Insizakalo Yokushisela Insimbi Yensimbi Eyenziwe Ngokwezifiso Nesevisi Yokusika I-Laser Izingxenye Zokunyathela Ukucutshungulwa Kwensimbi Yeshidi

Imininingwane Yomkhiqizo

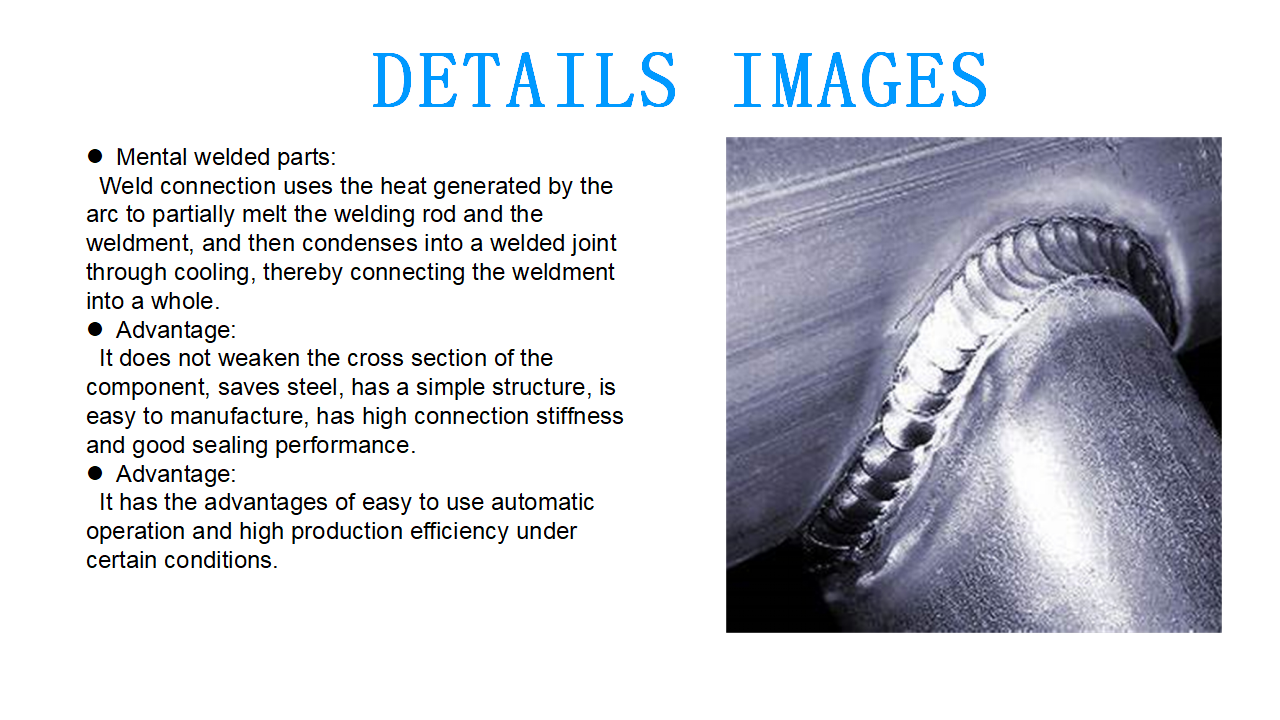

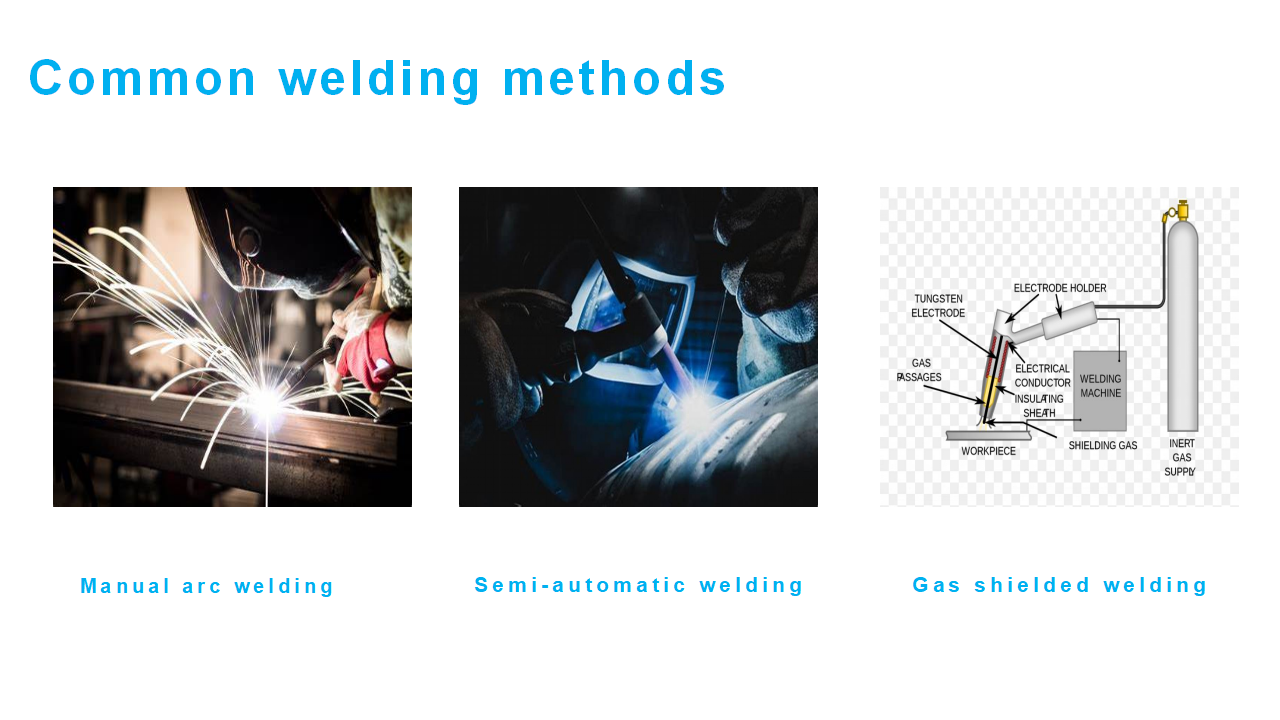

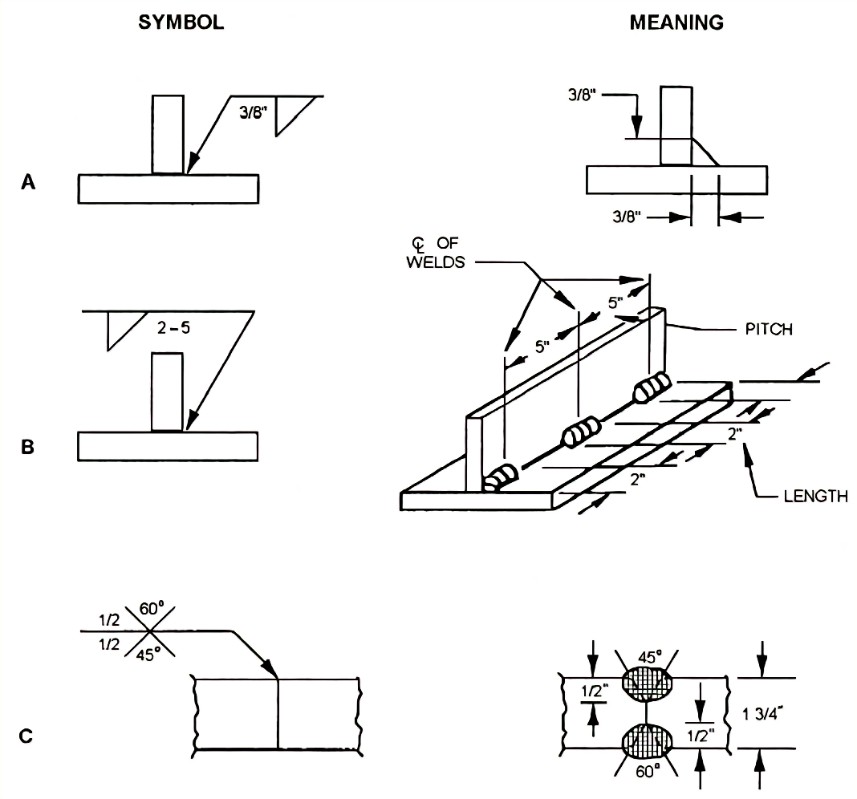

Izindlela ezivamile zokushisela zifaka phakathi ukushisela kwe-arc, ukushisela okuvikelwe ngegesi, ukushisela nge-laser, njll. Ukushisela kwe-arc kungenye yezindlela ezisetshenziswa kakhulu zokushisela. I-arc ikhiqiza izinga lokushisa eliphezulu ukuze incibilikise izinto zokushisela. Ivame ukusetshenziswa ezakhiweni zensimbi, ekwakheni imikhumbi nakwezinye izindawo. Ukushisela okuvikelwe ngegesi kusebenzisa igesi engangeni noma igesi esebenzayo ukuvikela indawo yokushisela ukuvimbela i-oxidation nokunye ukungcola. Ifanele ukushisela i-aluminium alloy, insimbi engagqwali nezinye izinto. Ukushisela nge-laser kusebenzisa imisebe ye-laser enamandla aphezulu ukuncibilikisa nokuhlanganisa izinto zokushisela. Inezinzuzo zokunemba okuphezulu nendawo encane ethintekile ekushiseni, futhi ifanele ukushisela ngokunemba kanye nokukhiqizwa okuzenzakalelayo.

Ukucutshungulwa kokushiselaIdlala indima ebalulekile embonini yokukhiqiza, ivumela ukuxhumana nokulungiswa kwezinto zokwakha, futhi isetshenziswa kabanzi ezindizayo, ekukhiqizeni izimoto, ubunjiniyela bokwakha kanye neminye imikhakha. Ngokuthuthuka okuqhubekayo kobuchwepheshe, ukucubungula ukushisela nakho kusungula izinto ezintsha njalo. Ukusetshenziswa kobuchwepheshe obuphezulu njengoshisela we-laser kanye noshisela we-plasma arc kunikeza izinketho eziningi kanye namathuba embonini yokukhiqiza.

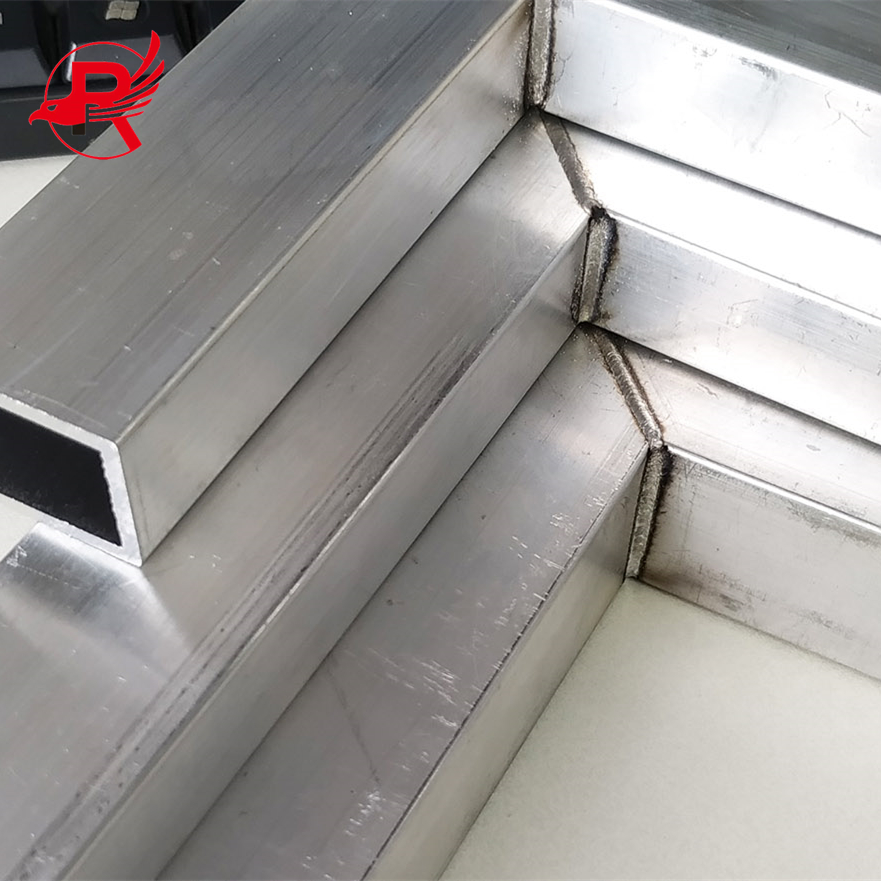

Ezweni lokusebenza ngensimbi, ukwenziwa kwensimbi yokushisela kuyikhono elibalulekile elidinga ukunemba, ubuchwepheshe, kanye neso elibukhali lemininingwane. Kungakhathaliseki ukuthi ukudala imiklamo eyinkimbinkimbi noma ukwakha izakhiwo eziqinile, abenzi bensimbi yokushisela badlala indima ebalulekile ekuletheni insimbi ekuphileni. Kusukela ekushiseni okulungisiwe kuya ekushiseni nge-laser sheet metal, ubuciko bokwenziwa kwensimbi yokushisela buhlanganisa ububanzi bamasu nezinqubo ezibalulekile ezimbonini ezahlukene.

Ukushisela kwekhwalithi kuyitshe lesisekelo lanoma yiliphi ibhizinisi lokushisela eliphumelelayo. Akubandakanyi nje izici zobuchwepheshe zokushisela kodwa futhi nokuzibophezela ekuletheni imiphumela eqinile nengenaphutha. Umenzi wokushisela onekhono uyaqonda ukubaluleka kokusebenzisa izinto zokwakha, imishini, namasu afanele ukuqinisekisa ikhwalithi ephezulu emsebenzini wakhe. Lokhu kuzinikela ekwenzeni kahle kuhlukanisa amabhizinisi okushisela ahloniphekile futhi kuwatholela ukwethenjwa nokwethembeka kwamakhasimende awo.

Uma kukhulunywa ngokuthiishidi lensimbi lokushisela, ukunemba kubalulekile. Ikhono lokuhlanganisa amashidi ensimbi ndawonye ngaphandle kokuphazamiseka lidinga inhlanganisela yobuchwepheshe namathuluzi afanele. I-laser welding sheet metal, ikakhulukazi, isithandwa kakhulu ngenxa yekhono layo lokukhiqiza ama-weld ahlanzekile, anembile anezindawo ezincane ezithinteke kakhulu ekushiseni. Le ndlela ethuthukisiwe ishintshe inqubo yokushisela insimbi, okuvumela ukunemba nokusebenza kahle okukhulu.

Ezweni le-ukwenziwa kokushisela, ukunaka imininingwane kubaluleke kakhulu. Yonke i-weld kumele yenziwe ngokucophelela ukuqinisekisa ubuqotho besakhiwo kanye nobude besikhathi. Kungakhathaliseki ukuthi ukudala ubuciko bensimbi obungokwezifiso noma ukwakha izingxenye zezimboni, ikhono kanye nobuciko bomenzi we-welding kungenza umehluko omkhulu.

Njengoba ubuchwepheshe buqhubeka buthuthuka, ikusasa lokwenziwa kokushisela libukeka lithembisa. Ukusungula izinto ezintsha kanye namasu kuhlala kusunduza imingcele yalokho okungenzeka emhlabeni wokusebenza ngensimbi. Kodwa-ke, into eyodwa ihlala ingaguquki: ukubaluleka kwekhwalithi kanye nokunemba ekwenziweni kokushisela.

Ekuphetheni, ukwenziwa kokushisela kuyinhlanganisela yobuciko nesayensi, lapho ikhono nobuciko kuhlangana khona ukuze kudalwe umsebenzi wensimbi oyingqayizivele. Kusukela ekushiseleni okufekethisiwe kuya ekushiseleni nge-laserishidi lensimbi lokushisela, ukuzinikela ekhwalithini nasekuqondeni kubeka indinganiso yabakhiqizi bokushisela kanye namabhizinisi ngokufanayo. Njengoba imboni iqhubeka nokukhula, ubuciko bokushisela buzoqhubeka nokudlala indima ebalulekile ekubumbeni umhlaba osizungezile.

| Izinto | Insimbi yebhokisi/i-aluminium/ithusi/insimbi engagqwali/i-spcc |

| Umbala | Kwenziwe ngezifiso |

| Ukucubungula | Ukusika nge-laser/Ukushaya nge-CNC/Ukugoba nge-CNC/Ukushisela/Ukupenda/Ukuhlanganisa |

| Ukwelashwa kwendawo | Ukumbozwa kwamandla, i-zinc plated, i-Polishing, i-Plating, i-Brush, isikrini sekhono njll. |

| Ifomethi Yokudweba | I-CAD, i-PDF, i-SOLIDworks njll. |

| Isitifiketi | ISO9001:2008 CE SGS |

| Ukuhlolwa Kwekhwalithi | igeyiji yephini, igeyiji ye-caliper, isivivinyo sokulahla, isivivinyo sokudlidliza, isivivinyo somjikelezo wokuphila komkhiqizo, isivivinyo sokufutha ngosawoti, iphrojektha, ukulinganisa okuhlelekile ama-caliper omshini, i-micro caliper, i-thread miro caliper, i-pass meter, i-pass meter njll. |

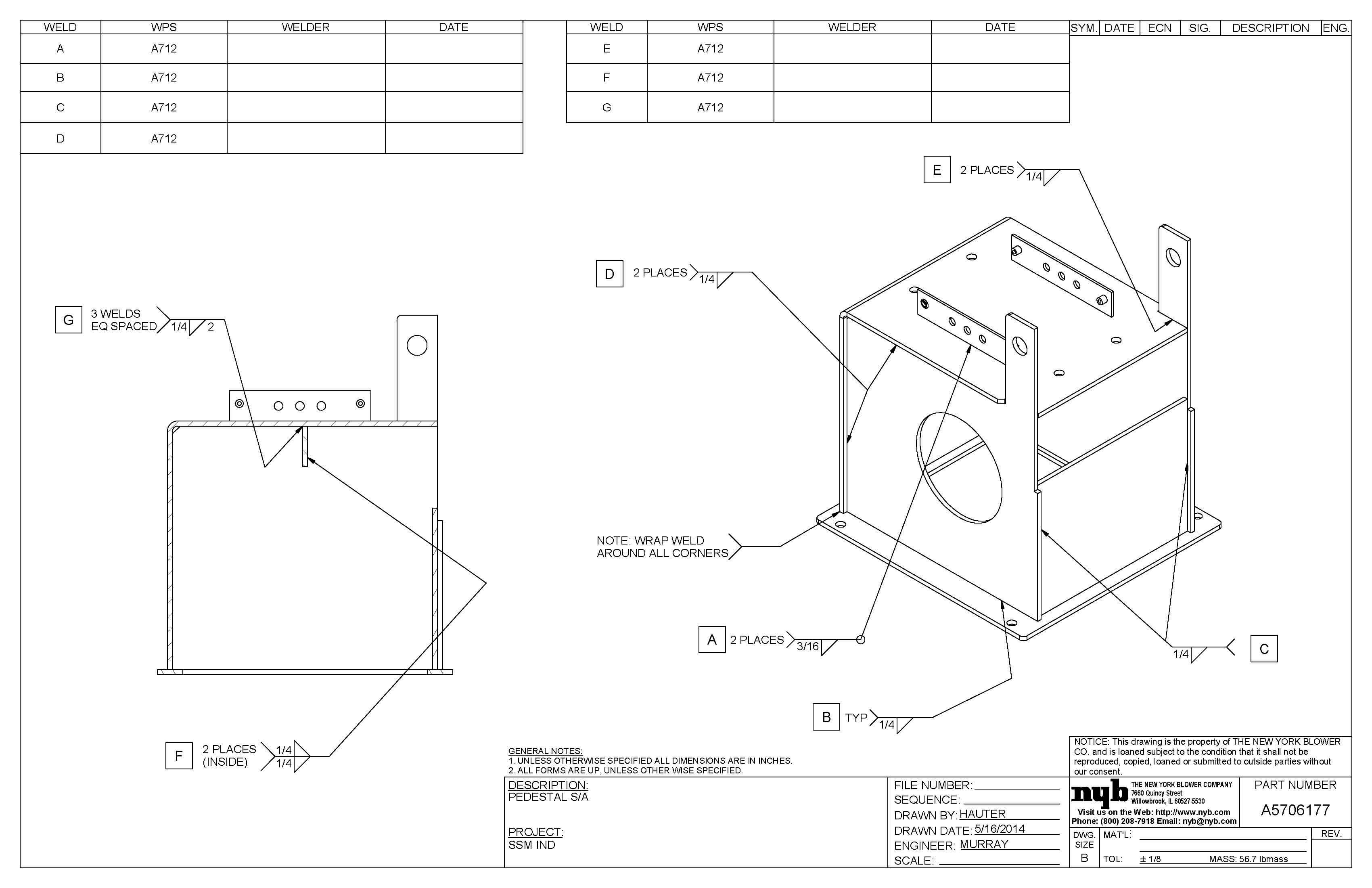

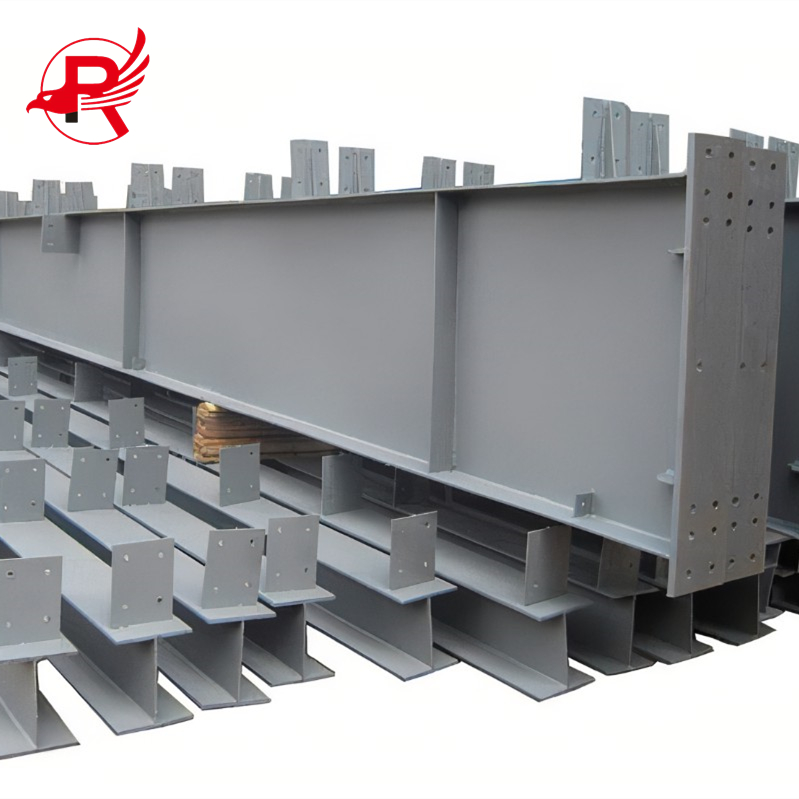

Isibonelo

Lena i-oda esilitholile lokucubungula izingxenye.

Sizokhiqiza ngokunembile ngokwemidwebo.

| Izingxenye Ezifakwe Ngokwezifiso | |

| 1. Usayizi | Kwenziwe ngezifiso |

| 2. Okujwayelekile: | Kwenziwe ngezifiso noma i-GB |

| 3. Izinto | Kwenziwe ngezifiso |

| 4. Indawo yefektri yethu | I-Tianjin, China |

| 5. Ukusetshenziswa: | Hlangana nezidingo zamakhasimende |

| 6. Ukugqoka: | Kwenziwe ngezifiso |

| 7. Inqubo: | Kwenziwe ngezifiso |

| 8. Uhlobo: | Kwenziwe ngezifiso |

| 9. Isimo Sesigaba: | Kwenziwe ngezifiso |

| 10. Ukuhlolwa: | Ukuhlolwa noma ukuhlolwa kweklayenti yiqembu lesithathu. |

| 11. Ukulethwa: | Isitsha, Isitsha Esibanzi. |

| 12. Mayelana Nekhwalithi Yethu: | 1) Akukho monakalo, akukho ukugoba2) Ubukhulu obunembile3) Zonke izimpahla zingahlolwa ngokuhlolwa komuntu wesithathu ngaphambi kokuthunyelwa |

Uma nje unezidingo zokucubungula umkhiqizo wensimbi ezenzelwe wena, singazikhiqiza ngokunembile ngokwemidwebo. Uma kungekho midwebo, abaklami bethu bazokwenzela nemiklamo eyenzelwe wena ngokwezidingo zakho zencazelo yomkhiqizo.

Isibonisi somkhiqizo oqediwe

Ukupakisha Nokuthumela

Iphakheji:

Sizopakisha imikhiqizo ngokwezidingo zamakhasimende, sisebenzisa amabhokisi noma izitsha zokhuni, futhi amaphrofayili amakhulu azopakishwa ngqo ngaphandle kwezimpahla, futhi imikhiqizo izopakishwa ngokwezidingo zamakhasimende.

Ukuthunyelwa:

Khetha indlela efanele yokuhamba: Ngokusho kwenani nesisindo semikhiqizo eyenziwe ngokwezifiso, khetha indlela efanele yokuhamba, njengeloli eliyisicaba, isitsha noma umkhumbi. Cabangela izici ezifana nebanga, isikhathi, izindleko kanye nanoma yiziphi izidingo zomthetho zokuhamba.

Sebenzisa imishini yokuphakamisa efanele: Ukuze ulayishe futhi ukhulule iziteshi ze-strut, sebenzisa imishini yokuphakamisa efanele njenge-crane, i-forklift, noma i-loader. Qiniseka ukuthi imishini esetshenziswayo inomthamo owanele wokuphatha ngokuphephile isisindo sezinqwaba zamashidi.

Ukuvikela Imithwalo: Vikela kahle izinqwaba zemikhiqizo eyenziwe ngokwezifiso ezimotweni zokuthutha usebenzisa izintambo, izibopho, noma ezinye izindlela ezifanele ukuvimbela ukungqubuzana noma ukulimala ngesikhathi sokuthuthwa.

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, kanye nokuphumula ngokumelene ne-B/L.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.