Isakhiwo Sensimbi se-ASTM A36 Isakhiwo Sezentengiselwano Isakhiwo Sensimbi

ISICELO

Isakhiwo Sensimbi: Izakhiwo zensimbizisekelwa yinsimbi enamandla amakhulu, okuletha izinzuzo ezinkulu zokuba zingavimbeli ukuzamazama komhlaba, zingavimbeli umoya, ziyashesha ekwakheni futhi ziguquguquka esikhaleni.

Indlu Yesakhiwo Sensimbi:Uhlaka lwensimbiIzindlu zisebenzisa indlela efanayo yokwakha njengohlaka lwezinkuni olulula olusiza ekunciphiseni ukusetshenziswa kwamandla kanye nomthelela emvelweni, futhi zihlinzeka ngokuvikela ukushisa ngesikhathi esifushane kakhulu sokutshalwa kwezimali.

Indlu yokugcina impahla yesakhiwo sensimbi: Indlu yokugcina impahla yesakhiwo sensimbi enobubanzi obukhulu, ukusetshenziswa kwesikhala esikhulu, ukufakwa okusheshayo, okulula ukuyiklama.

Ifektri Yesakhiwo SensimbiIsakhiwo: Izakhiwo zezimboni zohlaka lwensimbi ziqinile, futhi zakhiwe ngezindawo ezivulekile ezibanzi, ngakho-ke zifanelekile ekukhiqizweni nasekusetshenzisweni kwempahla yokugcina impahla. Uma ufaka imihlobiso, amabhuleki e-unistrut noma olunye uhlelo phezu kophahla lwensimbi, udinga ukucabangela ikhono lophahla ukuze ugweme ukuguguleka.

IMINININGWANE YOMKHIQIZO

Imikhiqizo yesakhiwo sensimbi eyinhloko yokwakha ifektri

1. Isakhiwo esiyinhloko esithwala umthwalo (esivumelana nezidingo zokuzamazama komhlaba zasezindaweni ezishisayo)

| Uhlobo Lomkhiqizo | Ibanga Lokucaciswa | Umsebenzi Oyinhloko | Amaphuzu Okuzivumelanisa Nezimo eMelika Ephakathi |

| Ugongolo Lohlaka Lwesango | W12×30 ~ W16×45 (ASTM A572 Gr.50) | Ugongolo oluyinhloko lokuthwala umthwalo ophahleni/odongeni | I-Heismic node eyenzelwe ukuzamazama okuphezulu (ukuxhumeka okunamabholidi ukugwema ukushintshwa okuqhekeka), ingxenye elungiselelwe ukunciphisa isisindo sayo ukuze ithuthwe endaweni. |

| Ikholomu Yensimbi | I-H300×300 ~ H500×500 (ASTM A36) | Isekela imithwalo yohlaka kanye nephansi | Izixhumi zokuzamazama ezifakwe esisekelo; indawo eshisayo ekhanyisiwe (i-zinc coating ≥85μm) ukuze kube nomswakama ophezulu ukuvikela ukugqwala. |

| Umsebe we-Crane | W24×76 ~ W30×99 (ASTM A572 Gr.60) | Ukuthwala umthwalo wokusebenza kwe-crane yezimboni | Yakhelwe umthwalo omkhulu (iyahambisana nama-crane angu-5 ~ 20t), ukuma komsebe wokugcina kwakhiwa ngamapuleti okuxhuma amelana nokucheba. |

2. Imikhiqizo yesistimu yokuvala (evikela isimo sezulu + elwa nokugqwala)

Ama-purlin ophahleni: C12×20~C16×31 (ifakwe i-hot-dip galvanized), ihlukaniswe nge-1.5~2m, ifanele ukufakwa kwepuleti lensimbi elimbozwe ngombala, futhi imelana nemithwalo yesiphepho kuze kufike ezingeni le-12.

Ama-purlin odongeni: Z10×20~Z14×26 (ependwe ngopende wokulwa nokugqwala), enezimbobo zokungenisa umoya ukuze kuncishiswe umswakama ezimbonini zasezindaweni ezishisayo.

Uhlelo lokusekela: Ukusekela (Φ12~Φ16 insimbi eyindilinga egayiwe eshisayo) kanye nama-braces asekhoneni (ama-engeli ensimbi angu-L50×5) kuthuthukisa ukumelana kwesakhiwo ohlangothini ukuze kumelwane nemimoya yamandla esiphepho.

3. Ukusekela imikhiqizo esekelayo (ukulungiswa kokwakhiwa kwendawo)

- 1. Izingxenye ezifakiwe: Izingxenye ezifakiwe zepuleti lensimbi (ubukhulu obuyi-10mm kuya ku-20mm, i-Hot-dip galvanized) zifanelekela isisekelo sekhonkrithi esivame ukusetshenziswa eMelika Ephakathi;

2. Ama-Connectors: Ama-bolt anamandla aphezulu (ibanga 8.8, i-hot dip galvanized), lokhu kuqeda isidingo sokushisela endaweni futhi kunciphisa isikhathi sokwakha;

3. Upende ovimbela umlilo osekelwe emanzini (ukumelana nomlilo ≥1.5h) kanye nopende ovimbela ukugqwala we-Acrylic (ukuvikelwa kwe-UV, isikhathi sokuphila ≥iminyaka eyi-10) ongahlangabezana nezidingo zokuvikela imvelo zendawo.

UKUCUTSHUNGULWA KWESAKHIWO SENTSIMBI

| Indlela Yokucubungula | Imishini Yokucubungula | Ukucubungula |

| Ukusika | Imishini yokusika i-plasma/ilangabi ye-CNC, imishini yokugunda izinwele | Ukusikwa kwe-plasma/ilangabi le-CNC (kwamapuleti/izingxenye zensimbi), ukugunda (kwamapuleti ensimbi amancane), ngokunemba okulawulwayo kobukhulu |

| Ukwakha | Umshini wokugoba obandayo, ibhuleki lokucindezela, umshini wokugoqa | Ukugoba okubandayo (kwama-purlin e-C/Z), ukugoba (kwama-gutter/ukusika umphetho), ukugoqa (kwama-bar okusekela ayindilinga) |

| Ukushisela | Umshini wokushisela we-arc ocwiliswe emanzini, umshini wokushisela we-arc osetshenziswa ngesandla, umshini wokushisela we-CO₂ ovikelwe ngegesi | Ukushisela kwe-arc okucwiliswe emanzini (kwamakholomu/imisebe enobunjwa obungu-H), ukushisela kwe-arc ngesandla (kwamapuleti e-gusset), ukushisela okuvikelwe ngegesi i-CO₂ (kwezingxenye ezinezindonga ezincane) |

| Ukwenza imigodi | Umshini wokubhoboza we-CNC, umshini wokubhoboza | Ukubhoboza nge-CNC (kwemigodi yamabholidi kumapuleti/izingxenye zokuxhuma), ukubhoboza (kwemigodi emincane yebhetshi), ngobubanzi bemigodi elawulwayo kanye nokubekezelelana kwezikhundla |

| Ukwelashwa | Umshini wokuqhumisa ngokudubula/wokuqhumisa ngesihlabathi, umshini wokugaya, umugqa wokugaya ngokushisa | Ukususa ukugqwala (ukuqhumisa amashothi/ukuqhumisa isihlabathi), ukugaya nge-weld (kokususa ukubhoboza), ukugaya nge-hot-dip (kwama-bolts/izisekeli) |

| Ukuhlanganiswa | Ipulatifomu yokuhlanganisa, izinto zokulinganisa | Izingxenye ezihlanganiswayo ngaphambi kokuhlanganiswa (amakholomu + imisebe + izisekelo), zihlukaniswe ngemva kokuqinisekiswa kobukhulu ukuze zithunyelwe |

UKUHLOLWA KWESAKHIWO SENTSIMBI

| 1. Ukuhlolwa kokufutha ngosawoti (ukuhlolwa kokugqwala okuyinhloko) Ihambisana ne-ASTM B117 (isifutho sikasawoti esingathathi hlangothi)/ISO 11997-1 (isifutho sikasawoti esijikelezayo), esifanele ukuchayeka emoyeni onosawoti ogwini lwaseMelika Ephakathi. | 2. Ukuhlolwa kokunamathela Ukuhlolwa kwe-cross-hatch ngokuhambisana ne-ASTM D3359 (cross-hatch/grid-grid, ukuhlola izinga lokuxebuka); ukuhlolwa kwe-pull-off ngokuhambisana ne-ASTM D4541 (ukuhlola amandla e-peel phakathi kwe-coating kanye ne-substrate yensimbi). | 3. Ukuhlolwa komswakama nokumelana nokushisa I-ASTM D2247 (40°C/95% RH) ukuvikela ekuqhekekeni nasekuqhekekeni kwengubo ngesikhathi semvula). |

| 4. Ukuhlolwa kokuguga kwe-UV I-ASTM G154 (ukulingisa ukuchayeka okukhulu kwe-UV emahlathini emvula ukuze kuvinjelwe ukufiphala nokushiswa kwengubo). | 5. Ukuhlolwa kobukhulu befilimu Ubukhulu befilimu eyomile nge-ASTM D7091 (igeyiji yobukhulu be-magnetic); ubukhulu befilimu emanzi nge-ASTM D1212 (ukuqinisekisa ukuthi ukumelana nokugqwala kwanele ukuqina kwefilimu emanzi). | 6. Ukuhlolwa kwamandla omthelela I-ASTM D2794 (ukushaya kwesando sokuphonsa, ukugwema umonakalo ngesikhathi sokuthunyelwa/ukuphathwa). |

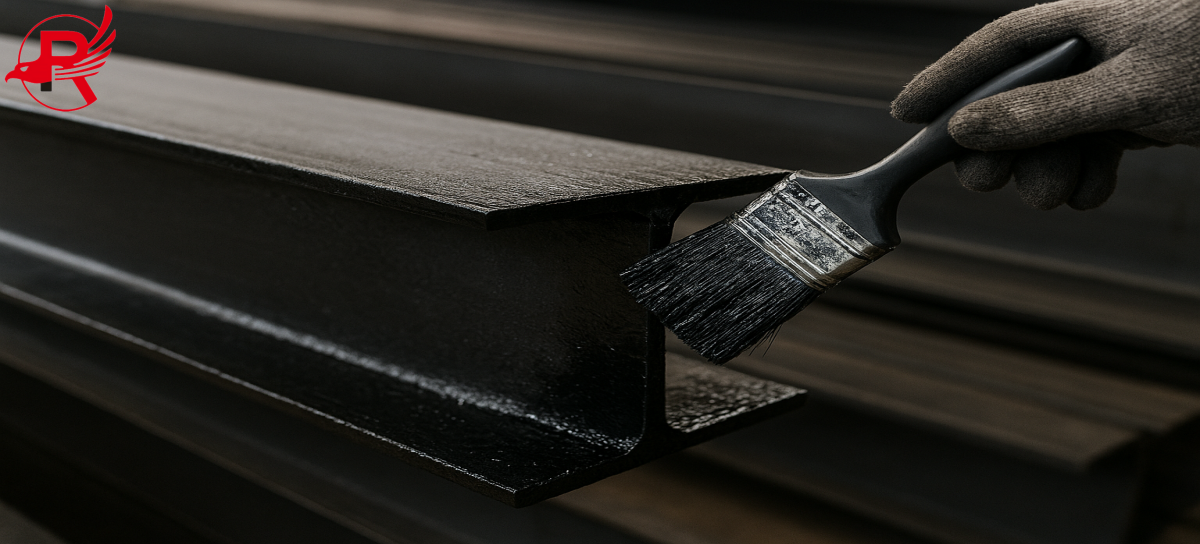

UKWELASHWA KOMHLABA

Isibonisi Sokwelashwa Komphezulu:Isembozo esicebile nge-zinc e-Epoxy, esifakwe i-galvanized (ubukhulu besendlalelo esifakwe i-hot dip galvanized ≥85μm isikhathi senkonzo singafinyelela eminyakeni eyi-15-20), esifakwe amafutha amnyama, njll.

Okunamafutha Amnyama

I-Galvanised

Ukugqoka okucebile nge-zinc e-epoxy

UKUPHAKISHA NOKUTHUMELA

Ukupakisha:

I-Steel Construction ipakishwa ngokucophelela ukuze ivikele ukuqeda futhi iqinisekise ubuqotho besakhiwo ngesikhathi sokuphathwa nokuthunyelwa. Izingxenye zivame ukugoqwa ngezinto ezingangeni manzi njengefilimu yepulasitiki noma iphepha elingagqwali, kanti izesekeli ezincane zitholakala emabhokisini ezinkuni. Kodwa-ke, zonke izinqwaba noma izingxenye ziphawulwe ngendlela ekhethekile ukuze kungabikho ukudideka lapho uzithulula ngokuphephile futhi uzifake kahle endaweni.

Ezokuthutha:

Iuhlaka lwensimbiingathunyelwa ngesitsha noma ngomkhumbi omkhulu kuye ngobukhulu nendawo oya kuyo. Amaphakheji amakhulu, aqinile ezintambo aboshwe ngentambo yensimbi kanye nokhuni kunoma yiluphi uhlangothi ukuze kuvinjelwe ukunyakaza nokulimala ngesikhathi sokuthutha. Zonke izinsizakalo zokuthutha zenziwa ngaphansi kwezindinganiso zokuhamba zamazwe ngamazwe eziqinisekisa ukulethwa ngesikhathi, ukufika okuphephile, ukuthunyelwa okude ngisho noma ukuthunyelwa kwemikhumbi edlula emngceleni.

IZINZUZO ZETHU

1. Amagatsha Aphesheya Kwezwe kanye Nokusekelwa KwaseSpain

Amaqembu akhuluma iSpanishi emahhovisi ethu aphesheya kwezilwandle asiza amaklayenti aseLatin America naseYurophu ngokuxhumana, amasiko, imibhalo, kanye nezinhlelo zokuthutha ukuqinisekisa ukulethwa okubushelelezi nokuphumelelayo.

2. Isitoko Esilungele Ukulethwa Okusheshayo

Sigcina uhlu olwanele lwemisebe ye-H, imisebe ye-I, kanye nezingxenye zesakhiwo, okuvumela isikhathi esifushane sokuhola kanye nokunikezwa okusheshayo kwamaphrojekthi aphuthumayo.

3. Ukupakisha Okuchwepheshile

Yonke imikhiqizo isebenzisa ukupakishwa okufanelekela ulwandle—ukubopha ngohlaka lwensimbi, ukugoqa okungangeni manzi, kanye nokuvikelwa konqenqema—ukuqinisekisa ukuthuthwa okuphephile kanye nokufika okungenamonakalo.

4. Ukuthunyelwa Nokulethwa Okusebenzayo

Ngozakwethu bokuthumela abathembekile kanye nemibandela eguquguqukayo (i-FOB, i-CIF, i-DDP), sinikeza ukulethwa ngesikhathi kanye nokulandelela okuphumelelayo ngomkhumbi noma ngesitimela.

Imibuzo Evame Ukubuzwa

Ngokuphathelene nekhwalithi yezinto ezibonakalayo

U: Yiziphi izindinganiso ezifinyelelwa yizakhiwo zakho zensimbi?

A: Isakhiwo sethu sensimbi sihambisana nezindinganiso zaseMelika ezifana ne-ASTM A36, i-ASTM A572 njll. Isibonelo, i-ASTM A36 iyisakhiwo sekhabhoni esijwayelekile, i-A588 iyisakhiwo esimelana nesimo sezulu esibi kakhulu ukuze sisetshenziswe endaweni enomoya oshisayo.

U: Ungaqinisekisa kanjani ikhwalithi yezinto zakho zensimbi?

A: Sithola izinto zokusetshenziswa zensimbi ezivela ezimbonini zensimbi zasekhaya noma zaphesheya kwezilwandle ezithembekile ezinesistimu yokulawula ikhwalithi eqinile. Yonke imikhiqizo ihlolwa kakhulu lapho ifika, phakathi kwazo kukhona ukuhlaziywa kokwakheka kwamakhemikhali, ukuhlolwa kwezakhiwo zemishini kanye nokuhlolwa okungabhubhisi okuhlanganisa i-Ultrasonic Testing (UT) kanye ne-Magnetic Particle Testing (MPT) ukuqinisekisa ukuthi ikhwalithi ihambisana nezindinganiso ezihlobene.

Ikheli

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

I-imeyili

Ucingo

+86 13652091506