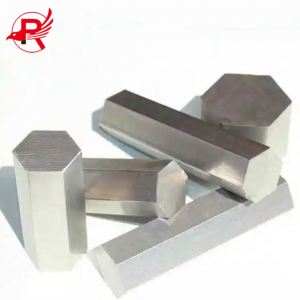

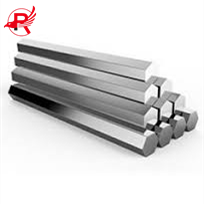

Umhlinzeki waseShayina Induku ye-Aluminium Enezinhlangothi Ezine-Extruded Hexagonal Ibha Ende ye-Hexagon 12mm 2016 astm 233

Imininingwane Yomkhiqizo

Induku ye-aluminiyamu enezinhlangothi eziyisithupha iwumkhiqizo we-aluminiyamu omise okwe-prism enezinhlangothi eziyisithupha, okuwumkhiqizo ovame ukusetshenziswa embonini.

Induku ye-aluminium enezinhlangothi eziyisithupha inezici zobukhulu obulula, ukuqina okuhle, amandla aphezulu kanye nokuqhuba kahle, futhi isetshenziswa kabanzi njengokushabalalisa ukushisa kanye nezingxenye zesakhiwo emishinini kagesi neye-elekthronikhi.

Ngenxa yezici zesakhiwo esinonxande, silungele kakhulu ukwenza izingxenye kanye nezimo ezihlukahlukene.

Imininingwane

Embonini yokukhiqiza imishini, isetshenziswa kakhulu ukukhiqiza izinhlobo ezahlukene ze-stamping dies; ekucubungulweni kwehadiwe, isetshenziselwa ukwenza amadivayisi ensimbi ahlukahlukene, amapayipi nezingxenye ezahlukahlukene ezibunjwe ngendlela ekhethekile; embonini yezimoto, ingasetshenziswa ezinhlelweni zokupholisa njengezinjini kanye nama-brake drums. Ipuleti lokungqubuzana elikuyo; ngaphezu kwalokho, ingasetshenziswa futhi njengento yokwelapha elwa nokugqwala kwemishini yamakhemikhali, njll.

Isicelo

1. Ifanele imikhiqizo kagesi neyegesi njengezingxenye zokushabalalisa ukushisa noma izingxenye zesakhiwo, njenge-radiator, ama-evaporator, ama-condenser namanye amadivayisi okushabalalisa ukushisa.

2. Isetshenziswa ohlelweni lokupholisa lwe-engine block embonini yezimoto kanye nepuleti lokungqubuzana esigubhuni samabhuleki; ingasetshenziswa futhi njengento yokwelapha yokulwa nokugqwala emishinini yemboni yamakhemikhali.

3. Ingathatha indawo yezingxenye zethusi njenge-solder ngesikhathi sokushisela, njenge: ikhanda lensimbi eligoqekayo ngogesi, umlomo wesibhamu somoya oshisayo, ucingo olugoqekayo, ibhola eligoqekayo njll.

4. Ingasetshenziswa futhi esikhundleni sendawo yokucima izingxenye zensimbi.

Izinto ze-aluminium. Okulandelayo kusebenzisa kakhulu i-aluminium alloy engu-6061 njengesibonelo ukwethula:

I-aluminium Alloy engu-6061

I-aluminium alloy engu-6061 iyi-alloy elapheka ngokushisa enokwakheka okuhle, ukushibilika, ukusebenza kahle, kanye namandla aphakathi, futhi isengaqhubeka nokusebenza kahle ngemva kokushibilika.

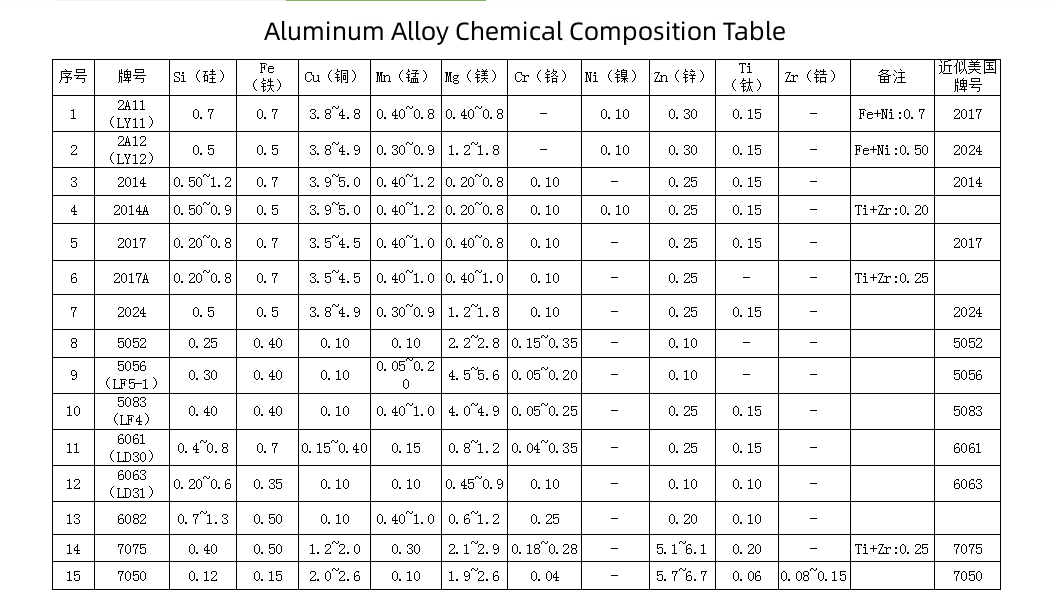

Ukwakheka kwamakhemikhali e-aluminium alloy angu-6061 (%):

Cu: 0.15~0.4 Mn:0.15 Mg:0.8~1.2Zn: 0.25 Cr: 0.04~0.35 Ti: 0.15 Si:0.4~0.8 Fe: 0.7 Al: ibhalansi

Isicelo Esiyinhloko: Sisetshenziswa kabanzi ezingxenyeni ezahlukene zesakhiwo sezimboni ezidinga amandla athile kanye nokumelana nokugqwala okuphezulu, njengamaloli okukhiqiza, izakhiwo zemibhoshongo, imikhumbi, ama-tram, kanye nezimoto zesitimela. Izakhiwo ze-aluminium alloy ezingama-6061:

Amandla okuqina okuqine kakhulu e-aluminium alloy engu-6061 angama-124MPa, amandla okuqina okuqinela angama-5.2MPa, izinga lokunwebeka lingu-25.0%, i-modulus yokunwebeka ingu-68.9 GPa, kanti amandla okuqina okugoba angama-28MPa.

I-6061 ivame ukusetshenziswa ezintweni zokufaka izindiza, amaloli, izakhiwo zemibhoshongo, amapayipi, imikhumbi, izindiza, izindiza, ezokuvikela kanye nezinye izinhlelo zokusebenza zokwakha ezidinga amandla, ukushibilika kanye nokumelana nokugqwala.

I-aluminium alloy engu-6061 inezinzuzo ezilandelayo: 1. I-alloy enamandla aphezulu elapheka ngokushisa. 2. Izakhiwo ezinhle zemishini. 3. Ukusetshenziswa okuhle. 4. Kulula ukuyicubungula, ukumelana nokuguguleka okuhle. 5. Ukumelana okuhle nokugqwala kanye nokumelana nokugqwala

I-aluminium alloy engu-6061 ivame ukusetshenziswa ezintweni zokufaka izindiza, amaloli, izakhiwo zemibhoshongo, amapayipi, imikhumbi, izindiza, izindiza, ezokuvikela kanye nezinye izinhlelo zokusebenza zokwakha ezidinga amandla, ukushibilika kanye nensimu yokumelana nokugqwala. Njenge: izingxenye zezindiza, amagiya kanye nemishayo, izingxenye zefuse, imishayo yezinsimbi kanye namagiya, izingxenye zokuphepha ze-jump valve, ama-turbine, okhiye, njll.

I-alloy ye-A-Mg-Si enamandla aphakathi nendawo, i-plasticity enhle kanye nokumelana nokugqwala okuhle kakhulu. Ikakhulukazi, ayikho imikhuba yokuqhekeka kokugqwala kokucindezeleka, ukushintshwa kwayo kuhle kakhulu, ukumelana nokugqwala nokusebenza kokubanda kuhle, uhlobo lokusetshenziswa okubanzi. I-alloy ethembisayo kakhulu. Ingafakwa i-anodized futhi ipendwe, futhi ingapendwa nge-enamel, efanelekile ezintweni zokuhlobisa zokwakha. Iqukethe inani elincane le-Cu, ngakho-ke amandla ayo aphezulu kunalawo angu-6063, kodwa iyazwela ekucimeni.

3, Izici kanye Nezindlela Zokuthuthukiswa Kwezigaba Zesitimela:

Futhi iphakeme kune-6063. Ukucima umoya akukwazi ukufezwa ngemva kokukhipha umoya, futhi kudinga ukulungiswa kabusha nokucinywa ukuze kutholakale amandla aphezulu.

Izinto eziyinhloko zokuhlanganisa igolide laseTaiwan elingu-6061 yi-magnesium ne-silicon, futhi zakha isigaba se-Mg2Si. Uma iqukethe inani elithile le-manganese ne-chromium, inganciphisa umphumela omubi wensimbi; ngezinye izikhathi inani elincane lethusi noma i-zinc liyangezwa ukuthuthukisa ubulukhuni be-alloy.

Amandla ngaphandle kokunciphisa kakhulu ukumelana kwayo nokugqwala; kukhona inani elincane lethusi ezintweni eziqhubayo ukuze kulungiswe imiphumela emibi ye-titanium nensimbi ekuqhubeni; i-aluminium noma i-titanium ingacwengisisa okusanhlamvu futhi ilawule isakhiwo sokuphinda kusetshenziswe;

Ukuze kuthuthukiswe ukusebenza kahle kwemishini, i-lead kanye ne-bismuth kungangezwa. Isixazululo esiqinile se-Mg2Si ku-aluminium senza i-alloy ibe nomsebenzi wokuqina kokuguga okwenziwe.

I-6061-T651 iyinhlanganisela eyinhloko yengxube ye-6061. Ingumkhiqizo wengxube ye-aluminium esezingeni eliphezulu okhiqizwa ngokwelashwa kokushisa kanye nenqubo yokunwebeka ngaphambi kokwelula. Nakuba amandla ayo engenakuqhathaniswa nochungechunge lwe-2XXX noma lwe-7XXX, ingxube yayo ye-magnesium ne-silicon ikhethekile.

Inezakhiwo eziningi, ukusebenza kahle kakhulu kokucubungula, izici ezinhle kakhulu zokushisela kanye nezakhiwo ze-electroplating, ukumelana okuhle kokugqwala, ukuqina okuphezulu kanye nokungaguquguquki ngemva kokucubungula, izinto ezixineneyo ezingenamaphutha futhi kulula ukuzipholisha, kulula ukufaka ifilimu yombala, umphumela omuhle kakhulu wokuxova kanye nezinye izici ezinhle kakhulu.

4, Ishadi lokugeleza kokukhiqizwa kwesitimela:

Ukuncibilikisa → ukuphotha → izinduku zokusaha → izinduku ze-aluminiyamu ezihlanganisa i-homogenizing → ukupholisa, izinduku zokuwasha → izinduku ze-aluminiyamu zingene endlini yokugcina impahla.

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, bese kuthi imali esele ibe yi-B/L. EXW, FOB, CFR, CIF.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.