I-ASTM Elinganayo Yensimbi Yekhabhoni Yensimbi Ethambile Yekona Yensimbi Ethambile

Imininingwane Yomkhiqizo

I-engeli yensimbi yekhabhoniimigoqo iwuhlobo oluvamile lwensimbi yokwakha esetshenziselwa izinhlelo ezahlukene zokwakha nokukhiqiza. Ngokuvamile yenziwe ngensimbi yekhabhoni, enikeza amandla nokwakheka okuhle. Nazi ezinye zemininingwane ejwayelekile mayelana nemigoqo ye-angle yensimbi yekhabhoni:

Izinto: Amabha e-angle ensimbi yekhabhoni ngokuvamile enziwa ngensimbi yekhabhoni ephansi, equkethe inani elincane lekhabhoni, ngokuvamile aphakathi kuka-0.05% kuya ku-0.25%. Lokhu kuwenza afaneleke ukushisela, ukwakha, kanye nokulungisa.

Isimo: Ama-angle bars ensimbi yekhabhoni ane-cross-section emise okwe-L. Akhiwa ngokugoba ucezu olulodwa lwensimbi nge-engeli engama-degree angu-90, okuholela emilenzeni emibili enobude obulinganayo noma obungalingani.

Ubukhulu: Amabha e-angle ensimbi yekhabhoni atholakala ngezilinganiso ezahlukene ezijwayelekile, okuhlanganisa ubude bemilenze, ukujiya, nobubanzi (kulinganiswa kusukela emaphethelweni angaphandle komlenze owodwa kuya emaphethelweni angaphandle komunye).

Ukuqeda kobuso: Zinganikezwa ngomshini wokugaya, ongase ube nokungapheleli okungaphezulu, noma ngomshini wokuqeda obushelelezi, ocwebezelayo.

Izicelo: Imigoqo ye-angle yensimbi yekhabhoni ivame ukusetshenziswa ezicelweni zesakhiwo nezokwakha, okuhlanganisa ozimele besakhiwo, ukusekela, izisekelo, kanye nokuqinisa. Isetshenziswa futhi ezicelweni zezimboni nezemishini.

Amazinga: Amabha e-angle ensimbi yekhabhoni akhiqizwa ukuze ahlangabezane nezindinganiso ezahlukahlukene zomhlaba wonke, njenge-ASTM, JIS, EN, kanye ne-GB/T.

| Okujwayelekile | I-AISI, i-ASTM, i-DIN, i-GB, i-JIS, i-SUS | |||

| Ububanzi | 2mm kuya ku-400 mm noma 1/8" kuya ku-15" noma njengemfuneko yekhasimende | |||

| Ubude | Amamitha angu-1 kuya kwangu-6 noma njengemfuneko yamakhasimende | |||

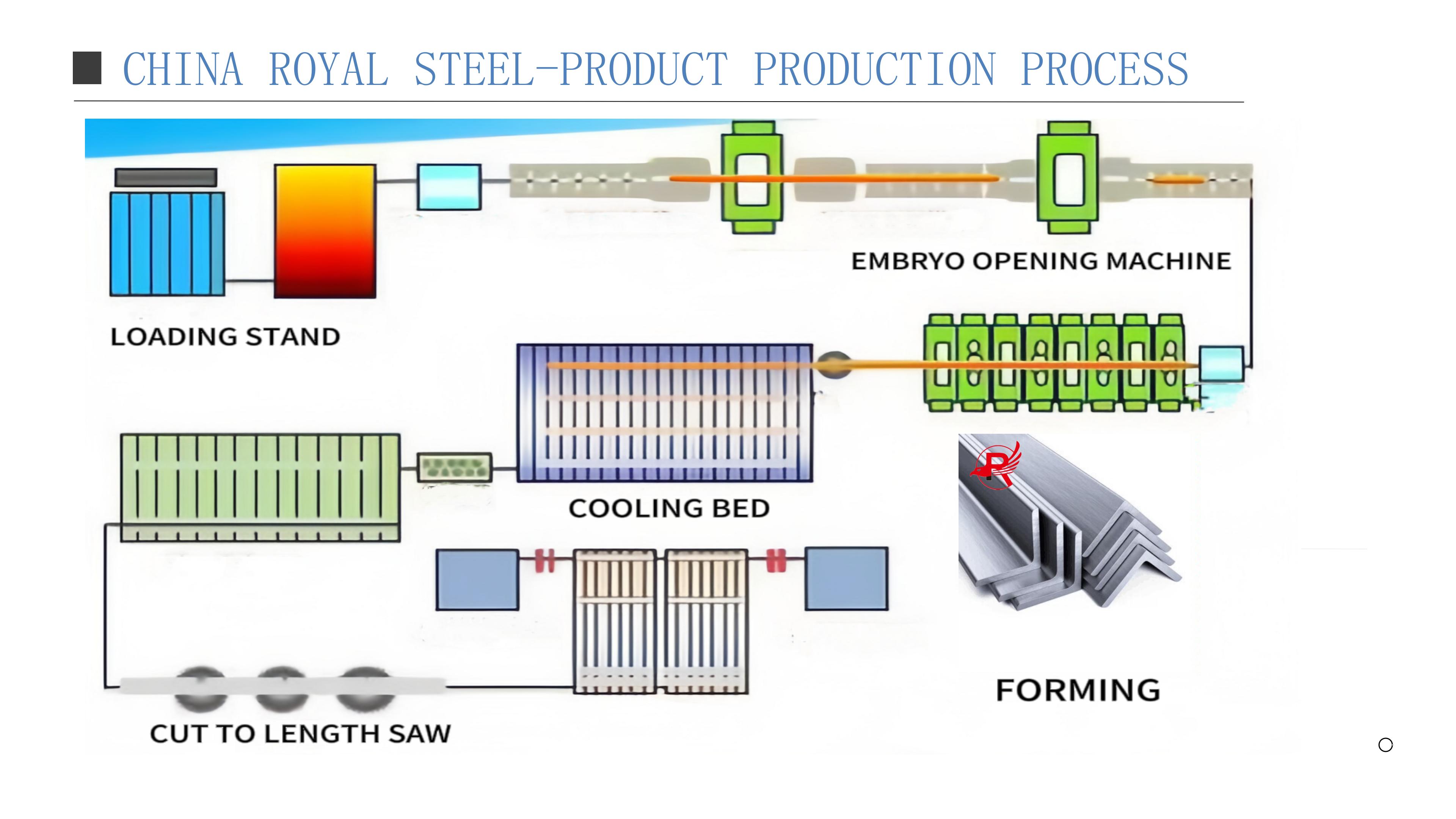

| Ukwelashwa/Indlela Yokusebenza | I-hot rolled, idonswe kubanda, i-Annealed, i-Grinding | |||

| Ubuso | I-Satin, 400#, 600~1000# isibukox, i-HL ebhulashiwe, isibuko esibhulashiwe (izinhlobo ezimbili zokuqeda ipayipi elilodwa) | |||

| Izicelo | Uphethiloli, izinto zikagesi, amakhemikhali, imithi, izindwangu, ukudla, imishini, ukwakhiwa, amandla enuzi, izindiza, ezempi kanye eminye imikhakha | |||

| Imigomo Yokuhweba | I-EXW, i-FOB, i-CFR, i-CIF | |||

| Isikhathi sokuthumela | Kuthunyelwe ezinsukwini eziyi-7-15 ngemuva kokukhokha | |||

| Iphakheji | Iphakheji ejwayelekile efanelekela ulwandle noma njengoba kudingeka | |||

| UKUPHAKISHA OKUFANELEKILE OLWANDLE | I-GP engu-20ft: 5.8m (ubude) x 2.13m (ububanzi) x 2.18m (ukuphakama) cishe 24-26CBM | |||

| I-GP engu-40ft: 11.8m (ubude) x 2.13m (ububanzi) x 2.18m (ukuphakama) cishe 54CBM 40ft HG: 11.8m (ubude) x 2.13m (ububanzi) x 2.72m (ukuphakama) cishe 68CBM | ||||

| Insimbi elingana ne-engeli | |||||||

| Usayizi | Isisindo | Usayizi | Isisindo | Usayizi | Isisindo | Usayizi | Isisindo |

| (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) |

| 20*3 | 0.889 | 56*3 | 2.648 | 80*7 | 8.525 | 12*10 | 19.133 |

| 20*4 | 1.145 | 56*4 | 3.489 | 80*8 | 9.658 | 125*12 | 22.696 |

| 25*3 | 1.124 | 56*5 | 4.337 | 80*10 | 11.874 | 12*14 | 26.193 |

| 25*4 | 1.459 | 56*6 | 5.168 | 90*6 | 8.35 | 140*10 | 21.488 |

| 30*3 | 1.373 | 63*4 | 3.907 | 90*7 | 9.656 | 140*12 | 25.522 |

| 30*4 | 1.786 | 63*5 | 4.822 | 90*8 | 10.946 | 140*14 | 29.49 |

| 36*3 | 1.656 | 63*6 | 5.721 | 90*10 | 13.476 | 140*16 | 33.393 |

| 36*4 | 2.163 | 63*8 | 7.469 | 90*12 | 15.94 | 160*10 | 24.729 |

| 36*5 | 2.654 | 63*10 | 9.151 | 100*6 | 9.366 | 160*12 | 29.391 |

| 40*2.5 | 2.306 | 70*4 | 4.372 | 100*7 | 10.83 | 160*14 | 33.987 |

| 40*3 | 1.852 | 70*5 | 5.697 | 100*8 | 12.276 | 160*16 | 38.518 |

| 40*4 | 2.422 | 70*6 | 6.406 | 100*10 | 15.12 | 180*12 | 33.159 |

| 40*5 | 2.976 | 70*7 | 7.398 | 100*12 | 17.898 | 180*14 | 38.383 |

| 45*3 | 2.088 | 70*8 | 8.373 | 100*14 | 20.611 | 180*16 | 43.542 |

| 45*4 | 2.736 | 75*5 | 5.818 | 100*16 | 23.257 | 180*18 | 48.634 |

| 45*5 | 3.369 | 75*6 | 6.905 | 110*7 | 11.928 | 200*14 | 42.894 |

| 45*6 | 3.985 | 75*7 | 7.976 | 110*8 | 13.532 | 200*16 | 48.68 |

| 50*3 | 2.332 | 75*8 | 9.03 | 110*10 | 16.69 | 200*18 | 54.401 |

| 50*4 | 3.059 | 75*10 | 11.089 | 110*12 | 19.782 | 200*20 | 60.056 |

| 50*5 | 3.77 | 80*5 | 6.211 | 110*14 | 22.809 | 200*24 | 71.168 |

| 50*6 | 4.456 | 80*6 | 7.376 | 125*8 | 15.504 | ||

Isimo: Lawa ma-angle bar ane-cross-section emise okwe-L, enemilenze emibili enobude obulinganayo noma obungalingani ehlangana e-engeli engama-degree angu-90. Ukuma kwawo kuwenza afanelekele ukunikeza ukwesekwa kwesakhiwo nokuqinisa ezinhlotsheni ezahlukene zokusebenza.

Amandla kanye nomthamo wokuthwala umthwalo: Amabha e-carbon angle aklanyelwe ukunikeza amandla aphezulu okudonseka, okwenza afanelekele ukusekela imithwalo esindayo nokunikeza ukuzinza kwesakhiwo ezakhiweni.

Ukuguquguquka: Zitholakala ngobukhulu obuhlukahlukene kanye nobukhulu, okuvumela ukuguquguquka ekusetshenzisweni. Zingasetshenziswa ekubumbeni, ekuqiniseni, ekusekeleni, kanye nasezinhlotsheni ezahlukahlukene zezakhiwo.

Ukumelana nokugqwala: Kuye ngokuthi i-alloy ethile kanye nokwelashwa kwendawo, imigoqo ye-carbon angle inganikeza amazinga ahlukahlukene okumelana nokugqwala. Ukwelashwa kwendawo noma ukumbozwa okufanele kungathuthukisa ukuqina kwayo ezindaweni ezigqwalayo.

Ukukwazi ukusebenza kahle kanye nokushibilika: Imigoqo ye-carbon angle ingashintshwa kalula ngomshini, inqunywe, futhi ishiselwe, okuvumela ukuguquguquka kwezinqubo zokukhiqiza nezokwakha.

Ukuthobela amazinga: Lawa ma-angle bars avame ukukhiqizwa ukuze ahlangabezane nezindinganiso zemboni nezamazwe ngamazwe, njenge-ASTM, i-AISI, i-DIN, i-EN, kanye ne-JIS, okuqinisekisa ukuthi ahlangabezana nezidingo ezithile zemishini nezilinganiso.

Izici

Amabha e-carbon angle, aziwa nangokuthi amabha e-carbon steel angle, awuhlobo lwengxenye yensimbi yesakhiwo esetshenziswa kakhulu ekwakheni, ekukhiqizeni, kanye nasezinhlelweni zezimboni. Nazi ezinye zezici ezibalulekile zamabha e-carbon angle:

Izinto: Amabha e-carbon angle enziwe ngensimbi yekhabhoni, okuyi-iron-carbon alloy equkethe iphesenti elincane lekhabhoni (ngokuvamile ngaphansi kuka-2%). Lokhu kwaziswa kunikeza amandla amahle, ukuqina, kanye nokushibilika.

Isimo: Lawa ma-angle bar ane-cross-section emise okwe-L, enemilenze emibili enobude obulinganayo noma obungalingani ehlangana e-engeli engama-degree angu-90. Ukuma kwawo kuwenza afanelekele ukunikeza ukwesekwa kwesakhiwo nokuqinisa ezinhlotsheni ezahlukene zokusebenza.

Amandla kanye nomthamo wokuthwala umthwalo: Amabha e-carbon angle aklanyelwe ukunikeza amandla aphezulu okudonseka, okwenza afanelekele ukusekela imithwalo esindayo nokunikeza ukuzinza kwesakhiwo ezakhiweni.

Ukuguquguquka: Zitholakala ngobukhulu obuhlukahlukene kanye nobukhulu, okuvumela ukuguquguquka ekusetshenzisweni. Zingasetshenziswa ekubumbeni, ekuqiniseni, ekusekeleni, kanye nasezinhlotsheni ezahlukahlukene zezakhiwo.

Ukumelana nokugqwala: Kuye ngokuthi i-alloy ethile kanye nokwelashwa kwendawo, imigoqo ye-carbon angle inganikeza amazinga ahlukahlukene okumelana nokugqwala. Ukwelashwa kwendawo noma ukumbozwa okufanele kungathuthukisa ukuqina kwayo ezindaweni ezigqwalayo.

Ukukwazi ukusebenza kahle kanye nokushibilika: Imigoqo ye-carbon angle ingashintshwa kalula ngomshini, inqunywe, futhi ishiselwe, okuvumela ukuguquguquka kwezinqubo zokukhiqiza nezokwakha.

Ukuthobela amazinga: Lawa ma-angle bars avame ukukhiqizwa ukuze ahlangabezane nezindinganiso zemboni nezamazwe ngamazwe, njenge-ASTM, i-AISI, i-DIN, i-EN, kanye ne-JIS, okuqinisekisa ukuthi ahlangabezana nezidingo ezithile zemishini nezilinganiso.

Isicelo

Ama-angle bars ensimbi ethambile (MS), aziwa nangokuthi i-angle iron yensimbi ethambile, avame ukusetshenziswa ezinhlotsheni ezahlukene ngenxa yokuguquguquka kwawo kanye nezakhiwo zawo. Nazi ezinye zezindlela ezivamile zokusebenzisa ama-angle bars e-MS:

Ukwakhiwa: Amabha e-angle e-MS asetshenziswa kabanzi ekwakheni uzimele, ukusekela, kanye nezinhlelo zokusebenza zokusekela. Avame ukusetshenziswa ukudala uhlaka lwezakhiwo, amabhuloho, kanye namaphrojekthi engqalasizinda.

Ukukhiqiza: Lawa ma-angle bars asetshenziswa ekwakhiweni kwezingxenye zesakhiwo zemishini, imishini, kanye nezakhiwo zezimboni. Anikeza ukwesekwa okubalulekile kanye nokuqinisa emkhakheni wokukhiqiza.

Umklamo wezakhiwo kanye nowangaphakathi: Emaphrojekthini okuklama izakhiwo nangaphakathi, imigoqo ye-angle yensimbi ethambile isetshenziselwa ukudala izakhiwo zohlaka, izisekelo zezinto zokwakha, kanye nezinto zokuhlobisa. Zingasetshenziswa ngezinjongo zobuhle kanye nokusekela isakhiwo okusebenzayo.

Amashalofu nama-rack: Amabha e-angle e-MS avame ukusetshenziswa ekwakhiweni kwama-shelf units, ama-storage racks, kanye nezakhiwo ze-warehouse ngenxa yamandla azo kanye namakhono okuthwala imithwalo.

Ukukhiqiza ifenisha: Embonini yefenisha, imigoqo yensimbi ethambile isetshenziselwa ukwakha ozimele, izakhiwo zokusekela, kanye namabhuleki ezinhlobo ezahlukene zefenisha, okuhlanganisa amatafula, izihlalo, kanye nama-shelf.

Ukwenziwa kwezimoto nemishini: Lawa ma-angle bars asetshenziswa ekwakhiweni nasekuqinisweni kwamafreyimu ezimoto, ama-trailer, kanye nezisekelo zemishini ngenxa yamandla nokuqina kwawo.

Izicelo zezolimo: Emkhakheni wezolimo, imigoqo ye-MS angle isetshenziselwa ukwakha izakhiwo zepulazi, izisekelo zemishini, kanye nezindawo zokugcina izinto.

Amaphrojekthi e-DIY: Imigoqo yensimbi ethambile ivame ukusetshenziswa kumaphrojekthi okuzenzela (DIY), okuhlanganisa ukulungiswa kwekhaya, ukwakheka kwezinhlaka zezakhiwo ezenziwe ngokwezifiso, kanye nokudala izisekelo zezinhlelo zokusebenza ezahlukahlukene.

Ukupakisha Nokuthumela

Insimbi ye-engelangokuvamile ipakishwa ngendlela efanele ngokobukhulu bayo kanye nesisindo sayo ngesikhathi sokuthuthwa. Izindlela ezivamile zokupakisha zifaka:

Ukugoqa: Insimbi encane ye-engela ivame ukugoqwa ngensimbi noma nge-plastic tape ukuqinisekisa ukuphepha nokuzinza komkhiqizo ngesikhathi sokuthuthwa.

Ukupakishwa kwensimbi ye-Angle ekhanyisiwe: Uma kuyinsimbi ye-Angle ekhanyisiwe, izinto zokupakisha ezingangeni manzi nezingangeni manzi, njengefilimu yepulasitiki engangeni manzi noma ibhokisi elingangeni manzi, zivame ukusetshenziselwa ukuvimbela ukugqwala nokubola.

Ukupakishwa kokhuni: Insimbi e-engile enobukhulu noma isisindo esikhulu ingapakishwa ngokhuni, njengama-pallet okhuni noma amakesi okhuni, ukuze inikeze ukwesekwa nokuvikelwa okukhulu.

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, bese kuthi imali esele ibe yi-B/L. EXW, FOB, CFR, CIF.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.