Isevisi Yokusika Iphrofayili Yensimbi Ye-Meta Ngokwezifiso Ukwenziwa Kwensimbi Yeshidi

Imininingwane Yomkhiqizo

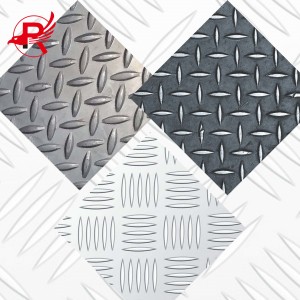

Izingxenye zensimbi zenziwe ngensimbi eluhlaza. Ngokusekelwe kwimidwebo yamakhasimende, senza ngokwezifiso futhi sakha isikhunta ngokusekelwe ezinhlotsheni ezidingekayo, ubukhulu, izinto zokwakha, kanye nokwelashwa kwendawo. Siletha ukukhiqizwa okunembile, kwekhwalithi ephezulu, kanye nobuchwepheshe obuphezulu okufanela izidingo zakho. Ngisho noma ungenawo umdwebo womklamo, abaklami bethu bazowuklama ngokwezidingo zakho.

Izinhlobo eziyinhloko zezingxenye ezicutshunguliwe:

izingxenye ezishisiwe, imikhiqizo enezimbobo, izingxenye ezimboziwe, izingxenye ezigobile, izingxenye zokusika

Ukusika i-plasma kusetshenziswa kabanzi ekusebenzeni ngensimbi, ekukhiqizeni imishini, ezindizayo, nakweminye imikhakha. Emsebenzini wensimbi, ukusika i-plasma kungasetshenziswa ukusika izingxenye zensimbi ezahlukahlukene, njengezingcwecwe zensimbi kanye ne-aluminium alloys, ukuqinisekisa ukunemba kanye nekhwalithi. Ezindizayo, ukusika i-plasma kusetshenziselwa ukusika izingxenye zezindiza, njengezingxenye zenjini kanye nezakhiwo ze-fuselage, ukuqinisekisa ukunemba kanye nokukhanya.

Ngamafuphi, njengobuchwepheshe bokusika obusebenza kahle futhi obunembile, ukusika i-plasma kunamathuba amaningi okusetshenziswa kanye nesidingo semakethe, futhi kuzodlala indima ebalulekile embonini yokukhiqiza yesikhathi esizayo.

Izinzuzo Zokusika Ishidi Lensimbi Nge-Laser Ekukhiqizeni

Ekukhiqizeni, ukunemba nokusebenza kahle kuyizinto ezibalulekile ekukhiqizeni imikhiqizo esezingeni eliphezulu. Ukusikwa kwensimbi nge-laser kwazalelwa ukubhekana nalezi zidingo, okuletha izinzuzo eziningi ezimbonini eziningi. Kusukela ezimotweni kuya ezindiza, kusukela ku-elekthronikhi kuya ekwakheni, ubuchwepheshe bokusika nge-laser bushintshe indlela insimbi ecutshungulwa futhi isetshenziswa ngayo.

Ukusikwa kwensimbi yeshidi nge-laser kudinga ukusetshenziswa kwe-laser enamandla amakhulu ukusika izinto ngokunemba okukhulu. Le nqubo ivumela ukusikwa kwemiklamo nezimo eziyinkimbinkimbi ngenkathi kunciphisa imfucuza yezinto. Ukusikwa kwe-laser kungasika izinsimbi ezahlukahlukene, kufaka phakathi insimbi, i-aluminium, nethusi, okwenza kube yisisombululo esiguquguqukayo sezidingo eziningi zokukhiqiza.

Enye yezinzuzo eziyinhloko zensimbi yokusika nge-laser ukunemba kwayo okuphezulu. Ukunemba kokusika nge-laser kwenza kube nokubekezelelana okuqinile kanye nemininingwane eyinkimbinkimbi, okuholela ekuhlanganisweni okungenamthungo kwezingxenye kanye nokuhlanganiswa. Lokhu kunemba kubalulekile ezimbonini lapho ngisho nokuphambuka okuncane kakhulu kungaholela ezinkingeni ezinkulu ngomkhiqizo wokugcina.

Ngaphezu kwalokho, ukusika nge-laser kunikeza indlela esheshayo nephumelelayo yokucubungula insimbi yothayela kunezindlela zendabuko. Ngenxa yobuchwepheshe be-CNC, imiklamo ingahlelwa futhi isetshenziswe ngesikhathi esincane sokusetha, kunciphisa isikhathi sokuguqula futhi kwandise umkhiqizo. Lokhu kuzuzisa kakhulu izimboni ezidinga ukukhiqizwa okuphezulu.

Ngaphezu kokunemba kwayo nokusebenza kahle, ishidi lokusika nge-laser liphinde linikeze ukonga izindleko zesikhathi eside. Ukunciphisa imfucuza yezinto ezibonakalayo kanye nekhono lokukhiqiza imiklamo eyinkimbinkimbi ngaphandle kwesidingo sokwenza amathuluzi engeziwe kunciphisa izindleko zokukhiqiza zabakhiqizi, okuholela ekongeni jikelele.

Ngaphezu kwalokho, ukuguquguquka kobuchwepheshe bokusika nge-laser kwenza kube lula ukwenza ngokwezifiso kanye nokwenza amaphrothotayipu ngaphandle kwemikhawulo yezindlela zamathuluzi zendabuko. Lokhu kusho ukuthi abakhiqizi bangazivumelanisa ngokushesha nezinguquko zomklamo futhi bakhiqize izingxenye ezincane zezingxenye ezenziwe ngokwezifiso ngaphandle kokufaka izindleko eziphezulu zokusetha.

Ngamafuphi, izinzuzo zensimbi yokusika nge-laser embonini yokukhiqiza azinakuphikwa. Kusukela ekunembeni nasekusebenzeni kahle kuya ekongeni izindleko kanye nokuguquguquka, ubuchwepheshe bokusika nge-laser bube yithuluzi elibalulekile ezimbonini ezifuna izingxenye zensimbi ezisezingeni eliphezulu, ezenziwe ngokwezifiso. Njengoba ubuchwepheshe buqhubeka nokuthuthuka, amandla okusika nge-laser embonini yokukhiqiza azoqhubeka nokukhula, ahlinzeke ngezixazululo ezintsha kakhulu embonini.

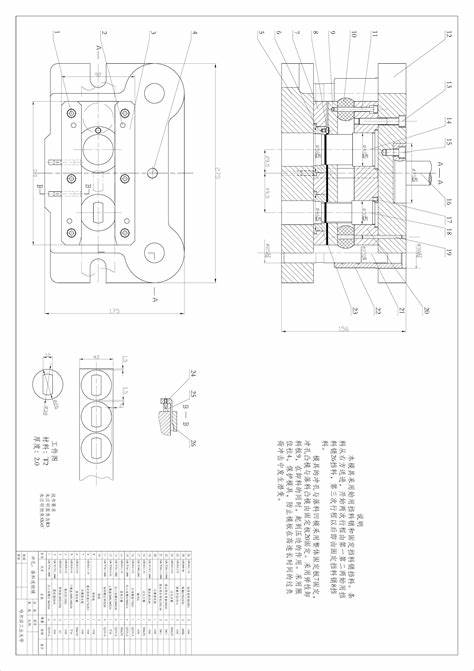

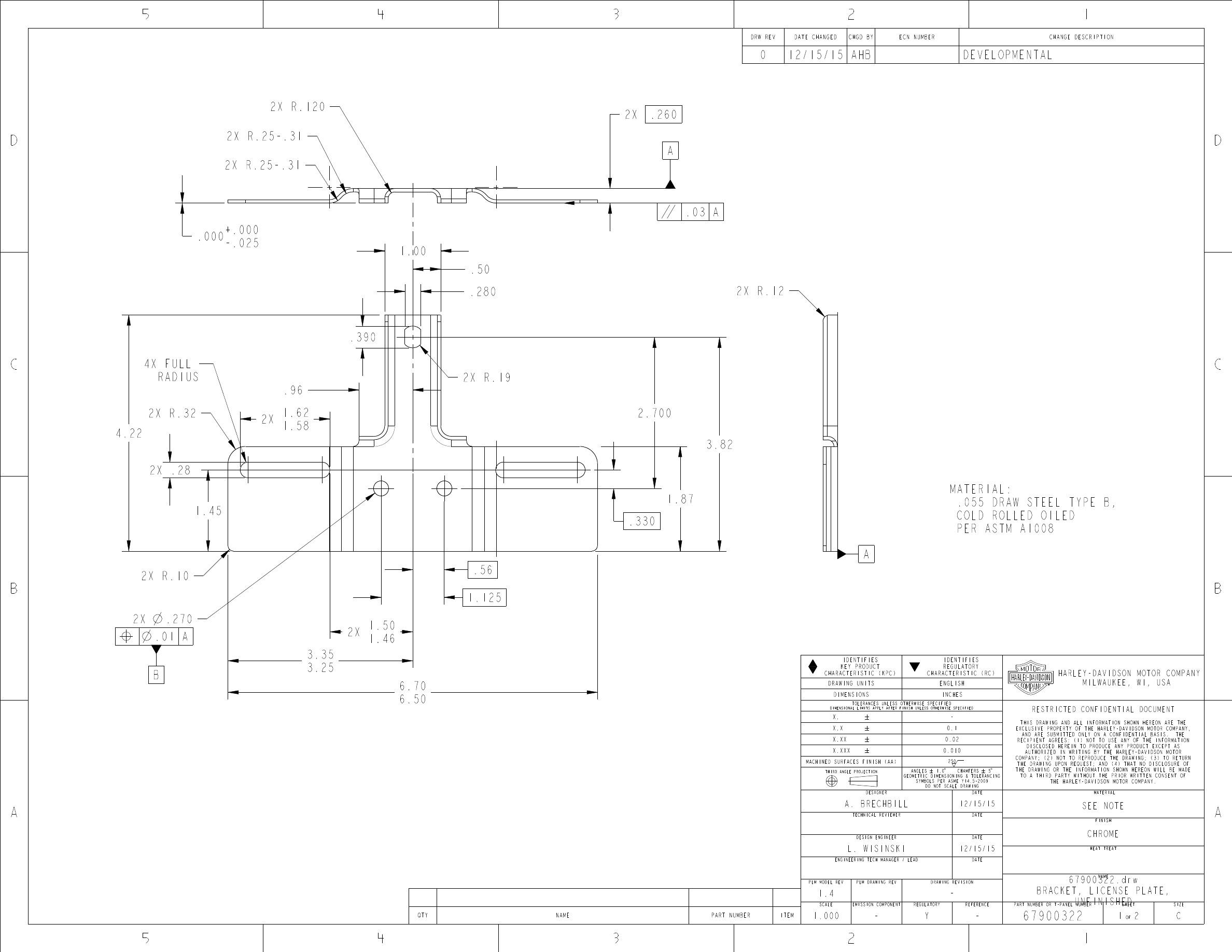

| Izingxenye Zokukhiqiza Ishidi Lensimbi Eliqondile Ngokwezifiso | ||||

| Isilinganiso | Ngokusho komdwebo wakho (usayizi, izinto zokwakha, ukujiya, okuqukethwe kokucubungula, kanye nobuchwepheshe obudingekayo, njll.) | |||

| Izinto | Insimbi yekhabhoni, insimbi engagqwali, i-SPCc, i-SGCc, ipayipi, i-galvanized | |||

| Ukucubungula | Ukusikwa nge-laser, ukugoba, ukugoba, ukubhoboza, ukushisela, ukwakheka kwensimbi, ukuhlanganisa, njll. | |||

| Ukwelashwa Okuphezulu | Ukuxubha, Ukupholisha, Ukufutha, Ukumboza Ngophawuda, Ukucwebezela, | |||

| Ukubekezelelana | '+/-0.2mm, ukuhlolwa kwekhwalithi ye-QC engu-100% ngaphambi kokulethwa, kunganikeza ifomu lokuhlolwa kwekhwalithi | |||

| Ilogo | Ukuphrinta kwesilika, ukumaka nge-laser | |||

| Usayizi/Umbala | Yamukela osayizi/imibala eyenziwe ngokwezifiso | |||

| Ifomethi Yokudweba | .DWG/.DXF/.STEP/.IGS/.3DS/.STL/.SKP/.AI/.PDF/.JPG/.Draft | |||

| Isikhathi Sokufunda Esiyisibonelo | Xoxa ngesikhathi sokulethwa ngokwezidingo zakho | |||

| Ukupakisha | Ngebhokisi/ibhokisi noma ngokwesidingo sakho | |||

| Isitifiketi | I-ISO9001:SGS/TUV/ROHS | |||

Isibonelo

| Izingxenye Ezifakwe Ngokwezifiso | |

| 1. Usayizi | Kwenziwe ngezifiso |

| 2. Okujwayelekile: | Kwenziwe ngezifiso noma i-GB |

| 3. Izinto | Kwenziwe ngezifiso |

| 4. Indawo yefektri yethu | I-Tianjin, China |

| 5. Ukusetshenziswa: | Hlangana nezidingo zamakhasimende |

| 6. Ukugqoka: | Kwenziwe ngezifiso |

| 7. Inqubo: | Kwenziwe ngezifiso |

| 8. Uhlobo: | Kwenziwe ngezifiso |

| 9. Isimo Sesigaba: | Kwenziwe ngezifiso |

| 10. Ukuhlolwa: | Ukuhlolwa noma ukuhlolwa kweklayenti yiqembu lesithathu. |

| 11. Ukulethwa: | Isitsha, Isitsha Esibanzi. |

| 12. Mayelana Nekhwalithi Yethu: | 1) Akukho monakalo, akukho ukugoba 2) Ubukhulu obunembile 3) Zonke izimpahla zingahlolwa ngokuhlolwa komuntu wesithathu ngaphambi kokuthunyelwa |

Isibonisi Somkhiqizo Esiqediwe

Ukupakisha Nokuthumela

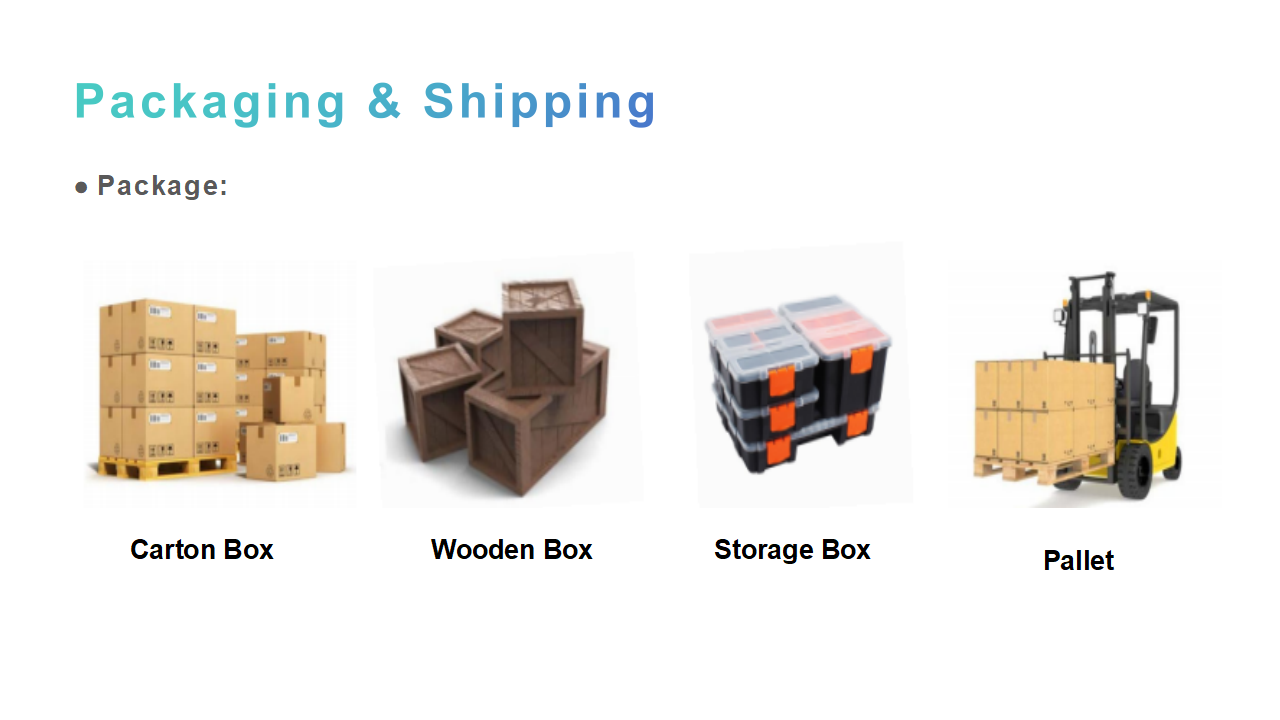

Ukupakishwa nokuthuthwa kwezingxenye ezisikiwe nge-plasma kubalulekile ekuqinisekiseni ikhwalithi yomkhiqizo kanye nokulethwa okuphephile. Okokuqala, ngenxa yokunemba okuphezulu kanye nekhwalithi yezingxenye ezisikiwe nge-plasma, izinto zokupakisha ezifanele kanye nezindlela zibalulekile ukuvimbela umonakalo ngesikhathi sokuthuthwa. Izingxenye ezincane ezisikiwe nge-plasma zingapakishwa emabhokisini e-foam noma emabhokisini. Izingxenye ezinkulu ezisikiwe nge-plasma zivame ukupakishwa emabhokisini ezinkuni ukuze zivikeleke ekulimaleni ngesikhathi sokuthuthwa.

Ngesikhathi senqubo yokupakisha, izingxenye kufanele ziboshwe kahle futhi zifakwe indwangu ngokuvumelana nezici zazo ukuze kuvinjelwe umonakalo ekushayweni nasekudlidlizeni ngesikhathi sokuthuthwa. Ezingxenyeni ezisikiwe nge-plasma ezinezimo ezingavamile, izixazululo zokupakisha ezenziwe ngokwezifiso ziyadingeka ukuqinisekisa ukuqina kwazo ngesikhathi sokuthuthwa.

Ngesikhathi sokuthutha, kubalulekile ukukhetha umlingani wezokuthutha onokwethenjelwa ukuqinisekisa ukulethwa okuphephile nokufika ngesikhathi kwezingxenye ezisikiwe nge-plasma. Ngokuthunyelwa kwamanye amazwe, kubalulekile futhi ukuqonda imithethonqubo yokungenisa efanele kanye nezindinganiso zokuthutha zezwe okuya kulo ukuqinisekisa ukuvunyelwa kwentela kanye nokulethwa okubushelelezi.

Ngaphezu kwalokho, ezingxenyeni ezisikiwe nge-plasma ezenziwe ngezinto ezikhethekile noma ezinezimo eziyinkimbinkimbi, izidingo ezikhethekile njengomswakama nokuvikelwa kokugqwala kumele zicatshangelwe ngesikhathi sokupakisha nokuthuthwa ukuqinisekisa ukuthi ikhwalithi yomkhiqizo ayiphazamiseki.

Ngamafuphi, ukupakishwa nokuthuthwa kwezingxenye ezisikiwe nge-plasma kuyizixhumanisi ezibalulekile ukuqinisekisa ikhwalithi yomkhiqizo kanye nokwaneliseka kwamakhasimende. Kudingeka ukuhlela nokusebenza okunengqondo maqondana nokukhethwa kwezinto zokupakisha, ukugcwaliswa okuqinile, kanye nokukhetha indlela yokuthutha ukuqinisekisa ukuthi imikhiqizo ilethwa kumakhasimende ngokuphephile nangokuphelele.

AMANDLA ENKAMPANI

Kwenziwe eShayina, isevisi yekilasi eliphezulu, ikhwalithi ephezulu, idumile emhlabeni jikelele

1. Umphumela Wesilinganiso: Inkampani yethu inochungechunge olukhulu lokuhlinzeka kanye nefektri enkulu yensimbi, efinyelela imiphumela emikhulu kwezokuthutha kanye nokuthengwa kwempahla, futhi iba yinkampani yensimbi ehlanganisa ukukhiqiza kanye nezinsizakalo.

2. Ukwehlukahluka komkhiqizo: Ukwehlukahluka komkhiqizo, noma iyiphi insimbi oyifunayo ingathengwa kithi, ikakhulukazi ehilelekile ezakhiweni zensimbi, izinsimbi zensimbi, izinqwaba zeshidi lensimbi, amabhulakhethi e-photovoltaic, insimbi yesiteshi, amakhoyili ensimbi ye-silicon neminye imikhiqizo, okwenza kube lula ukukhetha uhlobo lomkhiqizo olufunayo ukuze luhlangabezane nezidingo ezahlukene.

3. Ukunikezwa okuzinzile: Ukuba nomugqa wokukhiqiza ozinzile kanye nochungechunge lokunikezwa kunganikeza ukunikezwa okuthembekile. Lokhu kubaluleke kakhulu kubathengi abadinga insimbi eningi.

4. Ithonya lomkhiqizo: Linethonya lomkhiqizo eliphezulu kanye nemakethe enkulu

5. Isevisi: Inkampani enkulu yensimbi ehlanganisa ukwenza ngokwezifiso, ezokuthutha kanye nokukhiqiza

6. Ukuncintisana kwentengo: intengo enengqondo

UKUVAKASHELA KWAMAKHASIMENDE

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, kanye nokuphumula ngokumelene ne-B/L.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.