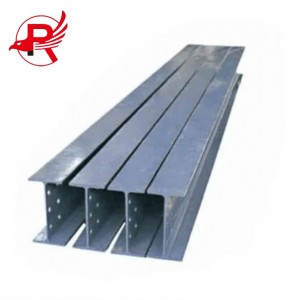

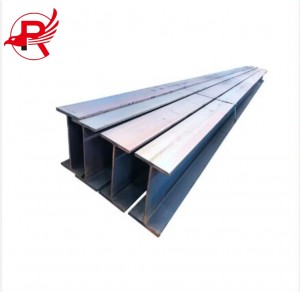

Ukwakhiwa Kwensimbi Ebunjwe Ngo-H ye-EN

Ukukhanya kwe-HInsimbi isetshenziswa kabanzi, ikakhulukazi isetshenziselwa: izakhiwo ezahlukene zokwakha zomphakathi nezezimboni; Izinhlobo ezahlukene zezitshalo zezimboni ezinde kanye nezakhiwo zesimanje eziphakeme, ikakhulukazi ezindaweni ezinomsebenzi wokuzamazama komhlaba ovame kakhulu kanye nezimo zokusebenza ezishisa kakhulu; Amabhuloho Amakhulu anomthamo omkhulu wokuthwala, ukuzinza okuhle kwezingxenye kanye nobubanzi obukhulu kuyadingeka; Imishini esindayo; Umgwaqo Omkhulu; Uhlaka lwemikhumbi; Ukusekelwa kwezimayini; Ukwelashwa kwesisekelo kanye nobunjiniyela bamadamu; Izingxenye ezahlukene zomshini.

INQUBO YOKUKHIQIZWA KOMKHIQIZO

I-flange yeUmsebe ongu-Hihambisana noma icishe ifane ngaphakathi nangaphandle, kanti ukuphela kwe-flange ku-engela engakwesokudla, ngakho-ke ibizwa ngokuthi i-parallel flange I-steel. Ubukhulu bewebhu yensimbi enomumo we-H buncane kunobe-I-beams evamile enokuphakama okufanayo kwewebhu, kanti ububanzi be-flange bukhulu kunobe-I-beams evamile enokuphakama okufanayo kwewebhu, ngakho-ke ibizwa nangokuthi i-wide-rim I-beams. Kunqunywa ngesimo, i-section modulus, umzuzu we-inertia kanye namandla ahambisanayo e-H-beam ngokusobala kungcono kunobe-I-beam evamile enesisindo esisodwa esifanayo. Isetshenziswa ezidingweni ezahlukene zesakhiwo sensimbi, kungakhathaliseki ukuthi ingaphansi kwe-torque egobile, umthwalo wokucindezela, umthwalo ongavamile ubonisa ukusebenza kwayo okuphezulu, ingathuthukisa kakhulu amandla okuthwala kune-I-steel evamile, isindisa insimbi ngo-10% ~ 40%. Insimbi enomumo we-H ine-flange ebanzi, iwebhu encane, imininingwane eminingi, kanye nokusetshenziswa okuguquguqukayo, okungasindisa u-15% kuya ku-20% wensimbi ezakhiweni ezahlukene ze-truss. Ngenxa yokuthi i-flange yayo ihambisana ngaphakathi nangaphandle, futhi ukuphela komphetho ku-engela efanele, kulula ukuyihlanganisa nokuyihlanganisa ibe izingxenye ezahlukene, okungonga cishe u-25% womsebenzi wokushisela kanye ne-riveting, futhi kungasheshisa kakhulu isivinini sokwakha sephrojekthi futhi kufinyeze isikhathi sokwakha.

USAYIZI WOMKHIQIZO

| Ukuqokwa | I-Unt Isisindo kg/m) | Isigaba Esijwayelekile ukumiswa mm | Isigaba Ama (cm² | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE28 | AA | 61.3 | 264.0 | 280.0 | 7.0 | 10.0 | 24.0 | 78.02 |

| A | 76.4 | 270.0 | 280.0 | 80 | 13.0 | 24.0 | 97.26 | |

| B | 103 | 280.0 | 280.0 | 10.5 | 18.0 | 24.0 | 131.4 | |

| M | 189 | 310.0 | 288.0 | 18.5 | 33.0 | 24.0 | 240.2 | |

| HE300 | AA | 69.8 | 283.0 | 300.0 | 7.5 | 10.5 | 27.0 | 88.91 |

| A | 88.3 | 200.0 | 300.0 | 85 | 14.0 | 27.0 | 112.5 | |

| B | 117 | 300.0 | 300.0 | 11.0 | 19.0 | 27.0 | 149.1 | |

| M | 238 | 340.0 | 310.0 | 21.0 | 39.0 | 27.0 | 303.1 | |

| HE320 | AA | 74.3 | 301.0 | 300.0 | 80 | 11.0 | 27.0 | 94.58 |

| A | 97.7 | 310.0 | 300.0 | 9.0 | 15.5 | 27.0 | 124.4 | |

| B | 127 | 320.0 | 300.0 | 11.5 | 20.5 | 27.0 | 161.3 | |

| M | 245 | 359.0 | 309.0 | 21.0 | 40.0 | 27.0 | 312.0 | |

| HE340 | AA | 78.9 | 320.0 | 300.0 | 85 | 11.5 | 27.0 | 100.5 |

| A | 105 | 330.0 | 300.0 | 9.5 | 16.5 | 27.0 | 133.5 | |

| B | 134 | 340.0 | 300.0 | 12.0 | 21.5 | 27.0 | 170.9 | |

| M | 248 | 377.0 | 309.0 | 21.0 | 40.0 | 27.0 | 315.8 | |

| HE360 | AA | 83.7 | 339.0 | 300.0 | 9.0 | t2.0 | 27.0 | 106.6 |

| A | 112 | 350.0 | 300.0 | 10.0 | 17.5 | 27.0 | 142.8 | |

| B | 142 | 360.0 | 300.0 | 12.5 | 22.5 | 27.0 | 180.6 | |

| M | 250 | 395.0 | 308.0 | 21.0 | 40.0 | 27.0 | 318.8 | |

| HE400 | AA | 92.4 | 3780 | 300.0 | 9.5 | 13.0 | 27.0 | 117.7 |

| A | 125 | 390.0 | 300.0 | 11.0 | 19.0 | 27.0 | 159.0 | |

| B | 155 | 400.0 | 300.0 | 13.5 | 24.0 | 27.0 | 197.8 | |

| M | 256 | 4320 | 307.0 | 21.0 | 40.0 | 27.0 | 325.8 | |

| HE450 | AA | 99.8 | 425.0 | 300.0 | 10.0 | 13.5 | 27.0 | 127.1 |

| A | 140 | 440.0 | 300.0 | 11.5 | 21.0 | 27.0 | 178.0 | |

| B | 171 | 450.0 | 300.0 | 14.0 | 26.0 | 27.0 | 218.0 | |

| M | 263 | 4780 | 307.0 | 21.0 | 40.0 | 27.0 | 335.4 | |

| Ukuqokwa | Iyunithi Isisindo kg/m) | Isigaba Esijwayelekile Ukushintshashintsha (mm) | Isigaba Indawo (cm²) | |||||

| W | H | B | 1 | 2 | r | A | ||

| HE50 | AA | 107 | 472.0 | 300.0 | 10.5 | 14.0 | 27.0 | 136.9 |

| A | 155 | 490.0 | 300.0 | t2.0 | 23.0 | 27.0 | 197.5 | |

| B | 187 | 500.0 | 300.0 | 14.5 | 28.0 | 27.0 | 238.6 | |

| M | 270 | 524.0 | 306.0 | 21.0 | 40.0 | 27.0 | 344.3 | |

| HE550 | AA | t20 | 522.0 | 300.0 | 11.5 | 15.0 | 27.0 | 152.8 |

| A | 166 | 540.0 | 300.0 | t2.5 | 24.0 | 27.0 | 211.8 | |

| B | 199 | 550.0 | 300.0 | 15.0 | 29.0 | 27.0 | 254.1 | |

| M | 278 | 572.0 | 306.0 | 21.0 | 40.0 | 27.0 | 354.4 | |

| HE60 | AA | t29 | 571.0 | 300.0 | t2.0 | 15.5 | 27.0 | 164.1 |

| A | 178 | 500.0 | 300.0 | 13.0 | 25.0 | 27.0 | 226.5 | |

| B | 212 | 600.0 | 300.0 | 15.5 | 30.0 | 27.0 | 270.0 | |

| M | 286 | 620.0 | 305.0 | 21.0 | 40.0 | 27.0 | 363.7 | |

| HE650 | AA | 138 | 620.0 | 300.0 | t2.5 | 16.0 | 27.0 | 175.8 |

| A | 190 | 640.0 | 300.0 | t3.5 | 26.0 | 27.0 | 241.6 | |

| B | 225 | 660.0 | 300.0 | 16.0 | 31.0 | 27.0 | 286.3 | |

| M | 293 | 668.0 | 305.0 | 21.0 | 40.0 | 27.0 | 373.7 | |

| HE700 | AA | 150 | 670.0 | 300.0 | 13.0 | 17.0 | 27.0 | 190.9 |

| A | 204 | 600.0 | 300.0 | 14.5 | 27.0 | 27.0 | 260.5 | |

| B | 241 | 700.0 | 300.0 | 17.0 | 32.0 | 27.0 | 306.4 | |

| M | 301 | 716.0 | 304.0 | 21.0 | 40.0 | 27.0 | 383.0 | |

| HE800 | AA | 172 | 770.0 | 300.0 | 14.0 | 18.0 | 30.0 | 218.5 |

| A | 224 | 790.0 | 300.0 | 15.0 | 28.0 | 30.0 | 285.8 | |

| B | 262 | 800.0 | 300.0 | 17.5 | 33.0 | 30.0 | 334.2 | |

| M | 317 | 814.0 | 303.0 | 21.0 | 40.0 | 30.0 | 404.3 | |

| HE800 | AA | 198 | 870.0 | 300.0 | 15.0 | 20.0 | 30.0 | 252.2 |

| A | 252 | 800.0 | 300.0 | 16.0 | 30.0 | 30.0 | 320.5 | |

| B | 291 | 900.0 | 300.0 | 18.5 | 35.0 | 30.0 | 371.3 | |

| M | 333 | 910.0 | 302.0 | 21.0 | 40.0 | 30.0 | 423.6 | |

| I-HEB1000 | AA | 222 | 970.0 | 300.0 | 16.0 | 21.0 | 30.0 | 282.2 |

| A | 272 | 0.0 | 300.0 | 16.5 | 31.0 | 30.0 | 346.8 | |

| B | 314 | 1000.0 | 300.0 | 19.0 | 36.0 | 30.0 | 400.0 | |

| M | 349 | 1008 | 302.0 | 21.0 | 40.0 | 30.0 | 444.2 | |

EI-NHInsimbi Ebunjiwe

Ibanga: EN10034:1997 EN10163-3:2004

Imininingwane: I-HEA HEB ne-HEM

Okujwayelekile: EN

IZICI

Kunezinhlobo eziningi zemikhiqizo ezichazwe ngezansi.Ukukhanya kwe-H, futhi izindlela zokuhlela zimi kanje.(1) Ngokusho kobubanzi be-flange yomkhiqizo, ihlukaniswe nge-flange ebanzi, i-flange ephakathi kanye ne-flange encane ye-H-beam. Ububanzi be-flange B be-flange ebanzi kanye ne-flange ephakathi ye-H-beam bukhulu noma bulingana nokuphakama kwewebhu H. Ububanzi be-flange B bensimbi encane ye-flange enomumo we-H bulingana nengxenye yokuphakama kwe-H yepuleti lewebhu.(2) Ngokusho kokusetshenziswa komkhiqizo, ihlukaniswe nge-beam yensimbi yohlobo lwe-H, ikholomu yensimbi yohlobo lwe-H, inqwaba yensimbi yohlobo lwe-H kanye ne-beam yensimbi yohlobo lwe-H ene-flange ejiyile kakhulu. Ngezinye izikhathi insimbi yesiteshi somlenze ohambisanayo kanye nensimbi ye-T-beam ehambisanayo nazo zifakiwe kububanzi be-H-beams. Ngokuvamile, insimbi ye-flange encane ye-H-beam isetshenziswa njenge-beam kanti insimbi ye-H-beam ebanzi isetshenziswa njengekholomu. Ngakho-ke, yaziwa nangokuthi insimbi ye-H-beam kanye nensimbi ye-H-beam yekholomu. (3) Ngokusho kwendlela yokukhiqiza, ihlukaniswe ngensimbi ye-H-beam ehlanganisiwe kanye nensimbi ye-H-beam egoqiwe. (4) Ngokwezincazelo zosayizi, ihlukaniswe ngensimbi enkulu, ephakathi nendawo kanye nencane enomumo we-H. Ngokuvamile, imikhiqizo enobude bewebhu obungu-H ngaphezu kuka-700mm ibizwa ngokuthi inkulu, engu-300 ~ 700mm ibizwa ngokuthi iphakathi nendawo, kanti engaphansi kuka-300mm ibizwa ngokuthi incane. Ekupheleni kuka-1990, ubude bewebhu obukhulu kunabo bonke emhlabeni obungu-1200mm, ububanzi obuhlanganisiwe obungu-530mm.

UKUHLOLWA KOMKHIQIZO

Izidingo zokuhlolwa kwensimbi enomumo we-H zifaka phakathi izici ezilandelayo:

Ikhwalithi yokubukeka: Ikhwalithi yokubukeka kwensimbi enomumo we-H kufanele ihambisane nezindinganiso ezifanele kanye nezidingo zokuhleleka. Ubuso kufanele bube bushelelezi futhi bube yisicaba, bungabi namabala asobala, imihuzuko, ukugqwala kanye nezinye izinkinga.

Ubukhulu bejometri: Ubude, ububanzi, ukuphakama, ubukhulu bewebhu, ubukhulu be-flange kanye nezinye izilinganiso zensimbi enomumo we-H kufanele zihambisane nezindinganiso ezifanele kanye nezidingo zoku-oda.

Ukugoba: Ukugoba kwensimbi enomumo we-H kufanele kuhambisane nezindinganiso ezifanele kanye nezidingo zokuhleleka. Kungatholakala ngokulinganisa ukuthi izindiza kuzo zombili izinhlangothi zensimbi enomumo we-H ziyafana noma kusetshenziswa imitha yokugoba.

Ukusonta: Ukusonta kwensimbi enobunjwa obungu-H kufanele kuhambisane nezindinganiso ezifanele kanye nezidingo zokuhleleka. Kungatholakala ngokulinganisa ukuthi uhlangothi lwensimbi enobunjwa obungu-H luqondile noma lune-twist meter.

Ukuphambuka kwesisindo: Isisindo sensimbi enomumo we-H kufanele sihambisane nezindinganiso ezifanele kanye nezidingo zokuhleleka. Ukuphambuka kwesisindo kungatholakala ngokukala.

Ukwakheka kwamakhemikhali: Uma insimbi enobunjwa obungu-H idinga ukushintshwa noma ukucutshungulwa ngenye indlela, ukwakheka kwayo kwamakhemikhali kufanele kuhambisane nezindinganiso ezifanele kanye nezidingo zoku-oda.

Izakhiwo zemishini: Izakhiwo zemishini zensimbi enomumo we-H kufanele zihambisane nezindinganiso ezifanele kanye nezidingo zoku-oda, okuhlanganisa amandla okunamathela, iphuzu lokukhiqiza, ukunwebeka nezinye izinkomba.

Ukuhlolwa Okungonakalisi: Uma insimbi enobunjwa obungu-H idinga ukuhlolwa okungangonakalisi, kufanele ihlolwe ngokuhambisana nezindinganiso ezifanele kanye nezidingo zoku-oda ukuqinisekisa ukuthi ikhwalithi yayo yangaphakathi ilungile.

Ukupakishwa nokumakwa: Ukupakishwa nokumakwa kwensimbi enomumo we-H kufanele kuhambisane nezindinganiso ezifanele kanye nezimfuneko zoku-oda ukuze kube lula ukuthuthwa nokugcinwa.

Ngamafuphi, izidingo ezingenhla kufanele zicatshangelwe ngokugcwele lapho kuhlolwa insimbi enomumo we-H ukuqinisekisa ukuthi ikhwalithi yayo ihlangabezana nezindinganiso ezifanele kanye nezidingo zoku-oda, kanye nokuhlinzeka abasebenzisi ngemikhiqizo yensimbi enomumo we-H engcono kakhulu.

Isicelo

OkuvamileUkukhanya kwe-Hizinto zensimbi zifaka phakathi i-Q235B, i-SM490, i-SS400, i-Q345 kanye ne-Q345B. Ukwakheka kwamakhemikhali kanye nezakhiwo zemishini zalezi zinto kuhlukile, ngakho-ke lapho ukhetha ukusebenzisa i-H-beam, kubalulekile ukukhetha izinto ezifanele ngokwesimo esithile.

UKUPHAKISHA NOKUTHUMELA

Ukupakisha nokuvikela:

Ukupakishwa kudlala indima ebalulekile ekuvikeleni ikhwalithi ye-ASTM A36Umsebe ongu-Hinsimbi ngesikhathi sokuthuthwa nokugcinwa kwayo. Izinto kufanele ziboshwe ngokuqinile, kusetshenziswa izintambo noma amabhande aqinile ukuvimbela ukunyakaza kanye nomonakalo ongaba khona. Ngaphezu kwalokho, kufanele kuthathwe izinyathelo zokuvikela insimbi ekuchayekeni emswakama, othulini, nakwezinye izici zemvelo. Ukugoqa izinqwaba ngezinto ezingamelani nesimo sezulu, njengepulasitiki noma indwangu engangeni manzi, kusiza ekuvikeleni ekugqwaleni nasekugqwaleni.

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, bese kuthi imali esele ibe yi-B/L. EXW, FOB, CFR, CIF.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.