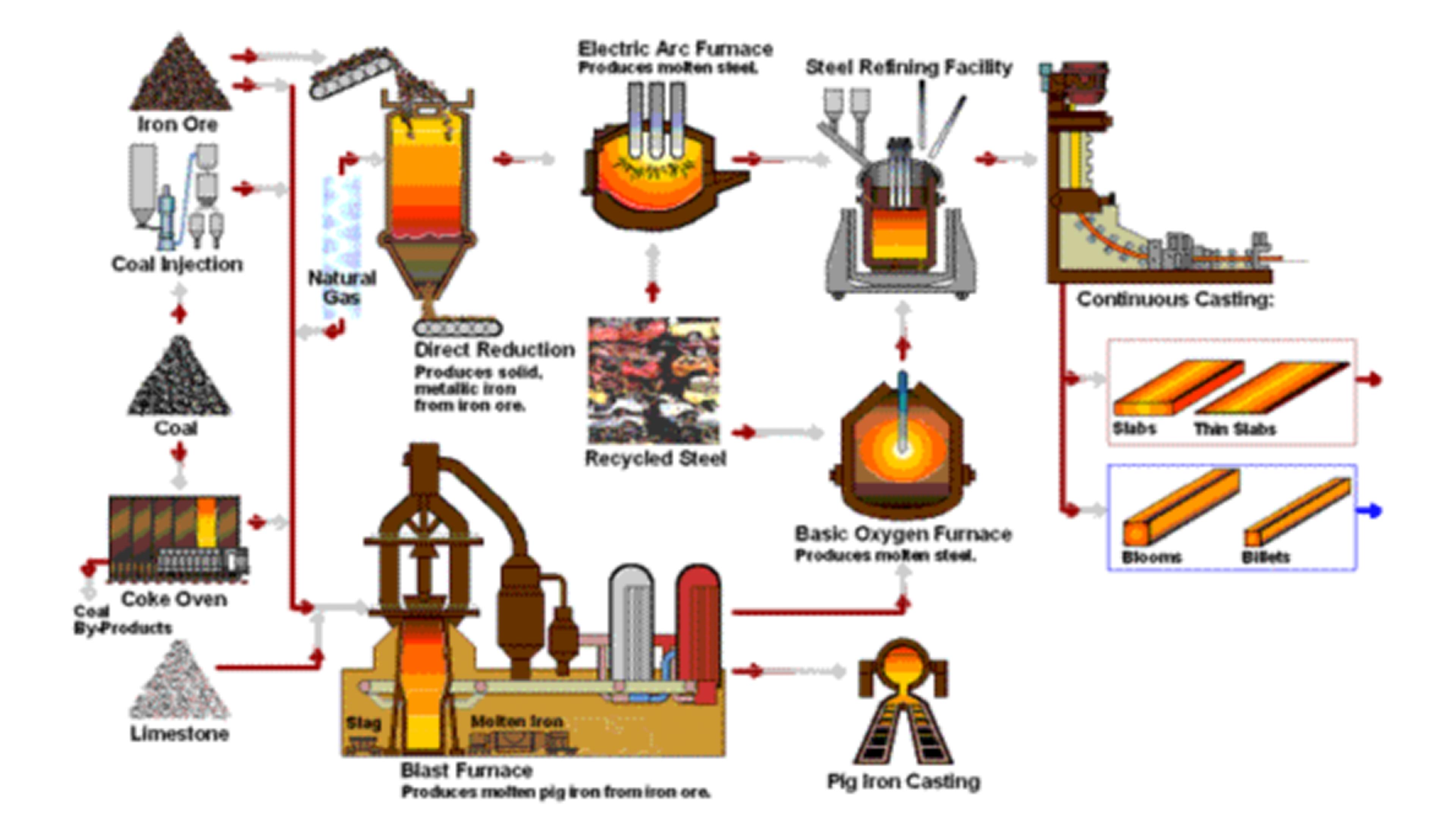

INQUBO YOKUKHIQIZWA KOMKHIQIZO

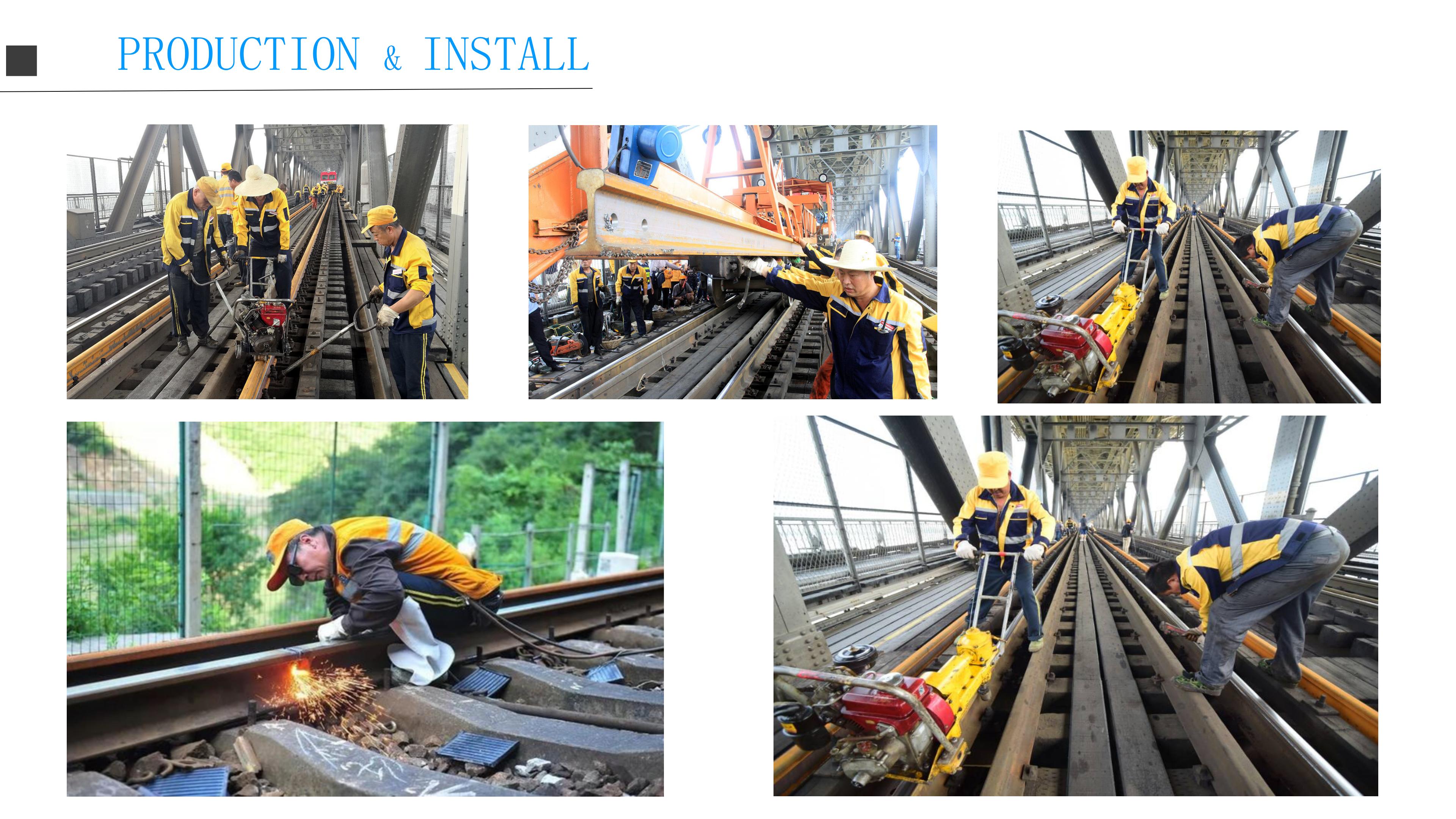

Ubuchwepheshe kanye nenqubo yokwakha

Inqubo yokwakhaisitimela sesitimelaimizila ihilela ubunjiniyela obunembile kanye nokucatshangelwa ngokucophelela izici ezahlukahlukene. Kuqala ngokuklama ukwakheka kwemizila, kucatshangelwa ukusetshenziswa okuhlosiwe, isivinini sesitimela, kanye nendawo. Uma umklamo usuqediwe, inqubo yokwakha iqala ngezinyathelo ezilandelayo ezibalulekile:

1. Ukumba kanye nesisekelo: Ithimba lokwakha lilungisa inhlabathi ngokumba indawo bese lakha isisekelo esiqinile sokusekela isisindo kanye nokucindezeleka okubangelwa yizitimela.

2. Ukufakwa kwe-Ballast: Kubekwa ungqimba lwamatshe aqoshiwe, olwaziwa ngokuthi i-ballast, phezu kwendawo elungisiwe. Lokhu kusebenza njengengqimba ebamba ukushaqeka, enikeza ukuzinza, futhi kusiza ukusabalalisa umthwalo ngokulinganayo.

3. Izibopho Nokubopha: Izibopho zokhuni noma zekhonkrithi zibe sezifakwa phezu kwe-ballast, zilingisa isakhiwo esifana nohlaka. Lezi zibopho zinikeza isisekelo esiphephile semizila yesitimela yensimbi. Ziboshwa kusetshenziswa izipikili noma ama-clip athile, okuqinisekisa ukuthi zihlala ziqinile endaweni yazo.

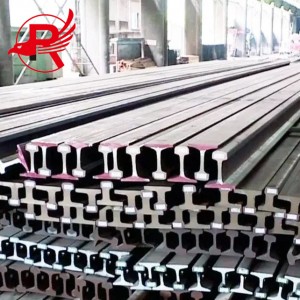

4. Ukufakwa Kwesitimela: Izinsimbi zesitimela zensimbi ezingamamitha ayi-10, ezivame ukubizwa ngokuthi izinsimbi ezijwayelekile, zibekwe ngokucophelela phezu kwezibopho. Njengoba zenziwe ngensimbi yekhwalithi ephezulu, lezi zindlela zinamandla amakhulu nokuqina.

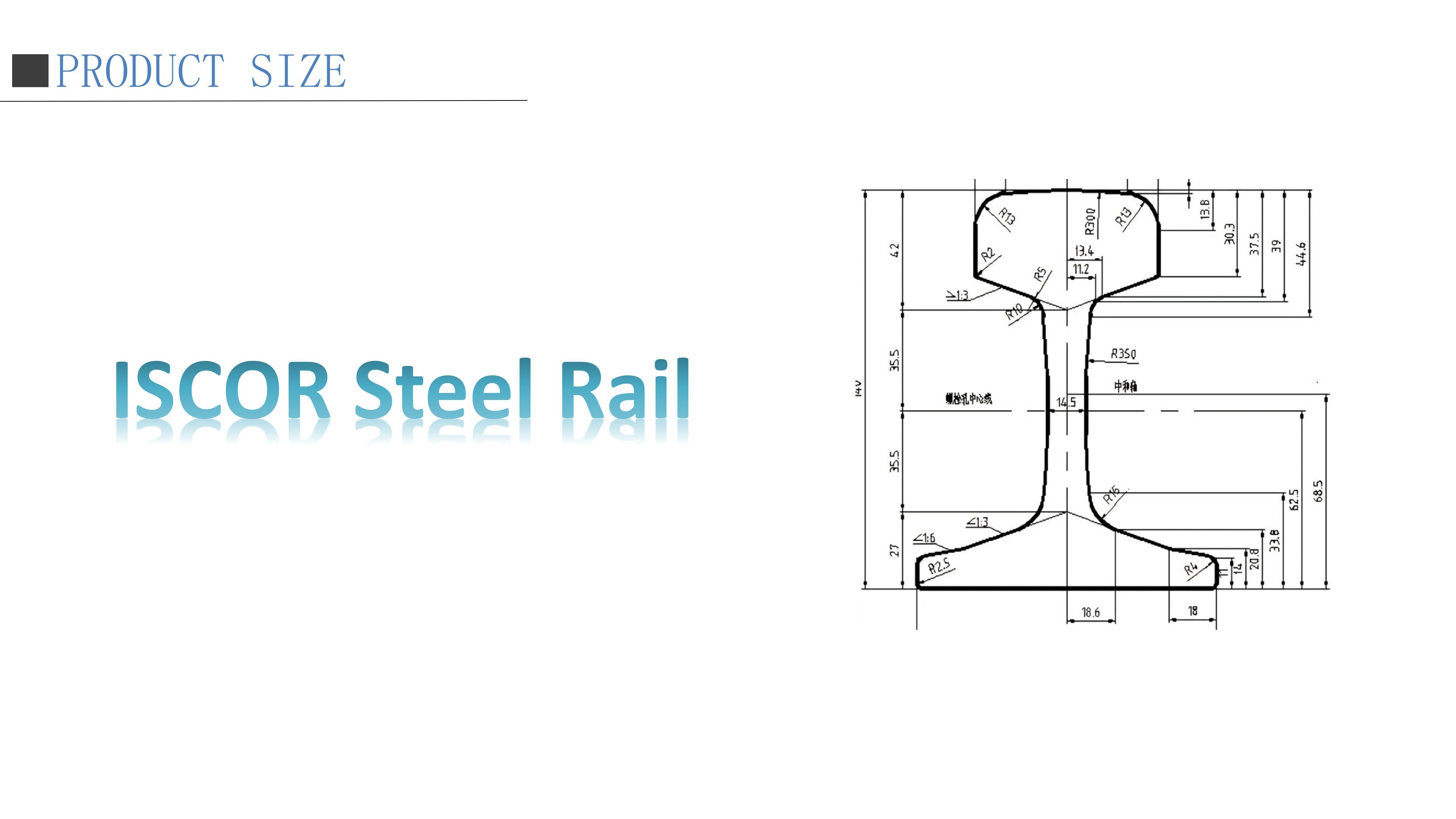

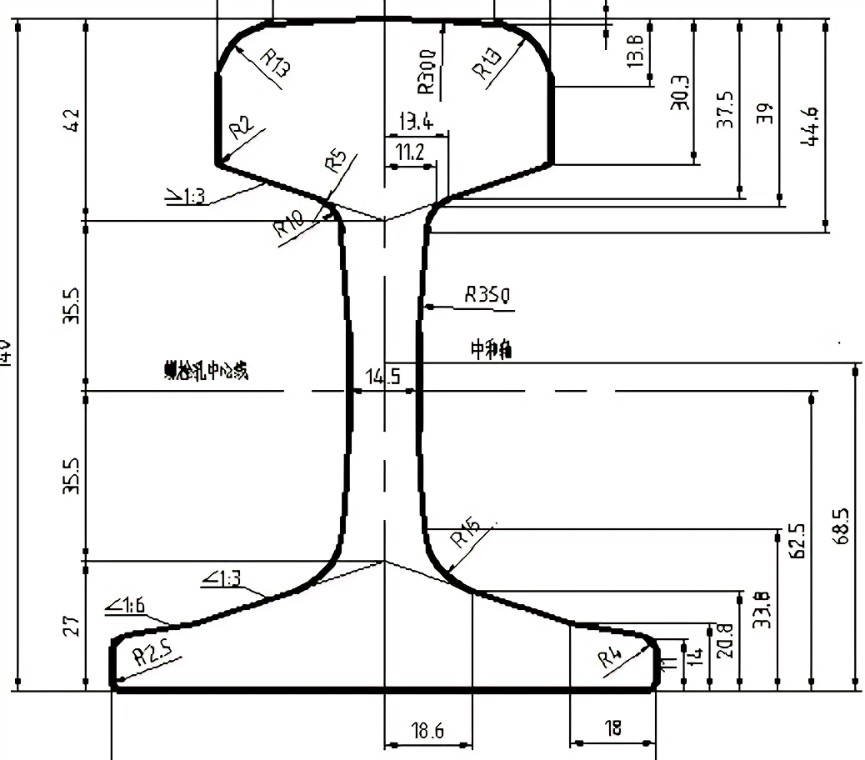

USAYIZI WOMKHIQIZO

Uhlobo namandlaisitimela sisendlelenizibonakaliswa ngama-kg/m. Uma isisindo sesitimela sisinda ngemitha, umthwalo waso uba mkhulu. Imizila yesitimela sokuqala emhlabeni yayingama-18kg/m, kanti imizila enzima kakhulu yayise-United States, inesisindo esingama-77kg/m.

| Isitimela sensimbi esijwayelekile se-ISCOR | |||||||

| imodeli | usayizi (mm) | into ethile | ikhwalithi yezinto ezibonakalayo | ubude | |||

| ububanzi bekhanda | ukuphakama | ibhodi lesisekelo | ukujula kokhalo | (kg/m) | (m) | ||

| A(mm) | I-B(mm) | C(mm) | D(mm) | ||||

| 15KG | 41.28 | 76.2 | 76.2 | 7.54 | 14.905 | 700 | 9 |

| 22KG | 50.01 | 95.25 | 95.25 | 9.92 | 22.542 | 700 | 9 |

| 30KG | 57.15 | 109.54 | 109.54 | 11.5 | 30.25 | 900A | 9 |

| 40KG | 63.5 | 127 | 127 | 14 | 40.31 | 900A | 9-25 |

| 48KG | 68 | 150 | 127 | 14 | 47.6 | 900A | 9-25 |

| 57KG | 71.2 | 165 | 140 | 16 | 57.4 | 900A | 9-25 |

Isitimela sensimbi se-ISCOR:

Imininingwane: 15kg, 22kg, 30kg, 40kg, 48kg, 57kg

Okujwayelekile: ISCOR

Ubude: 9-25m

IPHROJEKTHI

Uhlobo lweisitimela sisendleleniIsisindo sesitimela silinganiswa ngamakhilogremu esisindo sesitimela ngemitha ubude. Izinsimbi ezisetshenziswa ezitimeleni zaseShayina zifaka phakathi amakhilogremu angu-75/m, amakhilogremu angu-60/m, amakhilogremu angu-50/m, amakhilogremu angu-43/m kanye namakhilogremu angu-38/m.

INZUZO

1. Izici zemizila

1. Amandla aphezulu: Ngemva kokuklama okuhle kanye nefomula yezinto ezikhethekile, ojantshi banamandla okugoba aphezulu kanye namandla okucindezela, futhi bangakwazi ukumelana nomthwalo osindayo kanye nomthelela wesitimela, okuqinisekisa ukuphepha nokuzinza kokuthuthwa kwesitimela.

2. Ukumelana nokuguguleka: Ubuso besitimela bunobulukhuni obukhulu kanye ne-coefficient encane yokungqubuzana, okungamelana nokuguguleka kwamasondo esitimela kanye nemizila futhi kwandise impilo yesevisi.

3. Ukuqina okuhle: Ama-rails anobukhulu obuqondile bejometri kanye nobukhulu obuqinile obuqondile nobuqondile, okungaqinisekisa ukusebenza kahle kwesitimela futhi kunciphise umsindo nokudlidliza.

4. Ukwakhiwa okulula: Ama-rails angaxhunywa kunoma yibuphi ubude ngokusebenzisa ama-joint, okwenza kube lula ukufaka nokufaka esikhundleni ama-rails.

5. Izindleko zokulungisa eziphansi: Izitimela zizinzile futhi zithembekile ngesikhathi sokuthuthwa, futhi zinezindleko zokulungisa eziphansi.

2. Ukusetshenziswa kwemizila

1. Ezokuthutha ngesitimela: Izinsimbi zensimbi zisetshenziswa kabanzi kwezokuthutha ngesitimela, okuhlanganisa ezokuthutha ngabagibeli besitimela kanye nezimpahla, izitimela ezingaphansi komhlaba, izitimela ezihamba ngesivinini esikhulu, njll., futhi ziyizingxenye eziyisisekelo zezokuthutha ngesitimela.

2. Ukuthunyelwa kwezimpahla echwebeni: Izinsimbi zokuthutha izimpahla zensimbi zisetshenziswa emikhakheni yezokuthutha njengezindawo zokuthutha izimpahla njengemishini yokuphakamisa, imishini yokuthutha izimpahla equkethe amakhonteyina, njll. ukuze kube lula ukulayisha, ukukhulula impahla kanye nokuthutha amakhonteyina kanye nempahla.

3. Ukuthuthwa kwezimayini: Izitimela zensimbi zingasetshenziswa ezimayini nasezindaweni zezimayini njengemishini yokuthutha ngaphakathi kwezimayini ukuze kube lula ukumba nokuthuthwa kwezimayini.

Ngamafuphi, njengengxenye eyisisekelo kwezokuthutha ngezitimela, ojantshi banezinzuzo zamandla aphezulu, ukumelana nokuguguleka, ukuzinza okuqinile, ukwakhiwa okulula, kanye nezindleko zokulungisa eziphansi. Zisetshenziswa kabanzi ezitimeleni, ezokuthutha ezichwebeni, ezokuthutha zezimayini nakweminye imikhakha.

ISICELO

Abalele bathwala ingcindezi evela ku-imigwaqokuzo zonke izinhlangothi futhi zidluliselwa ngokunwebeka embhedeni wethrekhi. Ngesikhathi esifanayo, zigcina kahle isimo sejometri yethrekhi, ikakhulukazi igeyiji yethrekhi kanye nesiqondiso. Izilali kufanele zibe namandla adingekayo, ukunwebeka kanye nokuqina, futhi kufanele zikwazi ukulungisa kalula imisele futhi zibe nekhono lokumelana nokufuduka okude nokuphambeneyo.

UKUPHAKISHA NOKUTHUMELA

1. Ezokuthutha ngesitimela

Imizila emide iyinto ebalulekile ekwakhiweni kwezitimela, ngakho-ke ukuthuthwa kwezitimela kuyindlela ekhethwayo yokuthuthwa kwezitimela ende. Ukuthuthwa kwezitimela kunezinzuzo zomthamo omkhulu wokuthutha, ukusebenza kahle okuphezulu, ukuphepha kanye nokuthembeka. Ngensizakalo yokuthuthwa kwezitimela yenkampani yesitimela, imizila emide ingathuthwa ngqo kusuka kumenzi iye endaweni yokwakha. Ngesikhathi senqubo yokuthutha, inkampani yesitimela izokwenza ukuhlolwa njalo kwezitimela ezinde ukuqinisekisa ukuphepha ngesikhathi sokuthuthwa.

2. Ezokuthutha ngomgwaqo

Uma kuqhathaniswa nezokuthutha ngesitimela, ezokuthutha ngemigwaqo zinemikhawulo emincane ngobude bemizila emide futhi zingakhetha indlela yokuthutha eguquguqukayo. Njengoba inani lokuthutha kwezokuthutha ngemigwaqo lincane, ezokuthutha ngemigwaqo ngokuvamile zisetshenziselwa ezokuthutha ezikude, njengokuthutha kwesifunda phakathi kwamadolobha noma ngaphakathi kwamadolobha.

3. Ukuthuthwa kwamanzi

Ukuthuthwa kwamanzi kuyindlela yokuthutha ekwazi ukuthutha izinto ezinkulu futhi inezinzuzo ezinkulu zokuthutha izitimela ezinde. Ukuthuthwa kwamanzi ngokuvamile kwenziwa yimikhumbi, enezici zebanga elide lokuthuthwa kanye nomthamo omkhulu wokuthutha. Kodwa-ke, ngenxa yokuthi ukukhethwa komzila wokuthuthwa kwamanzi kulinganiselwe, futhi ezinye izindlela zokuhamba kudingeka zixhunywe phakathi kwendawo yokuqala nendawo yokugcina yezimpahla, kubalulekile ukunaka izinkinga zomzila kanye nokuxhumana ngesikhathi senqubo yangempela yokuthuthwa.

Sekukonke, ukuthuthwa kwezitimela kuyindlela engcono kakhulu yokuthutha ojantshi abade, kodwa kufanele kuqashelwe ukuthi ngesikhathi senqubo yangempela yokuthuthwa, kudinga ukuhlanganiswa nezinye izindlela zokuthuthwa kwempahla. Ngesikhathi esifanayo, ukuthuthwa ngomgwaqo kanye nokuthuthwa ngamanzi nakho kunezinzuzo zako ezihlukile futhi kudinga ukukhethwa ngokwezimo zangempela. Ngamafuphi, ukukhetha indlela efanele yokuthuthwa kwezitimela ezinde kungaqinisekisa ngempumelelo ukusebenza kahle kwezokuthutha, kunciphise izindleko zokuhamba, futhi kuthuthukise ikhwalithi yokwakhiwa kwephrojekthi.

UKWAKHIWA KWEMIKHIQIZO

Kwenziwe eShayina, isevisi yekilasi eliphezulu, ikhwalithi ephezulu, idumile emhlabeni jikelele

1. Umphumela Wesilinganiso: Inkampani yethu inochungechunge olukhulu lokuhlinzeka kanye nefektri enkulu yensimbi, efinyelela imiphumela emikhulu kwezokuthutha kanye nokuthengwa kwempahla, futhi iba yinkampani yensimbi ehlanganisa ukukhiqiza kanye nezinsizakalo.

2. Ukwehlukahluka komkhiqizo: Ukwehlukahluka komkhiqizo, noma iyiphi insimbi oyifunayo ingathengwa kithi, ikakhulukazi ehilelekile ezakhiweni zensimbi, izinsimbi zensimbi, izinqwaba zeshidi lensimbi, amabhulakhethi e-photovoltaic, insimbi yesiteshi, amakhoyili ensimbi ye-silicon neminye imikhiqizo, okwenza kube lula ukukhetha uhlobo lomkhiqizo olufunayo ukuze luhlangabezane nezidingo ezahlukene.

3. Ukunikezwa okuzinzile: Ukuba nomugqa wokukhiqiza ozinzile kanye nochungechunge lokunikezwa kunganikeza ukunikezwa okuthembekile. Lokhu kubaluleke kakhulu kubathengi abadinga insimbi eningi.

4. Ithonya lomkhiqizo: Linethonya lomkhiqizo eliphezulu kanye nemakethe enkulu

5. Isevisi: Inkampani enkulu yensimbi ehlanganisa ukwenza ngokwezifiso, ezokuthutha kanye nokukhiqiza

6. Ukuncintisana kwentengo: intengo enengqondo

*Thumela i-imeyili ku-[i-imeyili ivikelwe]ukuthola ikhotheshini yamaphrojekthi akho

Imibuzo Evame Ukubuzwa

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, bese kuthi imali esele ibe yi-B/L. EXW, FOB, CFR, CIF.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.