Izesekeli Zesakhiwo Sensimbi YaseYurophu EN 10025 S275JR Isitebhisi Sensimbi

Imininingwane Yomkhiqizo

| Ipharamitha | Imininingwane / Imininingwane |

|---|---|

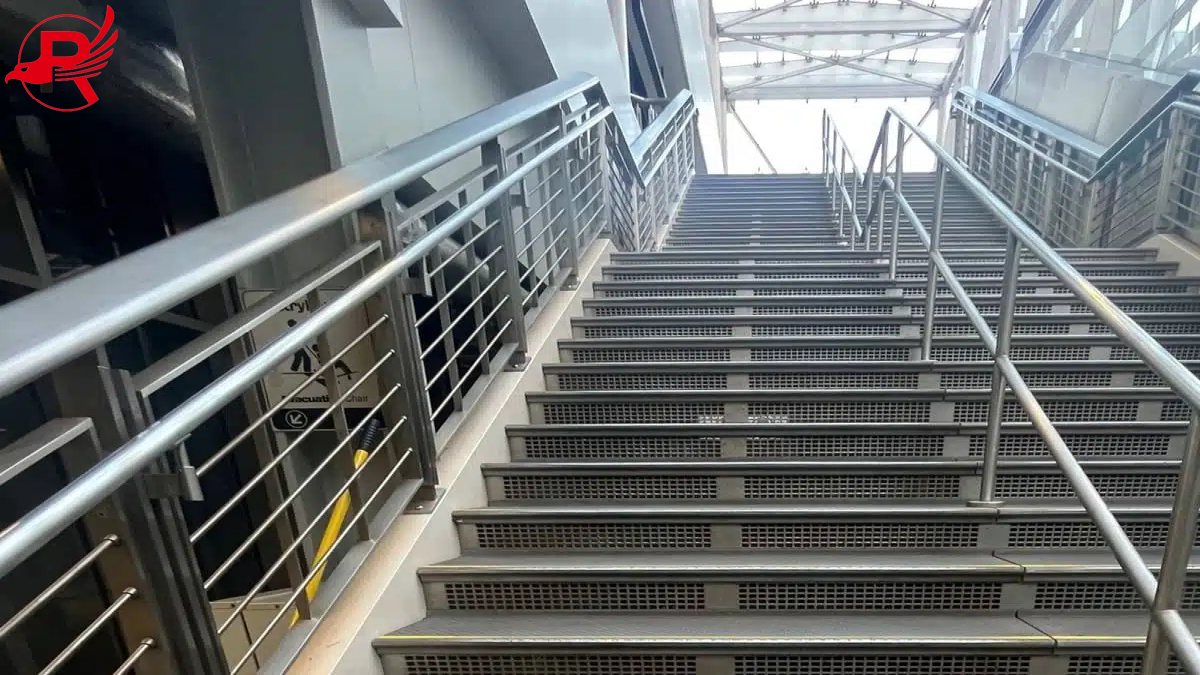

| Igama Lomkhiqizo | Izitebhisi Zensimbi ze-EN 10025 S275JR / Izendlalelo Zensimbi Zesakhiwo Zokusetshenziswa Kwezimboni Nezentengiselwano |

| Izinto | Insimbi Yesakhiwo ye-S275JR |

| Amazinga | I-EN 10025 (Izinga laseYurophu) |

| Ubukhulu | Ububanzi: 600–1200 mm (kungenziwa ngezifiso) Ukuphakama/Ukuphakama: 150–200 mm ngesinyathelo ngasinye Ukujula Kwezinyathelo/Ukuhamba: 250–300 mm Ubude: 1–6 m ngesigaba ngasinye (kungenziwa ngezifiso) |

| Uhlobo | Izitebhisi Zensimbi Ezilungisiwe / Ezihlanganisiwe |

| Ukwelashwa Okuphezulu | I-hot-dip galvanized; ukupenda noma i-powder coating ongazikhethela; i-anti-slip tread iyatholakala |

| Izakhiwo Zemishini | Amandla Okukhiqiza: ≥275 MPa Amandla Okudonsa: 430–580 MPa Ukushibilika okuhle kakhulu nokuqina |

| Izici kanye nezinzuzo | Insimbi yesakhiwo enamandla aphezulu; ukusebenza okuzinzile kwemishini; idizayini ye-modular yokufaka okusheshayo; ifanele ukusetshenziswa ngaphakathi nangaphandle; ubukhulu kanye nezesekeli ezingenziwa ngezifiso ngokugcwele |

| Izicelo | Amafektri, izindawo zokugcina impahla, izakhiwo zebhizinisi, amapulatifomu omphakathi, ama-mezzanine, izitebhisi zokufinyelela, izindawo zokulungisa imishini, izikhungo zokucubungula |

| Isitifiketi Sekhwalithi | I-ISO 9001 |

| Imigomo Yokukhokha | Ibhalansi ye-T/T engu-30% kusengaphambili + engu-70% |

| Isikhathi sokuthumela | Izinsuku ezingu-7–15 |

Usayizi Wezitebhisi Zensimbi ze-EN 10025 S275JR

| Ingxenye Yezitebhisi | Ububanzi (mm) | Ukuphakama/Ukuphakama Ngesinyathelo Ngasinye (mm) | Ukujula Kwesinyathelo/Unyawo (mm) | Ubude ngeSigaba ngasinye (m) |

|---|---|---|---|---|

| Isigaba Esijwayelekile | 600 | 150 | 250 | 1–6 |

| Isigaba Esijwayelekile | 800 | 160 | 260 | 1–6 |

| Isigaba Esijwayelekile | 900 | 170 | 270 | 1–6 |

| Isigaba Esijwayelekile | 1000 | 180 | 280 | 1–6 |

| Isigaba Esijwayelekile | 1200 | 200 | 300 | 1–6 |

Okuqukethwe Kwezitebhisi Zensimbi ze-EN 10025 S275JR

| Isigaba Sokwenza Ngokwezifiso | Izinketho Ezitholakalayo | Incazelo / Ububanzi |

|---|---|---|

| Ubukhulu | Ububanzi, Ukuphakama Kwezinyathelo, Ukujula Kokunyathela, Ubude Bezitebhisi | Ububanzi: 600–1500 mm; Ukuphakama Kwezinyathelo: 150–200 mm; Ukujula Kokunyathela: 250–350 mm; Ubude: 1–6 m ngesigaba (kulungiselelwa izidingo zephrojekthi) |

| Ukucubungula | Ukubhoboza, Ukusika, Ukushisela, Ukufakwa Kwezinsika/Izinsika Zokuvikela | Izinti zokubopha kanye nezintambo zingabholwa noma zisikwe ngokwezidingo; ukushisela okwenziwe kusengaphambili kuyatholakala; izibambo zokubopha kanye nezithiyo zokuvikela zingafakwa efektri |

| Ukwelashwa Okuphezulu | Ukufaka i-hot-dip galvanizing, Ukupenda kwezimboni, Ukufaka i-powder, Ukufaka i-anti-slip | Ukuqeda umphezulu kukhethwe ngokusekelwe ezidingweni zemvelo zangaphakathi, zangaphandle, noma zasogwini ukuze kuvikelwe ukugqwala nokushelela |

| Ukumaka Nokupakisha | Amalebula enziwe ngokwezifiso, Ukubhala ikhodi yephrojekthi, Ukupakisha okuthekelisiwe | Amalebula abonisa ibanga lezinto, ubukhulu, kanye nolwazi lwephrojekthi; ukupakishwa okufanelekela isitsha, umbhede osicaba, noma ukulethwa kwendawo |

Ukuqedwa Komphezulu

Izindawo Ezivamile

Izindawo Ezihlanganisiwe

Ingaphezulu Lopende Lokufutha

Isicelo

-

Izakhiwo Zezimboni Nezakhiwo

Ilungele amafektri, izindawo zokugcina impahla, nezinye izikhungo zezimboni, inikeza ukufinyelela okuphephile nokuthembekile ezitezi, amapulatifomu, kanye nemishini ngenkathi isekela umthamo ogcwele womthwalo. -

Izakhiwo zamahhovisi nezitolo

Ifanelekela izitebhisi eziyinhloko noma zesibili emahhovisi, ezindaweni zokuthenga, nasemahhotela, inikeza ikhambi lesimanje, elihlala isikhathi eside, nelinobungani nethrafikhi ephezulu. -

Izicelo Zokuhlala

Ukukhetha okungabizi kakhulu kwezakhiwo zokuhlala ezinezitezi eziningi neziphansi, okungenziwa ngezifiso ngokugcwele ukuze kuhlangatshezwane nemiklamo yezakhiwo kanye nezidingo zephrojekthi ethile, okuhlanganisa izinketho zengilazi kanye nokuqeda.

Izinzuzo Zethu

Insimbi Yesakhiwo Sezindwangu

Kwenziwe ngensimbi ye-EN 10025 S275JR enokucubungula, umthamo omkhulu wokuthwala umthwalo.

Umklamo Ongenziwa Ngokwezifiso

Usayizi wezitebhisi, isikhala sereyili kanye nokuphela kungenziwa ngokwezifiso ukuze kuhambisane nendawo ethile yokwakha, izidingo zephrojekthi.

Ukwakhiwa Kwe-Modular

Izingxenye ezilungisiwe kusengaphambili zokuhlanganisa ngokushesha zinciphisa umsebenzi futhi zicindezele isikhathi sokwakha.

Ukuthobela Ukuphepha

Izindinganiso zokuphepha zezimboni, zezentengiselwano, kanye nezasekhaya zingalandelwa njengezitebhisi ezingasheleli kanye nezinsimbi zokuvikela ezingakhethwa.

Ukuvikelwa Okuthuthukisiwe Komphezulu

Ngokusebenzisa i-hot-dip galvanizing, upende wezimboni noma i-powder coating yendawo yangaphakathi, yangaphandle noma yasolwandle.

Izinhloso Eziningi

Yakhelwe iFektri, iBhizinisi, iNdlu, iSiteshi Sokuthutha, iPort, iPlatform Yokulungisa.

Usekelo Lobuchwepheshe Nolwezokuthutha

Izinsizakalo ze-OEM, njengokwenza ngokwezifiso umklamo, ukupakisha amaphrojekthi kanye nezixazululo zokulethwa eceleni kwekhasimende.

*Thumela i-imeyili ku-[i-imeyili ivikelwe]ukuthola ikhotheshini yamaphrojekthi akho

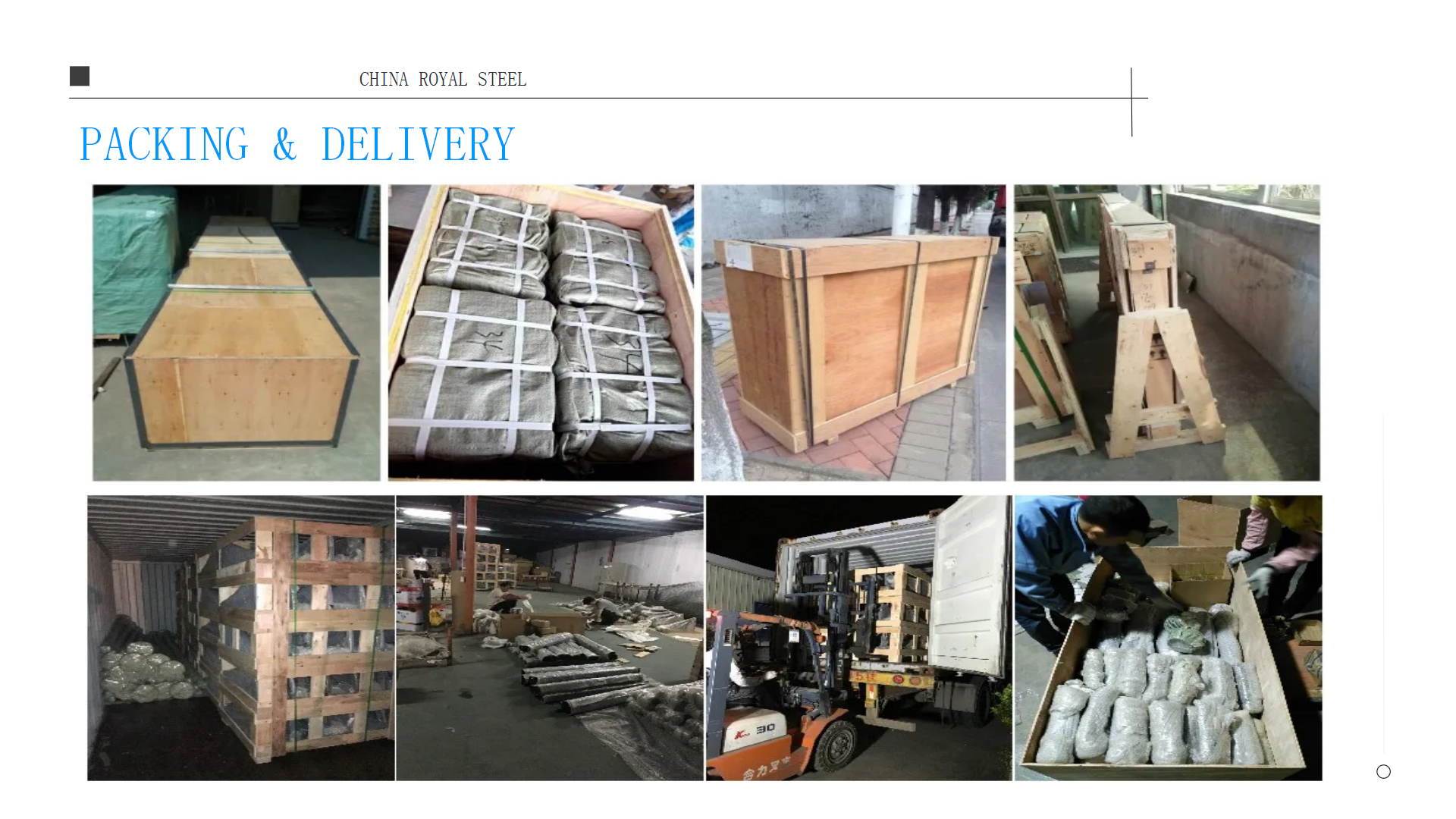

Ukupakisha Nokuthumela

UKUPHAKISHA

Isivikelo: Ukuze kuvikelwe imodyuli, imodyuli ngayinye yezitebhisi isongwe nge-tarpaulin bese ifakwa i-foam noma ibhokisi ezinhlangothini zombili ukuvimbela ukuklwebheka, ukumanzisa noma ukugqwala ngenkathi kuphathwa.

Ukukhumula: Amaqoqo aboshwa ngezintambo zensimbi noma zepulasitiki ukuze azinze ngesikhathi sokulayisha, ukulayisha nokuthutha.

Ukulebula: Ilebula lokuhlonza ukulandelela okubili kwesiNgisi kuya kweSpanishi lifaka ibanga lezinto ezibonakalayo, indinganiso ye-en/astm, usayizi, ireferensi ye-batch kanye nemininingwane yokuhlola/yombiko.

UKULETHWA

Ezokuthutha Emhlabeni: Amaqoqo avikelwe emaphethelweni futhi asongwe ngezinto ezingasheleli ukuze zithunyelwe endaweni yokusebenza endaweni.

Ezokuthutha Ngesitimela: Le ndlela yokulayisha encane ivumela ukuthi kulayishwe izitebhisi eziningi ezinqoleni zesitimela, okunikeza indlela ephumelelayo yokuhamba ibanga elide.

Impahla Yasolwandle: Kuye ngezwe lapho uya khona kanye nohlelo lokuthutha lwephrojekthi, imikhiqizo ingapakishwa esitsheni esijwayelekile noma esivulekile phezulu.

Imibuzo Evame Ukubuzwa

Q1: Izitebhisi zakho zensimbi zenziwe ngezinto zini?

A:Izitebhisi zethu zenziwe ngeI-EN 10025 S275JR insimbi yesakhiwo, enikeza amandla athuthukisiwe, ukuqina, kanye nokuphila kwesikhathi eside kwenkonzo.

Q2: Ingabe izitebhisi zensimbi zingenziwa ngokwezifiso?

A:Yebo, sinikeza ukwenza ngokwezifiso okugcwele, okuhlanganisa ububanzi bezitebhisi, ukuphakama kwesikhuphukeli, ukujula kokuhamba ngezinyawo, ubude obuphelele, izibambo, ukuqedwa kwendawo, kanye nezinye izidingo ezithile zephrojekthi.

Q3: Yiziphi izindlela zokwelapha ezitholakalayo?

A:Izinketho zifaka phakathii-hot-dip galvanizing, i-epoxy coating, i-powder coating, kanye ne-non-slip finishes, ifanele izindawo zangaphakathi, zangaphandle, noma zasogwini.

UMBUZO 4: Izitebhisi zilungiselelwa kanjani ukuthunyelwa?

A:Izitebhisi ziboshwe ngokuqinile, zigoqwe kahle, futhi zilebula ngesiNgisi nangesiSpanishi. Ukulethwa kungahlelwa ngomgwaqo, ngesitimela, noma ngolwandle, kuye ngokuthi iphrojekthi ihlela kanjani kanye nebanga elingakanani.