Futhi Sizokusiza Ukukutholela

Uma ukhetha izinto zokucubungula ukusika, kubalulekile ukucabangela izakhiwo ezithile kanye nezici zezinto, kanye nezidingo zomkhiqizo wokugcina. Nazi ezinye izinto ezijwayelekile okufanele uzicabangele ngokukhetha izinto zokucubungula ukusika:

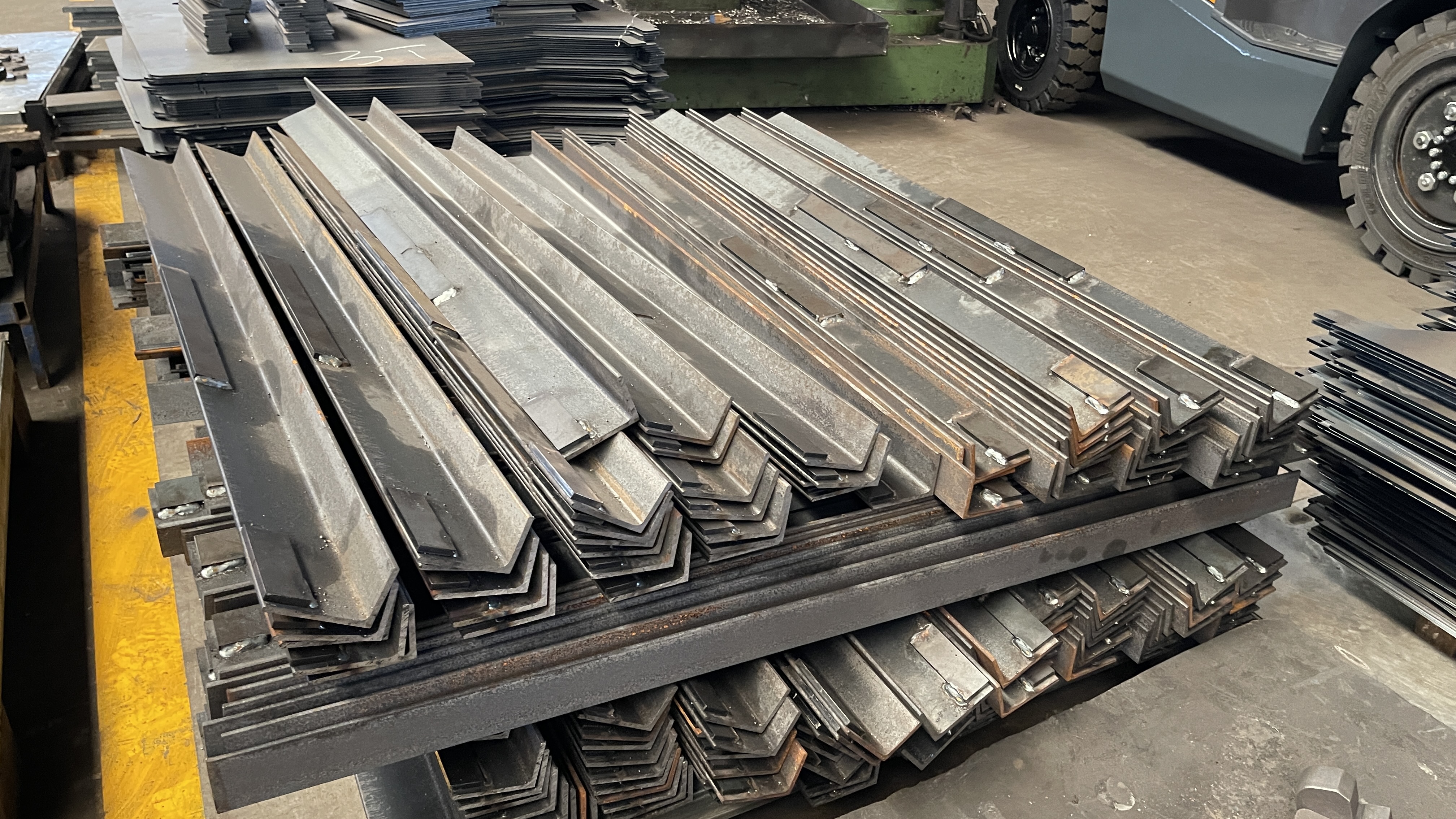

Ubulukhuni: Izinto ezinobulukhuni obuphezulu, njengezinsimbi kanye nepulasitiki eqinile, zingadinga amathuluzi okusika anokumelana nokuguguleka okuphezulu.

Ubukhulu: Ubukhulu bezinto buzothinta ukukhetha indlela yokusika kanye nemishini. Izinto ezijiyile zingadinga amathuluzi noma izindlela zokusika ezinamandla kakhulu.

Ukuzwela kokushisa: Ezinye izinto zizwela ukushisa okukhiqizwa ngesikhathi sokusika, ngakho-ke izindlela ezifana nokusika ngejethi yamanzi noma ukusika nge-laser zingase zikhethwe ukunciphisa izindawo ezithintekile ukushisa.

Uhlobo lwezinto: Izindlela ezahlukene zokusika zingase zifaneleke kakhulu ezintweni ezithile. Isibonelo, ukusika nge-laser kuvame ukusetshenziselwa izinsimbi, kuyilapho ukusika ngejethi yamanzi kufanelekela izinto eziningi ezahlukene okuhlanganisa izinsimbi, ipulasitiki, kanye nezinto ezihlanganisiwe.

Ukuqeda kobuso: Ukuqeda kobuso okufiswayo kwezinto ezisikiwe kungathinta ukukhetha indlela yokusika. Isibonelo, izindlela zokusika ezihudulayo zingase zikhiqize imiphetho eqinile uma kuqhathaniswa nokusika nge-laser.

Ngokucabanga ngalezi zici, abakhiqizi bangakhetha izinto ezifanele kakhulu zokusika ukuze bafinyelele imiphumela efiselekayo.

| Insimbi | Insimbi engagqwali | I-Aluminiyamu Ingxubevange | Ithusi |

| Q235 - F | 201 | 1060 | H62 |

| Q255 | 303 | 6061-T6 / T5 | H65 |

| 16Mn | 304 | 6063 | H68 |

| 12CrMo | 316 | 5052-O | H90 |

| # 45 | 316L | 5083 | C10100 |

| 20 G | 420 | 5754 | C11000 |

| Q195 | 430 | 7075 | C12000 |

| Q345 | 440 | 2A12 | C51100 |

| S235JR | 630 | ||

| S275JR | 904 | ||

| S355JR | 904L | ||

| I-SPCC | 2205 | ||

| 2507 |

Uma ungenaye umklami ochwepheshe ozokukwenzela amafayela okuklama izingxenye zobungcweti, khona-ke singakusiza ngalo msebenzi.

Ungangitshela ugqozi lwakho kanye nemibono noma wenze imidwebo bese singayiguqula ibe yimikhiqizo yangempela.

Sineqembu lonjiniyela abangochwepheshe abazohlaziya umklamo wakho, batuse ukukhethwa kwezinto zokwakha, kanye nokukhiqizwa kokugcina kanye nokuhlanganiswa.

Insizakalo yokusekela ubuchwepheshe etholakala kanye kuphela yenza umsebenzi wakho ube lula futhi ube lula.

Sitshele Okudingayo

Amakhono ethu asivumela ukuthi sakhe izingxenye ngezindlela ezahlukahlukene zokwakheka ngokwezifiso nezitayela, njenge:

- Ukukhiqiza Izingxenye Zezimoto

- Izingxenye Zezindiza

- Izingxenye Zemishini Yemishini

- Izingxenye Zokukhiqiza