Amanani e-China Factory Slotted Strut C Channel Purlins Asezingeni Eliphezulu Amanani Ephaneli Yelanga

Imininingwane Yomkhiqizo

Incazelo: AIsiteshi se-C, eyaziwa nangokuthi i-C-channel, uhlobo lwesiteshi sokwakha insimbi esivame ukusetshenziswa ekwakheni, ekugesi, nasezimbonini. Sinesigaba esinqunyiwe esinomumo ongu-C esinomhlane oyisicaba kanye nemiphetho eqondile ezinhlangothini zombili.

Izinto: Iziteshi ze-C zivame ukwenziwa ngensimbi ehlanganisiwe noma insimbi engagqwali.Iziteshi zensimbi ezihlanganisiwezimbozwe nge-zinc ukuvimbela ukugqwala, kuyilapho iziteshi zensimbi engagqwali zinikeza ukumelana nokugqwala okwandisiwe.

Osayizi: Izingxenye ze-C zitholakala ngobukhulu obuhlukahlukene, okuhlanganisa ubude, ububanzi, kanye nama-gauge. Osayizi abajwayelekile basukela kobukhulu obuncane obuyi-1-5/8" x 1-5/8" kuya kobukhulu obuyi-3" x 1-1/2" noma obuyi-4" x 2".

Izicelo: Izingxenye ze-C zisetshenziswa kakhulu ekusekeleni isakhiwo kanye nokubopha izintambo, amapayipi, nezinye izingxenye. Zisetshenziswa futhi ekufakeni ama-racking, ozimele, kanye nezinhlelo zokusebenza ezahlukahlukene zezimboni.

Ukufakwa: Izisekelo ze-C-section kulula ukuzifaka nokuzixhuma kusetshenziswa izinto ezikhethekile zokufaka, amabhuleki, kanye nama-clamp. Zingafakwa ngezikulufo, ziboshwe ngamabhawodi, noma zishiselwe ezindongeni, ophahleni, noma kwezinye izindawo.

Umthamo Womthwalo: Umthamo womthwalo wezingxenye ze-C uncike kusayizi wazo nezinto ezisetshenziswayo. Abakhiqizi banikeza amashadi omthwalo abonisa umthamo womthwalo onconywayo ophezulu wosayizi ohlukene wohlaka kanye nezindlela zokufaka.

Izesekeli Nezixhumi: Izingxenye ze-C zingafakelwa izesekeli nezixhumanisi ezahlukahlukene, okuhlanganisa ama-spring nuts, ama-beam clamps, izinduku ezinezintambo, ama-hangers, ama-bracket, kanye nezisekeli zamapayipi. Lezi zesekeli zithuthukisa ukuguquguquka kwazo futhi zivumela ukwenza ngezifiso izinhlelo zokusebenza ezithile.

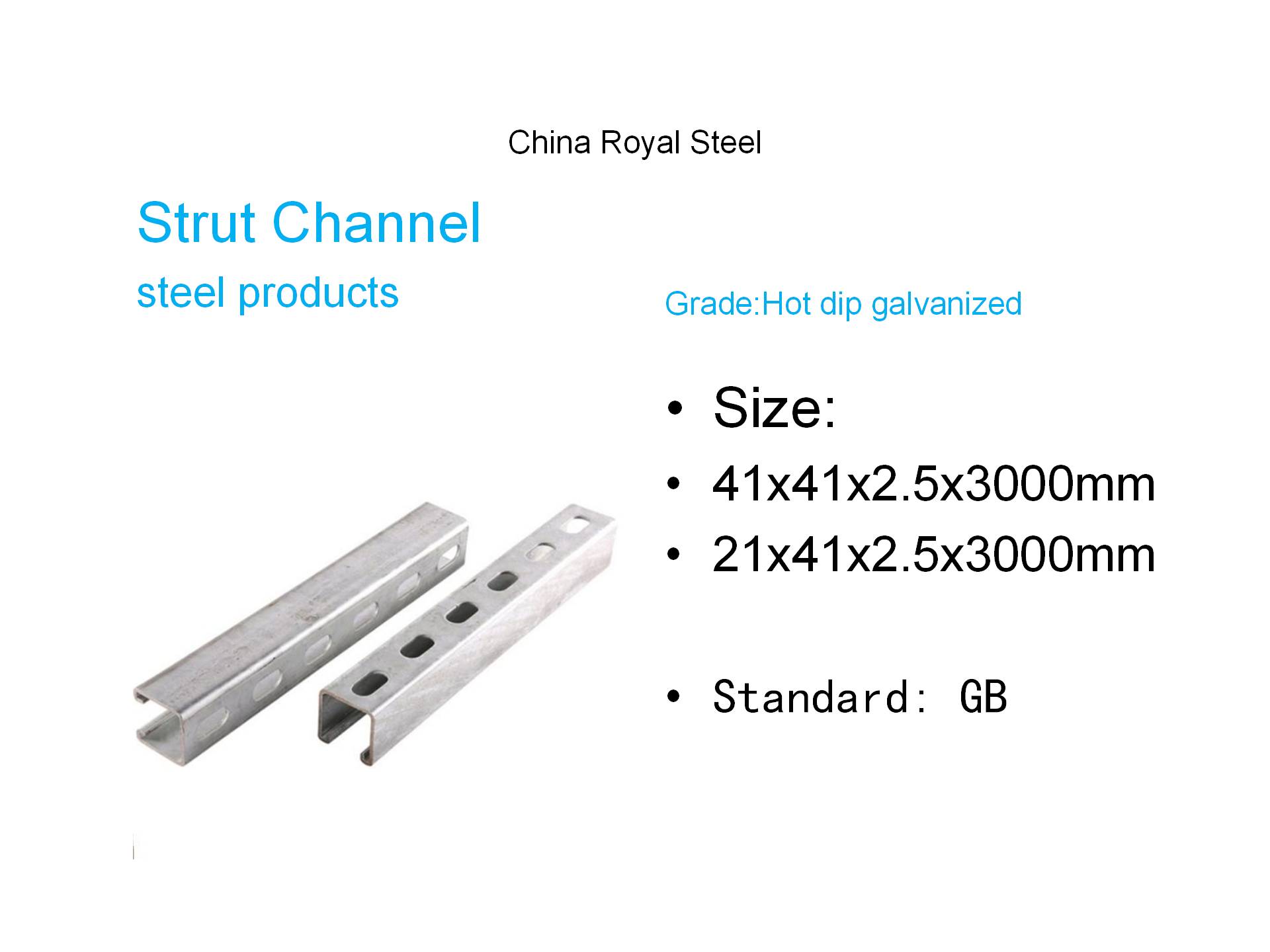

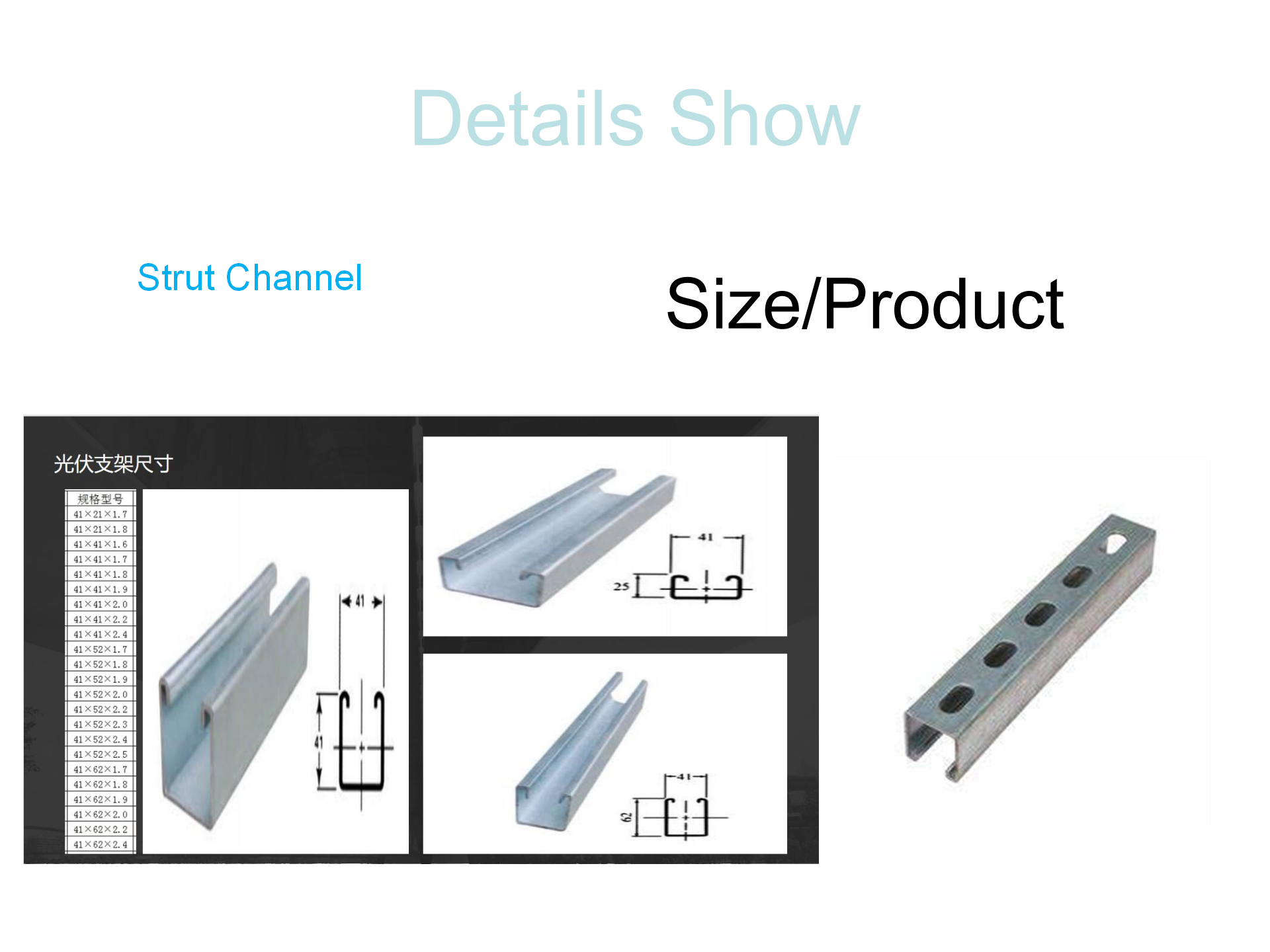

| IZINHLOBO ZOKUCACISAUMGQA O-H | |

| 1. Usayizi | 1) 41x41x2.5x3000mm |

| 2) Ubukhulu beWall: 2mm, 2.5mm, 2.6MM | |

| 3)Isiteshi se-Strut | |

| 2. Okujwayelekile: | GB |

| 3. Izinto | Q235 |

| 4. Indawo yefektri yethu | I-Tianjin, China |

| 5. Ukusetshenziswa: | 1) isitoko esigoqekayo |

| 2) Ukwakha isakhiwo sensimbi | |

| Ithreyi yekhebula engu-3 | |

| 6. Ukugqoka: | 1) i-galvanized2) i-Galvalume 3) i-hot dip ekhanyisiwe |

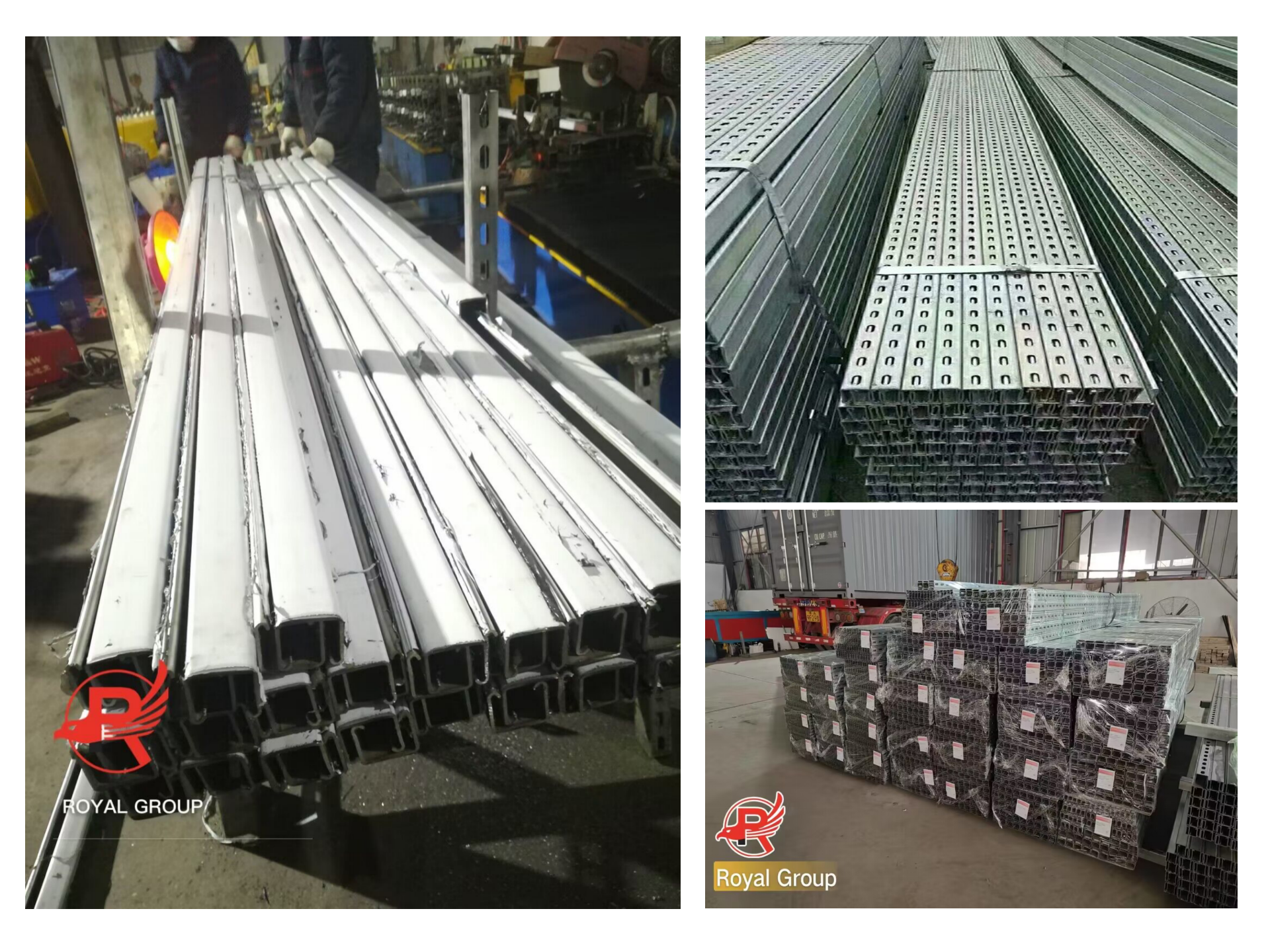

| 7. Inqubo: | hot rolled |

| 8. Uhlobo: | Isiteshi se-Strut |

| 9. Isimo Sesigaba: | c |

| 10. Ukuhlolwa: | Ukuhlolwa noma ukuhlolwa kweklayenti yiqembu lesithathu. |

| 11. Ukulethwa: | Isitsha, Isitsha Esibanzi. |

| 12. Mayelana Nekhwalithi Yethu: | 1) Akukho monakalo, akukho ukugoba 2) Mahhala ukugcotshwa ngamafutha nokumaka 3) Zonke izimpahla zingaphumelela ukuhlolwa komuntu wesithathu ngaphambi kokuthunyelwa |

Izici

Ukuguquguquka: Iziteshi ze-Strut Cingasetshenziswa ezinhlobonhlobo zezicelo, okwenza zibe nezimo ezihlukahlukene ezimbonini ezahlukene njengokwakha, ugesi, kanye nezimboni. Zinikeza ukuguquguquka kokufaka nokusekela izingxenye ezahlukene kanye nengqalasizinda.

Amandla Aphezulu: Umklamo weIphrofayili enomumo we-Cinikeza amandla nokuqina okuhle kakhulu, okuvumela iziteshi ukuthi zisekele imithwalo esindayo futhi zimelane nokugoba noma ukuguquka. Ziyakwazi ukumelana nesisindo samathileyi ekhebula, amapayipi, neminye imishini.

Ukufakwa Okulula: Uhlaka lokusekela lwensimbi oluyi-C lusebenzisa ubukhulu obujwayelekile kanye nezimbobo ezimbozwe kusengaphambili kulo lonke ubude besiteshi, okwenza kube lula inqubo yokufaka kusukela ekuqaleni. Ngezinamathiselo ezifanele, lungafakwa ngokushesha nangokuphephile ezindongeni, ophahleni, noma kwezinye izindawo ngaphandle kwemisebenzi eyinkimbinkimbi, okuthuthukisa kakhulu ukusebenza kahle kokwakha.

Ukulungiswa Okuguquguqukayo: Ukubhoboka okusethwe ngaphambilini esiteshini kunikeza indawo eguquguqukayo yezesekeli nezixhumi ezifana nama-bracket nama-clamp. Kungakhathaliseki ukuthi ukulungisa ukwakheka ukuze kuhlangatshezwane nezidingo zesayithi ngesikhathi sokufakwa noma ukwengeza noma ukususa izingxenye noma ukwenza ngcono ukucushwa ngesikhathi sokuvuselelwa kamuva, konke kungenziwa kalula ngaphandle kokubhoboza kabusha noma ukuguqula isakhiwo esingaphansi, okuhlinzeka ngokuzivumelanisa nezimo okuthuthukisiwe.

Ayimelani Nokugqwala Futhi Ihlala Isikhathi Eside: Yakhiwe ngensimbi ekhanyisiwe noma insimbi engagqwali ekhethwe ngokucophelela, uhlaka lokusekela lwensimbi oluyi-C lunikeza ukumelana okuhle kakhulu nokugqwala. Ngisho nasezindaweni ezinzima ezinomswakama, uthuli, noma izinto ezigqwalisayo, imelana nokugqwala ngempumelelo, igcina ukuqina kwesakhiwo, yandisa kakhulu isikhathi senkonzo, futhi inciphisa izindleko zokulungisa.

Ukuhambisana Okubanzi Kwezesekeli: Uhla oluphelele lwezesekeli ezenzelwe ngqo uhlelo lwesiteshi, kufaka phakathi amantongomane, amabhawodi, ama-clamp, kanye nezixhumi, zihambisana ngokugcwele nohlaka lokusekela lwensimbi oluyi-C. Azikho izingxenye ezengeziwe ze-adaptha ezenziwe ngokwezifiso ezidingekayo; inhlanganisela eguquguqukayo kanye nezinhlanganisela ziyatholakala ngokusekelwe ezidingweni zangempela, okudala kalula uhlelo lokusekela olwenzelwe wena ukuze luhlangabezane nezidingo zezimo ezahlukahlukene.

Ingabizi futhi ingabizi kakhulu: Njengesixazululo esithandwayo sokusekelwa kwesakhiwo nokufakwa, ozimele bokusekela bensimbi obunjwe ngo-C banikeza izindleko eziphansi kunezindlela zokwenza insimbi ngokwezifiso ngenkathi kugcinwa amandla nokuqina kwesakhiwo okuthembekile. Lokhu kuvumela isabelomali sephrojekthi ukuthi silawulwe ngenkathi kuqinisekiswa ikhwalithi nokusebenza kokwakha, kukhulisa ukusebenza kahle kwezindleko.

Isicelo

1. Izakhiwo Zokwakha Nezensimbi

Njengengxenye eyinhloko, yesibili ethwala umthwalo kanye nelungu elisekelayo, insimbi enomfanekiso ka-C idlala indima ebalulekile ezakhiweni zensimbi. Okokuqala, njenge-purlin, ivikela ngokunembile amapuleti ensimbi anombala ophahleni nodonga ngenkathi idlulisela imithwalo ezinsikeni eziyinhloko, iqinisekisa ukuphepha kwesakhiwo. Okwesibili, njengemishayo yodonga, isekela ngempumelelo izinto zodonga, ithuthukisa kakhulu ukumelana kokuguquka kodonga kanye nokuqina okuphelele. Ekwakhiweni kwezindlu ezincane zensimbi ezilula, ukusetshenziswa kwayo kuye kwandiswa kakhulu. Ingasetshenziswa ngqo njengohlaka lwe-keel, uphahla kanye nama-keel okusekela phansi, ngisho nanjengohlaka lwezindonga zokuhlukanisa zangaphakathi. Ilinganisa kahle izidingo ezimbili zokwakha okulula kanye namandla aphezulu okuthwala umthwalo, ivumelanisa nemibono yokwakha ephumelelayo yezakhiwo zanamuhla ezenziwe kusengaphambili.

2. Ukukhiqiza Imishini Yezimboni Nemishini

Ezimweni zokukhiqiza zezimboni, insimbi enobunjwa obungu-C inikeza izinzuzo ezibalulekile zokusebenza: ingasetshenziswa ukudala izisekelo zemishini, njengozimele bokusekela abasizayo bamathuluzi omshini kanye nemigqa yokukhiqiza, ivikele ngokuphephile izingxenye eziyinhloko njengezimoto kanye namapayipi ukuqinisekisa ukusebenza okuzinzile. Isakhiwo sayo esiyingqayizivele esinemiphetho sivumela ukuthi icutshungulwe ibe yizinqola zokuqondisa imishini, okwenza kube lula ukushelela kwama-pulleys nama-slider, kuhlangatshezwane nezidingo zokudlulisela zemishini yokudlulisa elula. Ingasetshenziswa futhi njengemishayo ye-rack yokugcina, ehlanganiswe namakholomu ukwakha ama-rack ezimboni, ekwazi ukuthwala izimpahla ezincane neziphakathi ngokuzinzile. Isetshenziswa kabanzi ezindaweni zokugcina njengezindawo zokugcina impahla kanye nama-workshop, ithuthukisa ukusebenza kahle kwesitoreji.

3. Ezokuthutha kanye Nezokuthutha

Insimbi enomumo we-C, enezici zayo "ezilula + ukuqina okuphezulu", ihlangabezana nezidingo ezahlukahlukene ezimweni zokuhamba. Ku-chassis yezimoto neloli, isebenza njengezakhiwo ezisizayo (ezifana nozimele bomzimba kanye nemishayo yokusekela i-chassis), inciphisa isisindo semoto iyonke kanye nokusetshenziswa kwamandla ngenkathi ikhulisa ukuqina kwe-chassis futhi iqinisekisa ukuphepha kokushayela. Ngaphakathi kwezitsha, isebenza njengelungu elisekelayo, iqinisa ngempumelelo isakhiwo sesitsha futhi ivimbele imithwalo ukuthi ingonakaliswe yizimbobo kanye nokucindezelwa ngesikhathi sokuhamba. Ezinhlelweni zokuhambisa izinto, isebenza njengokusekela imigqa yokuhambisa, iqinisa ngokuqinile izingxenye ezifana namabhande okuhambisa kanye nama-roller, iqinisekisa ukusebenza okuqhubekayo nokuzinzile kanye nokunciphisa ingozi yokwehluleka kwemishini.

4. Ezolimo kanye Nezindawo Zangaphandle

Njengoba inezici ezihlukile zokukhiqiza kwezolimo kanye nezindawo zangaphandle, insimbi enobunjwa obungu-C ikhombisa ukuzivumelanisa nezimo okuhle kakhulu. Ezindlini zokugcina izithombo zezolimo, isebenza njengemigoqo eseceleni kanye nohlaka lokusekela, ixhuma ngokuqinile ohlakeni oluyinhloko lwendlu yokugcina izithombo futhi iqinise ifilimu yendlu yokugcina izithombo ngenkathi ivikela emoyeni wangaphandle nasemvuleni, iqinisekisa indawo ekhulayo eqinile yezitshalo ngaphakathi. Ezindaweni zemfuyo nezinkukhu, ingasetshenziswa ukwakha ohlaka locingo noma njengezibiyeli zokufaka izitsha zokudla kanye nezinisela amanzi. Ukumelana kwayo nokugqwala kumelana nendawo enomswakama yamapulazi futhi kwandisa impilo yenkonzo yemishini. Ekukhangiseni kwangaphandle, isekela amabhodi okukhangisa nezimpawu, ithwala isisindo samaphaneli ngokuqinile futhi iqinisekisa ukuzinza kwesakhiwo isikhathi eside ezindaweni eziyinkimbinkimbi zangaphandle.

5. Umklamo Wangaphakathi kanye Nezicelo Zomphakathi

Ekuhlobiseni kwangaphakathi kanye nezicelo zokuhlala, insimbi enobunjwa obungu-C ihlangabezana nezidingo ezahlukahlukene ngokuhlanganiswa kwayo kokusebenza kanye nobuhle. Njengezihlanganisi zophahla lwangaphakathi, ihambisana kahle namaphaneli e-gypsum board kanye ne-aluminium gusset, idala kalula izakhiwo zophahla ezibushelelezi nezisicaba ezihambisana nezitayela zokuhlobisa ezahlukahlukene. Njengezinhlaka zokuhlukanisa, isekela ibhodi le-gypsum kanye nebhodi le-calcium silicate, ihlukanisa izikhala zangaphakathi ngendlela eguquguqukayo ngenkathi ilinganisela ukuvikela umsindo kanye namandla esakhiwo. Kuma-balcony nasema-terrace, isebenza njengohlaka lwe-guardrail, iqinisa izindonga zengilazi noma zensimbi. Lokhu akugcini nje ngokuhlangabezana nezidingo zokuphepha kodwa futhi kuthuthukisa ubuhle bendawo yonke, kuhambisana nobuhle bekhaya lanamuhla.

Ukupakisha Nokuthumela

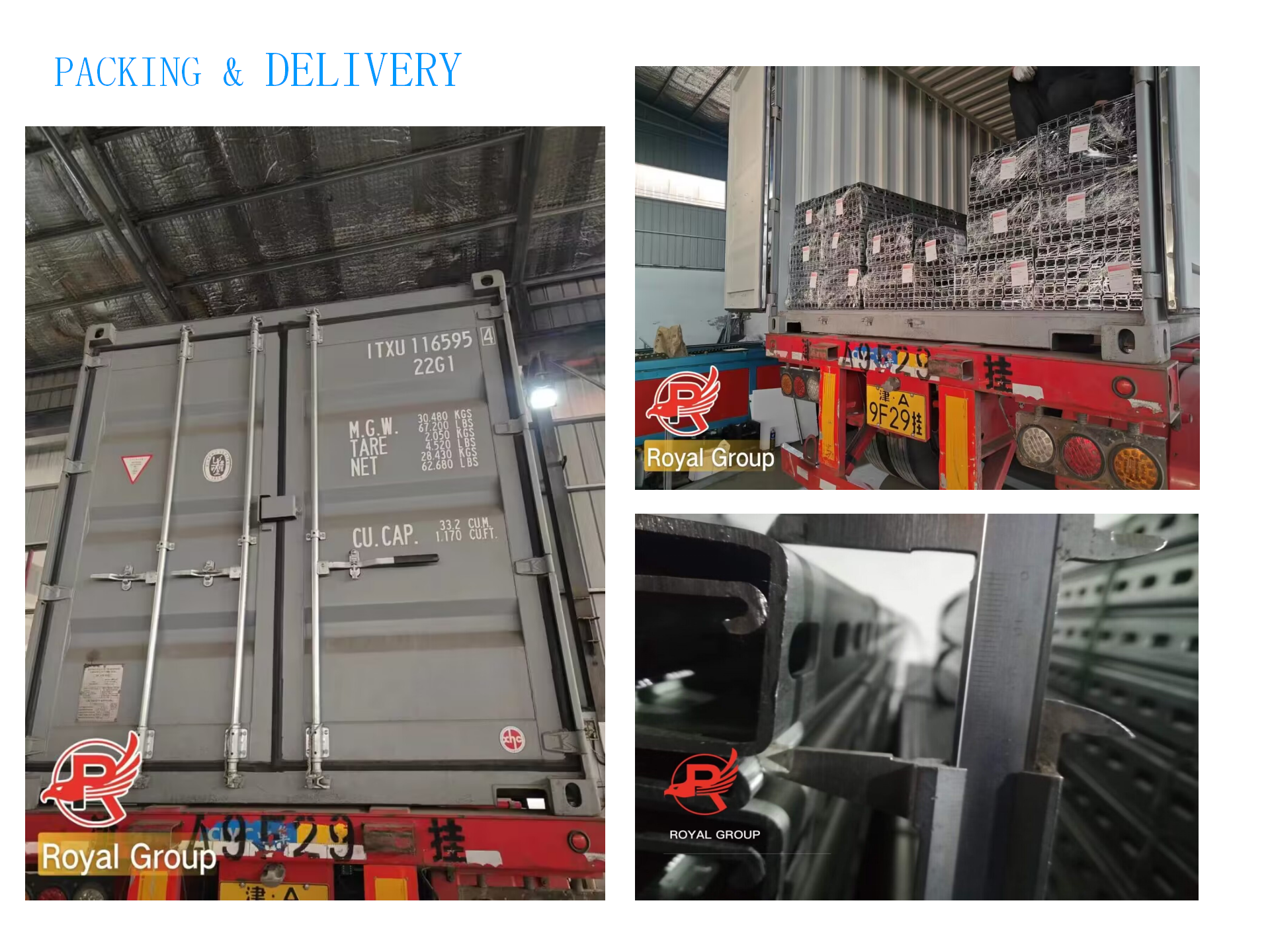

Ukupakisha:

Imikhiqizo yethu ipakishwe ngamabhele. Ibhele ngalinye linesisindo esingu-500-600 kg. Isitsha esincane sinesisindo samathani angu-19. Amabhele asongwe ngepulasitiki.

Ezokuthutha:

Ukukhetha indlela yokuthutha efanele: Ngokusekelwe enanini kanye nesisindo seziteshi zokusekela, khetha indlela yokuthutha efanele, njengeloli eliyisicaba, isitsha, noma umkhumbi. Cabangela izici ezifana nebanga, isikhathi, izindleko, kanye nemithethonqubo yokuthutha efanele ngesikhathi sokuthutha.

Ukusebenzisa imishini yokuphakamisa efanele: Uma ulayisha futhi uthulula iziteshi zokusekela, sebenzisa imishini yokuphakamisa efanele, njenge-crane, i-forklift, noma i-loader. Qinisekisa ukuthi imishini inomthamo owanele wokuthwala umthwalo ukuze isekele ngokuphephile isisindo sezinqwaba zensimbi.

Ukuvikela Umthwalo: Bopha inqwaba yesiteshi sokusekela esipakishiwe emotweni yokuthutha usebenzisa izintambo, izinsimbi zokubopha, noma ezinye izindlela ezifanele zokuyivimbela ukuthi ingashibiliki, ishelele, noma iwe ngesikhathi sokuthutha.

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, bese kuthi imali esele ibe yi-B/L. EXW, FOB, CFR, CIF.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.