Ikhwalithi Ephezulu h16 x 101 150x150x7x10 Q235 Q345b I-Hot Rolled IPE HEA HEB EN Insimbi Enomumo Ofana No-H

INQUBO YOKUKHIQIZWA KOMKHIQIZO

Lezi zimpawu zisho izinhlobo ezahlukene zeImisebe ye-IPE esekwengobukhulu kanye nezakhiwo zazo:

- I-HEAIzingxenye zensimbi (IPN): Lezi yizinsika zensimbi ezimise okwe-I ezinama-flange abanzi kanye nama-web ajiyile, afanele ukusetshenziswa kwesakhiwo esidinga amandla aphezulu okuthwala imithwalo.

- I-HEBIzingxenye zensimbi (IPB): Lezi yizingodo zensimbi ezimise okwe-I ezinobubanzi obuphakathi kanye nobukhulu be-flange, ezivame ukusetshenziswa ezakhiweni ezahlukene zezakhiwo.

- Izingxenye zensimbi zohlobo lwe-HEM: Lezi yizingxenye zensimbi ze-I-beam ezinokuphakama kwe-flange enkulu kanye nobubanzi be-flange obuncane, okuholela emandleni aphezulu kanye nomthamo wokuthwala umthwalo. Izinhlobo ezahlukene zezingxenye zensimbi eziwelayo zinezici zazo zokwakheka kwesakhiwo; ngakho-ke, kumaphrojekthi athile obunjiniyela, uhlobo olufanele kufanele lukhethwe ngokusekelwe ezidingweni zangempela.

USAYIZI WOMKHIQIZO

| Ukuqokwa | I-Unt Isisindo kg/m) | Isigaba Esijwayelekile ukumiswa mm | Isigaba Ama (cm² | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Ukuqokwa | Iyunithi Isisindo kg/m) | Isigaba Esijwayelekile Ukushintshashintsha (mm) | Isigaba Indawo (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| I-HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

IZICI

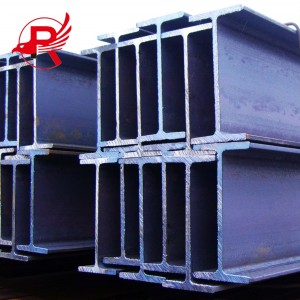

Izingxenye zensimbi ze-HEA, HEB, kanye ne-HEM ziyizinhlobo zemishayo yensimbi ye-IPE ejwayelekile yaseYurophu (isigaba esinomfanekiso ongu-I) esetshenziswa kabanzi ekwakheni nasebunjiniyelani bezakhiwo. Nazi izici eziyinhloko zohlobo ngalunye:

Ingxenye yensimbi ye-HEA (IPN):

Ububanzi obukhulu kanye nobukhulu be-flange

Ifanele izakhiwo ezinemithwalo esindayo

Inikeza amandla amahle okuthwala umthwalo kanye namandla okugoba

Ingxenye yensimbi ye-HEB (IPB):

Ububanzi kanye nobukhulu be-flange obumaphakathi

Isebenziseka ngezindlela eziningi, ivame ukusetshenziswa ezakhiweni ezahlukene zezakhiwo

Ihlanganisa amandla nezinzuzo ezilula

Ingxenye yensimbi ye-HEM:

Ukuphakama kwe-flange enkulu kanye nobubanzi obuncane

Inikeza amandla aphezulu kanye nomthamo wokuthwala umthwalo

Ifanele izakhiwo ezinemithwalo esindayo kanye nokucindezeleka okukhulu

EI-NHInsimbi Ebunjiwe

Ibanga: EN10034:1997 EN10163-3:2004

Imininingwane: I-HEA HEB ne-HEM

Okujwayelekile: EN

UKUHLOLWA KOMKHIQIZO

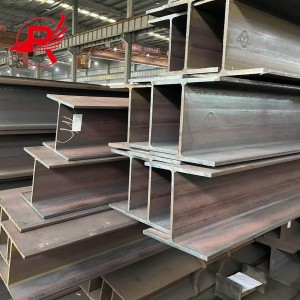

Izidingo ezibalulekile zokuhlola insimbi enomumo we-H zifaka phakathi izici ezilandelayo:

Ikhwalithi Yokubukeka: Ukubukeka kwensimbi enomumo we-H kufanele kuhlangabezane nezindinganiso ezifanele kanye nezidingo zamakhasimende. Ubuso kufanele bube bushelelezi futhi bulingane, bungabi namaqhubu asobala, imihuzuko, amabala okugqwala, nezinye izinkinga.

Ubukhulu beJomethri: Ubude, ububanzi, ukuphakama, ubukhulu bewebhu, kanye nobukhulu be-flange yensimbi enomumo we-H kufanele kuhambisane nezindinganiso ezifanele kanye nezidingo zamakhasimende.

Ukuqonda: Ukuqonda kwensimbi enomumo we-H kufanele kuhlangabezane nezindinganiso ezifanele kanye nezidingo zamakhasimende. Lokhu kungaqinisekiswa ngokulinganisa ukufana kweziphetho ezimbili noma ukusebenzisa igeyiji yokuqonda.

Ukugoqa: Ukugoqa kwensimbi enomumo we-H kufanele kuhlangabezane nezindinganiso ezifanele kanye nezidingo zamakhasimende. Lokhu kungaqinisekiswa ngokulinganisa ukugoqa kwezinhlangothi noma ukusebenzisa isihloli sokugoqa.

Ukuphambuka Kwesisindo: Isisindo sensimbi enomumo we-H kufanele sihlangabezane nezindinganiso ezifanele kanye nezidingo zamakhasimende. Ukuphambuka kwesisindo kungahlolwa ngokukala.

Ukwakheka Kwamakhemikhali: Uma insimbi enobunjwa obungu-H idinga ukushiselwa noma okunye ukucutshungulwa, ukwakheka kwayo kwamakhemikhali kufanele kuhlangabezane nezindinganiso ezifanele kanye nezidingo zamakhasimende.

Izakhiwo Zomshini: Izakhiwo zomshini zensimbi enomumo we-H kufanele zihlangabezane nezindinganiso ezifanele kanye nezidingo zamakhasimende, okuhlanganisa amandla okunamathela, amandla okukhiqiza, ukunwebeka, njll.

Ukuhlolwa Okungabhubhisi: Uma kudingeka ukuhlolwa okungabhubhisi kwensimbi enomumo we-H, kufanele kwenziwe ngokwezindinganiso ezifanele kanye nezidingo zamakhasimende ukuqinisekisa ukuthi ikhwalithi yayo yangaphakathi ihlangabezana nezimfuneko.

Ukupakishwa Nokulebula: Ukupakishwa nokufakwa kwensimbi enomumo we-H kufanele kuhambisane nezindinganiso ezifanele kanye nezidingo zamakhasimende, okwenza kube lula ukuthuthwa nokugcinwa.

Ngamafuphi, lapho kuhlolwa insimbi enomumo we-H, zonke izidingo ezingenhla kufanele zicatshangelwe ngokuphelele ukuqinisekisa ukuthi ikhwalithi ihlangabezana nezindinganiso ezifanele kanye nezidingo zamakhasimende, ngaleyo ndlela kuhlinzekwe abasebenzisi ngemikhiqizo yensimbi enomumo we-H esezingeni eliphezulu.

ISICELO

Imisebe ye-HEA, HEB, kanye ne-HEMzinezinhlobo eziningi zezicelo embonini yokwakha nobunjiniyela bezakhiwo. Ezinye izindlela ezivamile zokusebenzisa zifaka:

- Amaphrojekthi Okwakha: Lezi zingxenye zensimbi zivame ukusetshenziswa ekwakhiweni kwezakhiwo zezentengiselwano nezezimboni, zinikeza ukwesekwa kwezitezi, uphahla, nezinye izakhiwo ezithwala imithwalo.

Ubunjiniyela Bebhuloho: Zisetshenziswa ekwakhiweni kwamabhuloho, zisekela idekhi lamabhuloho nezinye izingxenye zesakhiwo.

Izakhiwo Zezimboni: Izingxenye zensimbi ze-HEA, HEB, kanye ne-HEM zisetshenziswa kabanzi ekwakhiweni kwezakhiwo zezimboni ezifana nezindawo zokugcina impahla, amafektri, kanye nezindawo zokugcina impahla.

Amafreyimu Esakhiwo: Angasetshenziswa ukwakha amafreyimu esakhiwo sezakhiwo ezinkulu kanye namaphrojekthi engqalasizinda, enikeza ukwesekwa kwezindonga, ama-facade, nezinye izakhi zesakhiwo.

Ukusekelwa Kwemishini: Lezi zingxenye zensimbi zingasetshenziswa ukusekela imishini esindayo nemishini ezindaweni ezahlukene zezimboni.

Amaphrojekthi Engqalasizinda: Izingxenye zensimbi ze-HEA, HEB, kanye ne-HEM nazo zisetshenziswa ekwakhiweni kwamaphrojekthi engqalasizinda njengemigudu, izikhumulo zezindiza, kanye nezitshalo zikagesi.

Ngamafuphi, lezi zingxenye zensimbi zidlala indima ebalulekile kumaphrojekthi ahlukahlukene okwakha nobunjiniyela, zinikeza ukwesekwa kwesakhiwo okuqinile nokuthembekile. Ukuguquguquka kwazo, amandla, kanye nomthamo wokuthwala imithwalo kuzenza zibe yinto ebalulekile ekwakheni izakhiwo zanamuhla kanye nengqalasizinda.

UKUPHAKISHA NOKUTHUMELA

Ukupakishwa Nokuvikelwa

Ukupakishwa okufanele kubalulekile ekuqinisekiseni ikhwalithi yensimbi enomumo we-ASTM A36 ngesikhathi sokuthuthwa nokugcinwa kwayo: Sebenzisa izintambo/amabhande ensimbi aqinile ukuze ubophe imishayo yensimbi ngokuphephile ukuze uvimbele ukuguguleka nokonakala; Sebenzisa izinto ezingamelani nesimo sezulu ezifana nepulasitiki noma ama-tarpaulin angangeni manzi ukuze uvikele umswakama nothuli, uvimbele ukugqwala.

Ukulayisha, Ukukhipha, Nokuvikela

Phatha imishayo yensimbi epakishiwe ngokucophelela ngesikhathi sokulayisha nokukhipha impahla: Sebenzisa imishini yokuphakamisa efanele njenge-forklift noma ama-crane ukuqinisekisa ukuphepha nokusebenza kahle; Uma ulayisha, hambisa imishayo yensimbi ngokulinganayo bese uyilungisa kahle ukuze uvimbele umonakalo wesakhiwo; Ngemva kokulayisha, qinisa impahla ngezintambo, amaketanga, njll., ukuqinisekisa ukuzinza nokuvimbela ukuguquka ngesikhathi sokuthuthwa. Lesi sifinyezo esifushane sigxile ezinqubweni ezibalulekile kanye nezidingo, okwenza kube lula ukuqonda ngokushesha ulwazi olubalulekile. Uma ufisa ukwenza lula noma yisiphi isigaba noma wengeze imininingwane ethile (njengezinhlobo zezinto zokuzivikela), sicela usazise.

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, bese kuthi imali esele ibe yi-B/L. EXW, FOB, CFR, CIF.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.