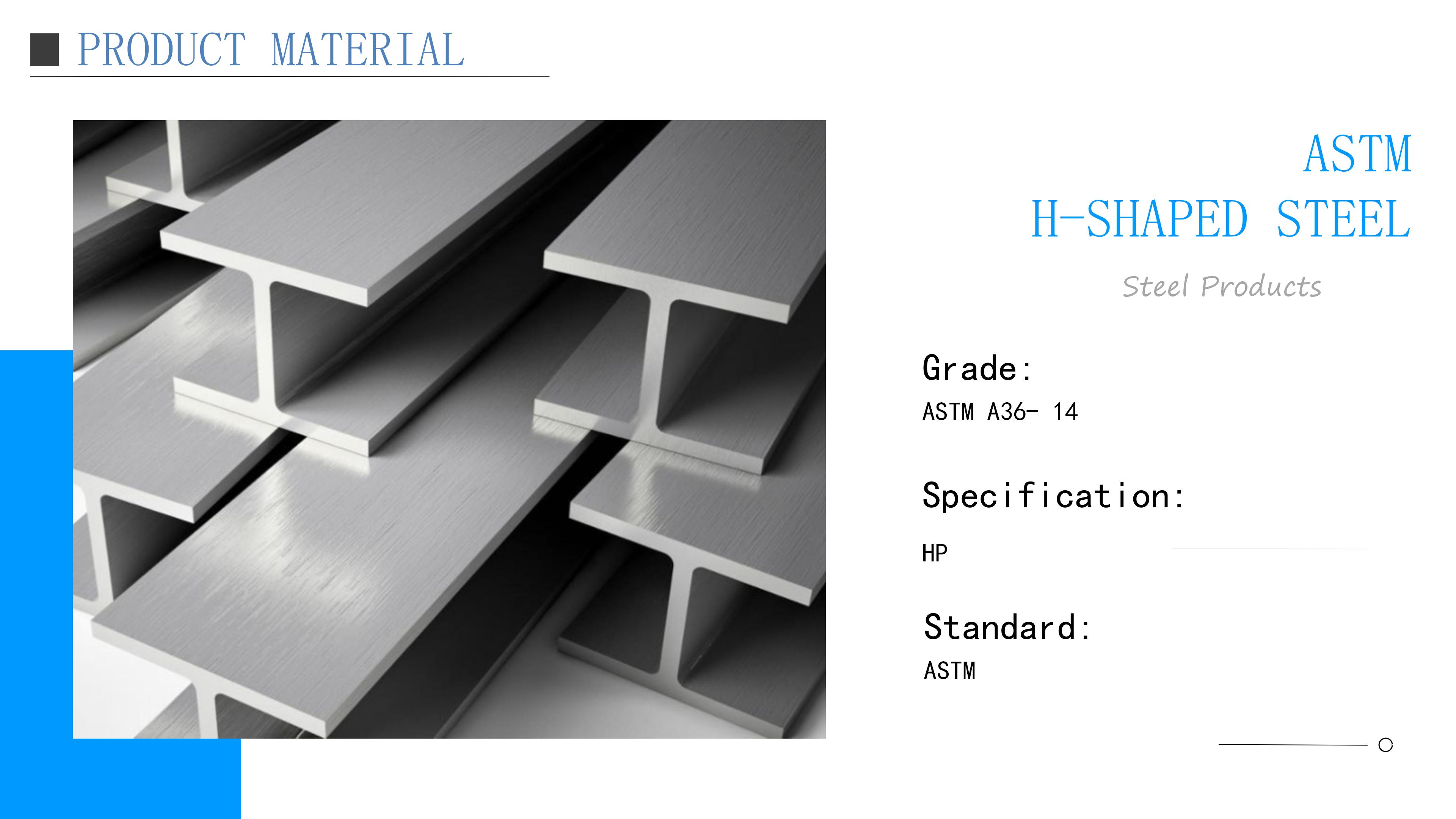

Insimbi Ebunjwe Ngo-H ye-ASTM Ugongolo lwe-Carbon Ugongolo lwe-Channel Steel

Imininingwane Yomkhiqizo

Imininingwane ethile yeInsimbi enomumo ongu-Hngokuvamile kufaka phakathi ubukhulu obufana nokuphakama, ububanzi be-flange, ukujiya kwewebhu, kanye nobukhulu be-flange. Le mininingwane iyahlukahluka ngokusekelwe kumklamo othize kanye nokusetshenziswa okuhlosiwe kwe-H-beam. I-H-beams iyatholakala ngobukhulu obuhlukahlukene kanye nokucaciswa, okuvumela ukuguquguquka ekuhlangabezaneni nezidingo zokwakha ezahlukahlukene.

Ngaphezu kokusetshenziswa kwazo ezakhiweni nasemabhulohweni,Imisebe ye-Hzisetshenziswa nasezinhlelweni ezahlukene zezimboni, njengokusekela imishini esindayo nemishini. Ukuguquguquka kanye namandla ensimbi enomumo we-H kwenza kube yinto ebalulekile ekudaleni izakhiwo ezizinzile neziqinile kanye nezinhlaka kokubili ezindaweni zokwakha kanye nezimboni.

| IZINHLOBO ZOKUCACISAUMGQA O-H | |

| 1. Usayizi | 1) Ubukhulus:5-34mmnoma ngokwezifiso |

| 2) Ubude:6-12m | |

| 3) Ubukhulu bewebhu:6mm-16mm | |

| 2. Okujwayelekile: | JIS ASTM DIN EN GB |

| 3. Izinto | Q195 Q235 Q345 A36 S235JR S335JR |

| 4. Indawo yefektri yethu | I-Tianjin, China |

| 5. Ukusetshenziswa: | 1) isakhiwo sezimboni eziphakeme |

| 2) Izakhiwo Ezindaweni Ezivame Ukuzamazama Komhlaba | |

| 3) amabhuloho amakhulu anezinsika ezinde | |

| 6. Ukugqoka: | 1) Ubekiwe 2) Okupendwe Ngomnyama (ukumbozwa kwevarnish) 3) i-galvanized |

| 7. Inqubo: | hot rolled |

| 8. Uhlobo: | Inqwaba yeshidi lohlobo lwe-H |

| 9. Isimo Sesigaba: | H |

| 10. Ukuhlolwa: | Ukuhlolwa noma ukuhlolwa kweklayenti yiqembu lesithathu. |

| 11. Ukulethwa: | Isitsha, Isitsha Esibanzi. |

| 12. Mayelana Nekhwalithi Yethu: | 1) Akukho monakalo, akukho ukugoba 2) Mahhala ukugcotshwa ngamafutha nokumaka 3) Zonke izimpahla zingahlolwa ngokuhlolwa komuntu wesithathu ngaphambi kokuthunyelwa |

| UDivis ibn (ukujula x idth | Iyunithi Isisindo kg/m) | I-Sandard Sectional Ubukhulu (mm) | Okwesigaba Indawo cm² | ||||

| W | H | B | 1 | 2 | r | A | |

| I-HP8x8 | 53.5 | 203.7 | 207.1 | 11.3 | 11.3 | 10.2 | 68.16 |

| I-HP10x10 | 62.6 | 246.4 | 255.9 | 10.5 | 10.7 | t2.7 | 70.77 |

| 85.3 | 253.7 | 259.7 | 14.4 | 14.4 | 127 | 108.6 | |

| I-HP12x12 | 78.3 | 2992 | 305.9 | 11.0 | 11.0 | 15.2 | 99.77 |

| 93.4 | 303.3 | 308.0 | 13.1 | 13.1 | 15.2 | 119.0 | |

| 111 | 308.1 | 310.3 | 15.4 | 15.5 | 15.2 | 140.8 | |

| 125 | 311.9 | 312.3 | 17.4 | 17.4 | 15.2 | 158.9 | |

| HP14x14% | 108.0 | 345.7 | 370.5 | 12.8 | t2.8 | 15.2 | 137.8 |

| 132.0 | 351.3 | 373.3 | 15.6 | 15.6 | 15.2 | 168.4 | |

| 152.0 | 355.9 | 375.5 | 17.9 | 17.9 | 15.2 | 193.7 | |

| 174.0 | 360.9 | 378.1 | 20.4 | 20.4 | 15.2 | 221.5 | |

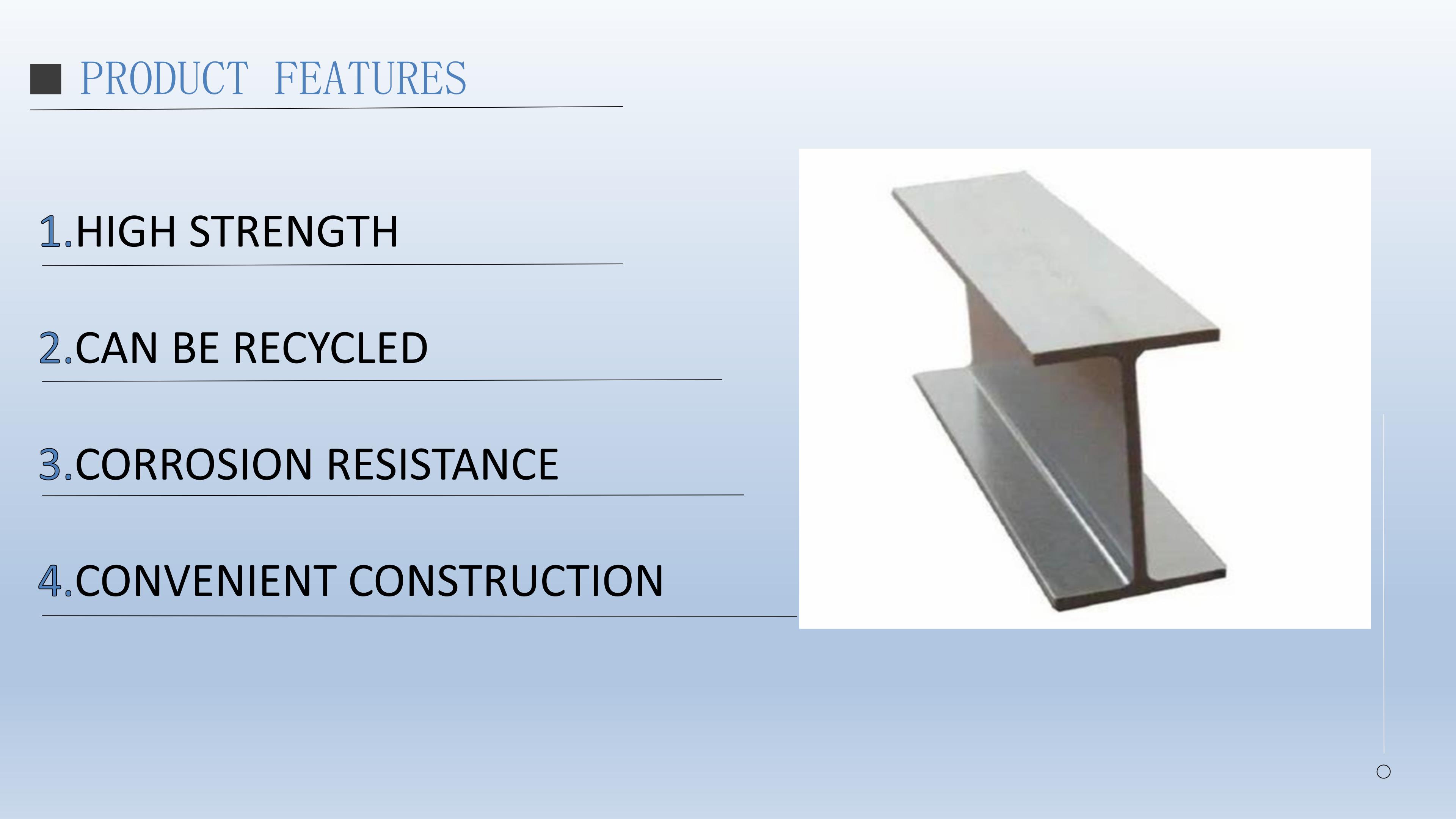

Izici

Insimbi enomumo ongu-Henkambisweni yokupakisha kanye nokuthutha, kudingeka banake izinto ezilandelayo:

Ukupakisha: Insimbi enomumo ongu-Hkudingeka zipakishwe kahle ngaphambi kokuthuthwa ukuze kuvinjelwe umonakalo womphezulu. Izinto zokupakisha ezivamile zifaka ama-pallet okhuni, amabhokisi okhuni, ukupakisha kwepulasitiki njalo njalo. Izinto zokupakisha kudingeka ziqine futhi zizinzile ngokwanele ukuqinisekisa ukuthi insimbi enobunjwa obungu-H ngeke icindezelwe noma ishaywe lapho kuthuthwa.

Ukumaka:Isisindo, usayizi, imodeli kanye nolunye ulwazi lwe-Insimbi enomumo ongu-Hkufanele kuphawulwe ngokucacile ephaketheni ukuze kube lula ukuhlonza ngesikhathi sokuthuthwa nokusetshenziswa.

Ukuphakamisa nokuphatha:Lapho uphakamisa futhi uphatha imisebe ye-H, kudingeka imishini yokuphakamisa efanele kanye nama-hook ukuqinisekisa ukusebenza okuphephile nokuzinzile.

Ezokuthutha:Khetha izindlela nezindlela ezifanele zokuthutha ukuqinisekisa ukuthi insimbi enomumo we-H ngeke ibhekane nokudlidliza okukhulu nokudlidliza ngesikhathi sokuthutha.

Isicelo

Izicelo zeImisebe Yesigaba Se-H:

Ukuguquguquka kwemishayo yesigaba se-H kuyenza ibe yinto ebalulekile emisebenzini eminingi yokwakha. Imishayo yesigaba se-H isebenza njengezinto eziyinhloko zokwakha ekwakhiweni kwamabhuloho, inikeza umgogodla wezindawo eziqinile nezihlala isikhathi eside. Amandla azo okubekezelela imithwalo esindayo nokumelana namandla aseceleni azenza zilungele izakhiwo eziphakeme, okuqinisekisa ukuzinza nokwamukela izikhala ezinkulu zaphansi. Ngaphezu kwalokho,Imisebe yesigaba se-Hthola izinhlelo zokusebenza ezindaweni zezimboni, ukusekela imishini esindayo kanye nokunikeza indawo yokugcina ephakanyisiwe eyanele.

Imisebe yesigaba se-HZisetshenziswa kabanzi embonini yokwakha imikhumbi, lapho amandla azo aphezulu okuthwala imithwalo kanye nokumelana nokugqwala kuzenza zibe zilungele ukwakha izakhiwo ezahlukene zasolwandle. Ngaphezu kwalokho, imiklamo yezakhiwo yesimanje ivame ukusebenzisa imishayo yesigaba se-H njengezinto zokuklama ezijabulisa ubuhle, okwengeza ukuthinta kwezimboni ezakhiweni zesimanje.

Ukupakisha Nokuthumela

Ukupakisha:

Beka izinqwaba zamaphepha ngokuphephile: HlelaI-H-Beamendaweni ehlelekile nezinzile, ukuqinisekisa ukuthi zibekwe kahle ukuze kuvinjelwe noma yikuphi ukungazinzile. Sebenzisa ibhande noma ukubopha ukuze uqinise inqwaba futhi uvimbele ukugudluka ngesikhathi sokuthuthwa.

Sebenzisa izinto zokuvikela zokupakisha: Songa inqwaba yamashidi ngezinto ezingangenisi umswakama, njengepulasitiki noma iphepha elingangeni manzi, ukuze uzivikele ekuchayweni amanzi, umswakama, nezinye izinto zemvelo. Lokhu kuzosiza ekuvimbeleni ukugqwala nokugqwala.

Ukuthunyelwa:

Khetha indlela yokuhamba efanele: Kuye ngobuningi kanye nesisindo sezinqwaba zamashidi, khetha indlela yokuhamba efanele, njengamaloli ayisicaba, izitsha, noma imikhumbi. Cabangela izici ezifana nebanga, isikhathi, izindleko, kanye nanoma yiziphi izidingo zomthetho zokuhamba.

Sebenzisa imishini yokuphakamisa efanele: Ukulayisha nokukhulula imithwaloIzinqwaba zensimbi ezimise okwe-U, sebenzisa imishini yokuphakamisa efanele njengamakhreyini, ama-forklift, noma ama-loader. Qinisekisa ukuthi imishini esetshenziswayo inamandla anele okuphatha isisindo sezinqwaba zamashidi ngokuphephile.

Vikela umthwalo: Vikela kahle inqwaba epakishiweizinqwaba zamashidiemotweni yokuthutha usebenzisa izintambo, izinsimbi zokubopha, noma ezinye izindlela ezifanele zokuvimbela ukugudluka, ukushelela, noma ukuwa ngesikhathi sokuhamba.

Imibuzo Evame Ukubuzwa

1. Ngingayithola kanjani ikhotheshini kuwe?

Ungasishiyela umyalezo, futhi sizophendula yonke imiyalezo ngesikhathi.

2. Ingabe uzoletha izimpahla ngesikhathi?

Yebo, sithembisa ukuhlinzeka ngemikhiqizo esezingeni eliphezulu kanye nokulethwa ngesikhathi. Ukwethembeka kuyisimiso senkampani yethu.

3. Ngingayithola yini amasampula ngaphambi koku-oda?

Yebo, kunjalo. Ngokuvamile amasampula ethu amahhala, singawakhiqiza ngamasampula akho noma ngemidwebo yobuchwepheshe.

4. Iyini imigomo yakho yokukhokha?

Isikhathi sethu sokukhokha esijwayelekile yidiphozithi engu-30%, bese kuthi imali esele ibe yi-B/L. EXW, FOB, CFR, CIF.

5. Uyakwamukela ukuhlolwa komuntu wesithathu?

Yebo siyakwamukela ngempela.

6. Siyethemba kanjani inkampani yakho?

Sisebenza ngobuchwepheshe ebhizinisini lensimbi iminyaka eminingi njengomhlinzeki wegolide, indlunkulu isesifundazweni saseTianjin, samukelekile ukuzohlola nganoma yiziphi izindlela, ngazo zonke izindlela.