| Isigaba Sokwenza Ngokwezifiso | Izinketho Ezitholakalayo | Incazelo / Ububanzi | Inani Elincane Le-oda (MOQ) |

|---|---|---|---|

| Ukwenza Ngokwezifiso Ubukhulu | Ububanzi (B), Ukuphakama (H), Ubukhulu (t), Ubude (L) | Ububanzi 50–350 mm, Ukuphakama 25–180 mm, Ubukhulu 4–14 mm, Ubude 6–12 m (kungenziwa ngezifiso ngephrojekthi ngayinye) | Amathani angu-20 |

| Ukucubungula Ukwenza Ngokwezifiso | Ukubhoboza, Ukusika Imigodi, Umshini Wokugcina, Ukushisela Okulungisiwe | Iziphetho zinganqunywa, zibekwe nge-beveled, zifakwe imiphetho, noma zishiselwe; imishini enembile yokuxhumana okukhethekile kwesakhiwo | Amathani angu-20 |

| Ukwenza Ngokwezifiso Ukwelashwa Komphezulu | I-Hot-Dip Galvanized, Pendiwe, I-Powder Coating | Ukwelashwa kwendawo kukhethwe ngokusekelwe endaweni ezungezile, ukuvikelwa kokugqwala, kanye nokuphila kwenkonzo | Amathani angu-20 |

| Ukumaka Nokwenza Ngokwezifiso Ukupakisha | Amalebula Angokwezifiso, Ukupakisha Okuthunyelwa Ngaphandle, Indlela Yokuthumela | Amalebula anomazisi wephrojekthi, amazinga, noma imininingwane; ukupakisha okufanelekela isitsha noma ukuthuthwa okuyisicaba | Amathani angu-20 |

Izakhiwo Zensimbi Ze-ASTM Ezisezingeni Eliphezulu Amaphrofayili Ensimbi Eshisayo Ehlanganisiwe Engamasentimitha angu-3 Isiteshi Esihlanganisiwe Se-C

Imininingwane Yomkhiqizo

| Into | Imininingwane |

|---|---|

| Igama Lomkhiqizo | Isiteshi se-C esifakwe i-Slot |

| Okujwayelekile | I-ASTM A36 / ASTM A572 / ASTM A992 |

| Izinketho Zezinto Ezibalulekile | Insimbi yekhabhoni egoqekile eshisayo / Insimbi yesakhiwo egayiwe eshisayo ene-C Channel (ASTM A36) |

| Osayizi Abajwayelekile | Amaphrofayili esiteshi se-C: C2×2″ – C6×6″ (osayizi abangokwezifiso bayatholakala) |

| Uhlobo Lokufaka | Uphahla lwensimbi oluyisicaba, olufakwe phansi, umugqa owodwa noma emibili, ukuthambekela okuqinile noma okulungisekayo |

| Izicelo | Uphahla, Ezentengiselwano Nezimboni, Indawo Yokufaka Emhlabathini, Iziteshi Zokuguqula, Izinhlelo Ze-PV Yezolimo |

| Isikhathi Sokulethwa | Izinsuku zokusebenza eziyi-10–25 |

Usayizi Wesiteshi se-C esifakwe i-ASTM

| Ukuphakama (H) | Ububanzi beFlange (B) | Ubukhulu bewebhu (tw) | Ubukhulu be-Flange (tf) | Isisindo (lb/ft) | Uhlobo lwesikhala |

|---|---|---|---|---|---|

| 2 in (50 mm) | 1.5 – 2 in (38–51 mm) | 0.12 – 0.19 in (3–4.8 mm) | 0.16 – 0.25 in (4–6.4 mm) | 3.5 – 5.2 | Isiyingi / Eside |

| Amasentimitha angu-3 (76 mm) | 1.5 – 2 in (38–51 mm) | 0.14 – 0.19 in (3.5–4.8 mm) | 0.19 – 0.25 in (4.8–6.4 mm) | 3.8 – 5.5 | Isiyingi / Eside |

| Amasentimitha angu-4 (100 mm) | 1.75 – 2.5 in (45–64 mm) | 0.16 – 0.25 in (4–6.4 mm) | 0.22 – 0.31 in (5.5–8 mm) | 6 – 9 | Isiyingi / Eside |

| Amasentimitha angu-6 (152 mm) | 2 – 3 inches (51–76 mm) | 0.19 – 0.31 in (4.8–8 mm) | 0.25 – 0.38 in (6.4–9.7 mm) | 9 – 15 | Isiyingi / Eside |

| 8 in (203 mm) | 2.5 – 3.5 in (64–89 mm) | 0.25 – 0.44 in (6.4–11 mm) | 0.31 – 0.50 in (8–12.7 mm) | 14 – 22 | Isiyingi / Eside |

Ithebula Lokuqhathanisa Nokubekezelelana Kwesiteshi Se-ASTM Slotted C

| Ipharamitha | Ububanzi/Usayizi Ojwayelekile | Ukubekezelelana kwe-ASTM | Amazwi |

|---|---|---|---|

| Ububanzi (B) | 1.5 – 3.5 in (38 – 89 mm) | ±1/16 in (±1.5 mm) | Ububanzi beflange ye-C-Channel ejwayelekile |

| Ukuphakama (H) | 2 – 8 in (50 – 203 mm) | ±1/16 in (±1.5 mm) | Ukujula kwewebhu kwesiteshi |

| Ubukhulu (t) | 0.12 – 0.44 in (3 – 11 mm) | ±0.01 in (±0.25 mm) | Iziteshi ezijiyile zisekela imithwalo ephezulu |

| Ubude (L) | I-20 ft / 6 m ejwayelekile, iyatholakala ngobude obunqunyiwe | ±3/8 in (±10 mm) | Ubude obungokwezifiso bungacelwa |

| Ububanzi beFlange | Bona osayizi besigaba | ±1/16 in (±1.5 mm) | Kuncike ochungechungeni lweziteshi kanye nezidingo zomthwalo |

| Ubukhulu bewebhu | Bona osayizi besigaba | ±0.01 in (±0.25 mm) | Kubalulekile ekugobeni nasekuthwaleni umthwalo |

Okuqukethwe okwenziwe ngokwezifiso kwesiteshi se-C okufakwe ku-ASTM

Ukuqedwa Komphezulu

Izindawo Ezivamile

Ingaphezulu elifakwe i-hot-dip (≥ 80–120 μm)

Ingaphezulu Lopende Lokufutha

Isicelo

1. Ukusekelwa Kwesakhiwo Sezakhiwo – Amafreyimu Esiteshi C

Zilungele ozimele bokwakha ikhaya noma ibhizinisi, zinokusekelwa okuqinile nokuzinzile kwezindonga, uphahla kanye nezindawo zokulala.

2. Izicelo Zezimboni Nezinzima

Isiteshi C Esinamandla Aphezulu: I-rack ye-C-Channel esindayo iqinile futhi ihlala isikhathi eside, engaklanyelwa ozimele bemishini, ama-rack ezimboni, izinhlelo zokugcina, njll.

3. Izakhiwo Eziguquguqukayo Nezingaguquguquki

Ifanelekela ama-braces alungisekayo, amaphaneli ase-prefab, noma ukuhlanganiswa kwe-modular, okunikeza ukuguquguquka nokufakwa okulula.

4. Izakhiwo Zezolimo Nezangaphandle

Iziteshi ze-C zilungele izindawo zokugcina izithombo, ukwesekwa kokufakwa kwelanga, uthango, noma izindawo zokukhosela imfuyo - inhlanganisela ehlakaniphile yamandla esakhiwo kanye nokusimama kwemvelo.

Izinzuzo Zethu

Umthombo Othembekile: Insimbi esezingeni eliphezulu eyenziwe eShayina enomsebenzi ozinzile.

Amandla Okukhiqiza Aqinile: Insizakalo ye-OEM/ODM, ukukhiqizwa ngobuningi kanye nokulethwa ngesikhathi.

Izinhlobonhlobo Ezibanzi: Izinto ezenziwe ngensimbi, ama-rails, ama-sheet piles, i-channel, ama-bracket e-PV njalo njalo.

Ukunikezwa Okuzinzile: Siyakwamukela ukubeka ama-oda ngobuningi nangobuningi.

Umkhiqizo Othembekile: Irekhodi eliqinisekisiwe embonini yensimbi.

Ubuchwepheshe Besevisi: Izinsizakalo zokukhiqiza nezokuthutha.

Inani lemali: ikhwalithi ephezulu ngentengo encintisanayo.

*Thumela i-imeyili ku-[i-imeyili ivikelwe]ukuthola ikhotheshini yamaphrojekthi akho

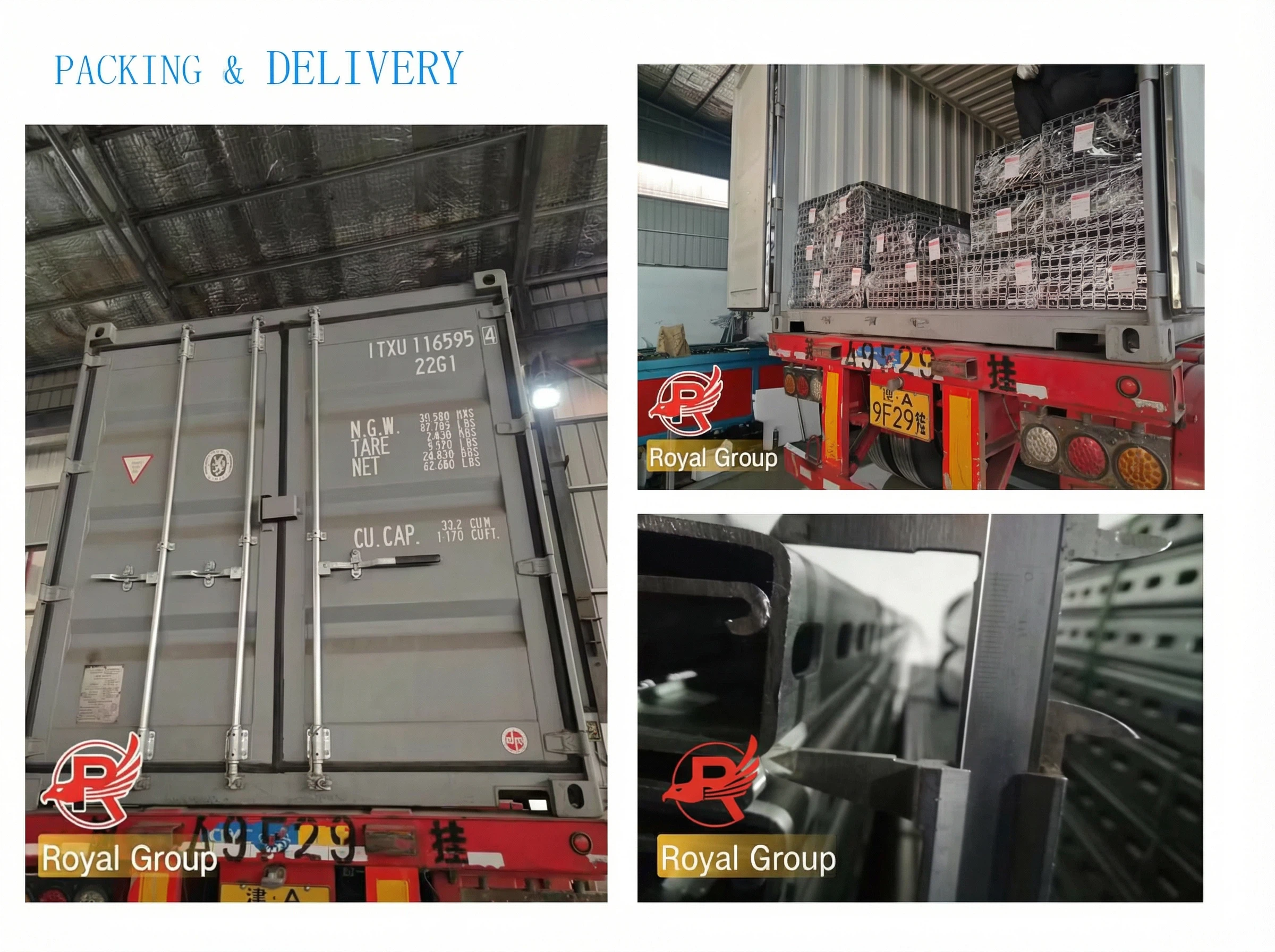

Ukupakisha Nokuthumela

UKUPHAKISHA

-

Isivikelo:Izinqwaba zigoqwa nge-tarpaulin engangeni manzi futhi zifaka izikhwama ezimbili kuya kwezingu-3 ze-desiccant ukuvimbela umswakama nokugqwala.

-

Ukubhinca:Izinqwaba ezinesisindo esingamathani angu-2-3 ziboshwe ngezintambo zensimbi ezingu-12-16 mm, ezifanele zonke izinhlobo zokuthutha.

-

Ukulebula:Amalebula ngesiNgisi nangesiSpanishi abonisa izinto, izinga le-ASTM, usayizi, ikhodi ye-HS, inombolo yebhetshi, kanye nombiko wokuhlolwa.

UKULETHWA

-

Ezokuthutha Emgwaqweni:Ukupakisha okuphephile, okungasheleli ukuze kuthunyelwe ibanga elifushane noma endaweni.

-

Ezokuthutha Ngesitimela:Izinqola zesitimela eziphelele ezisetshenziselwa ukuthunyelwa okuphephile ibanga elide.

-

Impahla Yasolwandle:Ukuthunyelwa okufakwe emathinini—ngobuningi, okomile, noma okuvulekile—kuye ngokuthi uya kuphi.

Ukulethwa Kwemakethe Yase-US:Isiteshi se-ASTM C saseMelika sihlanganiswe ngezintambo zensimbi futhi iziphetho zivikelwe, kanye nokwelashwa okungakhethwa kokulwa nokugqwala kwezokuthutha.

Imibuzo Evame Ukubuzwa

U: Ziyini izinto zokwakha?

A: Insimbi yekhabhoni eshisayo eyenziwe ngokwezifiso ngokubheka izidingo zephrojekthi kanye nezimo zemvelo.

Q: Singakwazi yini ukwenza umklamo ngokwezifiso?

A: Yebo, usayizi, i-angle yokuthambekela, ubude, izinto zokwakha, ukugqoka kanye nohlobo lwesisekelo kungenziwa ngokwezifiso zephahla, ezifakwe phansi, noma amaphrojekthi akhethekile.

Ikheli

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

I-imeyili

Ucingo

+86 13652091506