Ipuleti Lensimbi Yekhabhoni Ethambile Yebanga le-ASTM A283 / Ishidi Lensimbi Egqinsiwe Eyenziwe Nge-Galvanised Engu-6mm

Imininingwane Yomkhiqizo

Ishidi elihlanganisiweKubhekisela eshidini lensimbi elimbozwe ungqimba lwe-zinc phezu komhlaba. I-Galvanizing iyindlela yokuvimbela ukugqwala engabizi futhi ephumelelayo evame ukusetshenziswa, futhi cishe ingxenye yokukhiqizwa kwe-zinc emhlabeni isetshenziswa kule nqubo.

Ngokwezindlela zokukhiqiza nokucubungula, ingahlukaniswa ngezigaba ezilandelayo:

Ishidi lensimbi elicwengekile elishisayo. Faka ipuleti lensimbi elincane ethangini le-zinc elincibilikisiwe ukuze wenze ipuleti lensimbi elincane elinesendlalelo se-zinc esinamathele ebusweni balo. Njengamanje, inqubo eqhubekayo yokwenza i-galvanizing isetshenziswa kakhulu ekukhiqizeni, okungukuthi, ipuleti lensimbi elihlanganisiwe lihlala licwiliswa ethangini lokwenza i-galvanizing nge-zinc encibilikisiwe ukuze kwenziwe ipuleti lensimbi eliqinisiwe;

Insimbi egayiwe nge-alloy. Lolu hlobo lwensimbi lukhiqizwa kusetshenziswa indlela ye-hot-dip galvanizing, kodwa ishiswa ngokushesha cishe ku-500°C ngemva kokuphuma ethangini ukuze yakhe ifilimu ye-zinc-iron alloy. Lolu hlobo lwensimbi egayiwe lubonisa ukunamathela okuhle kakhulu kopende kanye nokushibilika.

Insimbi egayiwe nge-electrogalvanized. Insimbi egayiwe ekhiqizwa kusetshenziswa indlela ye-electroplating inikeza ukusebenza okuhle kakhulu, kodwa ungqimba luncane futhi ukumelana kwalo nokugqwala kungaphansi kokwensimbi egayiwe eshisayo.

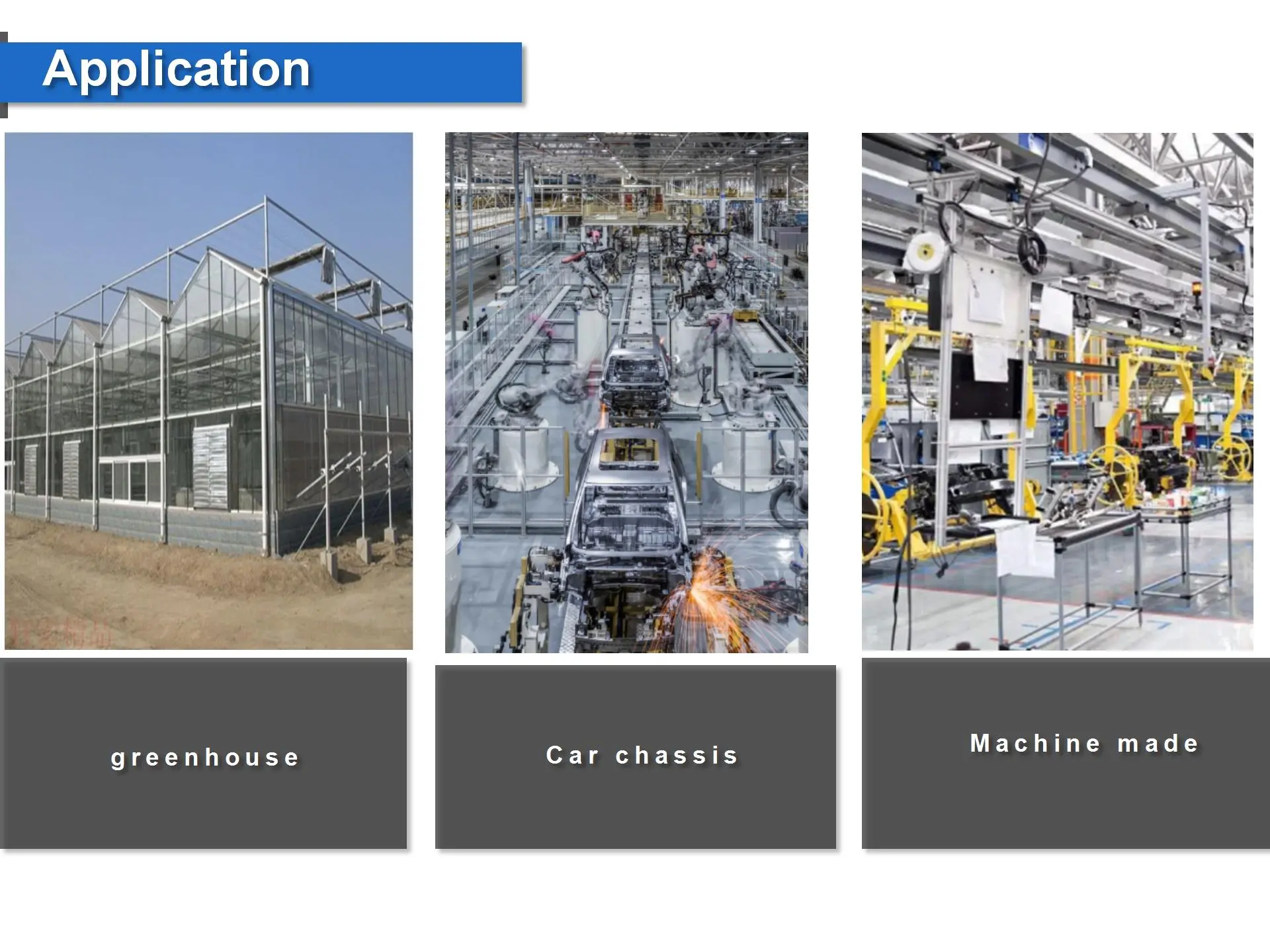

Isicelo Esiyinhloko

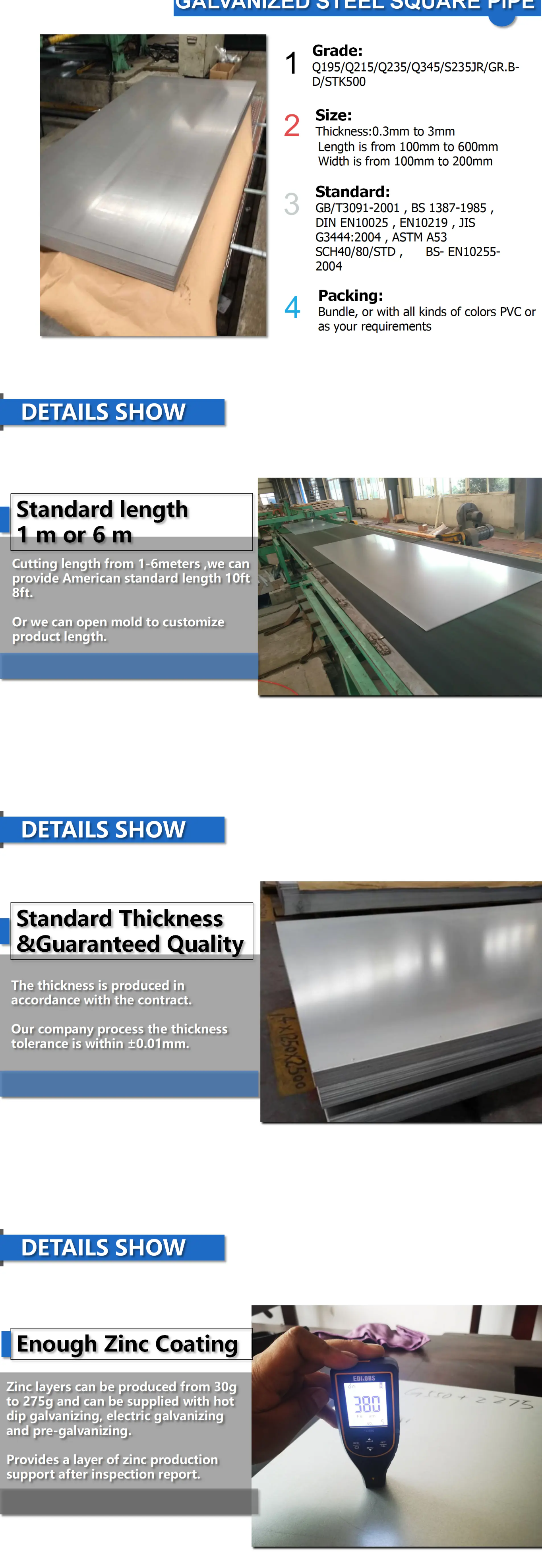

Izici

1. Ukumelana nokugqwala, ukupendwa kalula, ukwakheka kalula, kanye nokushiselwa kwamabala.

2. Isetshenziswa kabanzi, ikakhulukazi ezingxenyeni ezincane zemishini ezidinga ubuhle obuphezulu. Kodwa-ke, ibiza kakhulu kune-SECC, okwenza abakhiqizi abaningi bashintshele ku-SECC ukuze bonge izindleko.

3. Ukuhlukaniswa ngokwesendlalelo se-zinc: Usayizi wama-zinc spangles kanye nobukhulu besendlalelo se-zinc kubonisa ikhwalithi yenqubo yokugaya; uma ama-zinc amancane futhi ungqimba lwe-zinc lukhudlwana, kungcono. Abakhiqizi bangase bangeze ukwelashwa okulwa nokunyatheliswa kweminwe. Ngaphezu kwalokho, amamaki angahlukaniswa ngesendlalelo sokumboza; isibonelo, i-Z12 ikhombisa ukumbozwa okuphelele okungu-120g/mm nhlangothi zombili.

Isicelo

Amapharamitha

| Izinga Lobuchwepheshe | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Ibanga Lensimbi | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), I-SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); noma kwamakhasimende Isidingo |

| Ubukhulu | imfuneko yekhasimende |

| Ububanzi | ngokwezidingo zekhasimende |

| Uhlobo Lokumboza | Insimbi Eshisayo Ecwiliswe Ngogesi (HDGI) |

| Isimbozo seZinc | 30-275g/m2 |

| Ukwelashwa Okuphezulu | Ukudlulisa (C), Ukufaka uwoyela (O), Ukuvala i-Lacquer (L), Ukuphosphating (P), Okungaphathwanga (U) |

| Isakhiwo Somphezulu | Ukugqoka okujwayelekile kwe-spangle (NS), ukugqoka okuncishisiwe kwe-spangle (MS), okungena-spangle (FS) |

| Ikhwalithi | Kuvunywe yi-SGS, ISO |

| ID | 508mm/610mm |

| Isisindo sekhoyili | I-metric ton engu-3-20 nge-coil ngayinye |

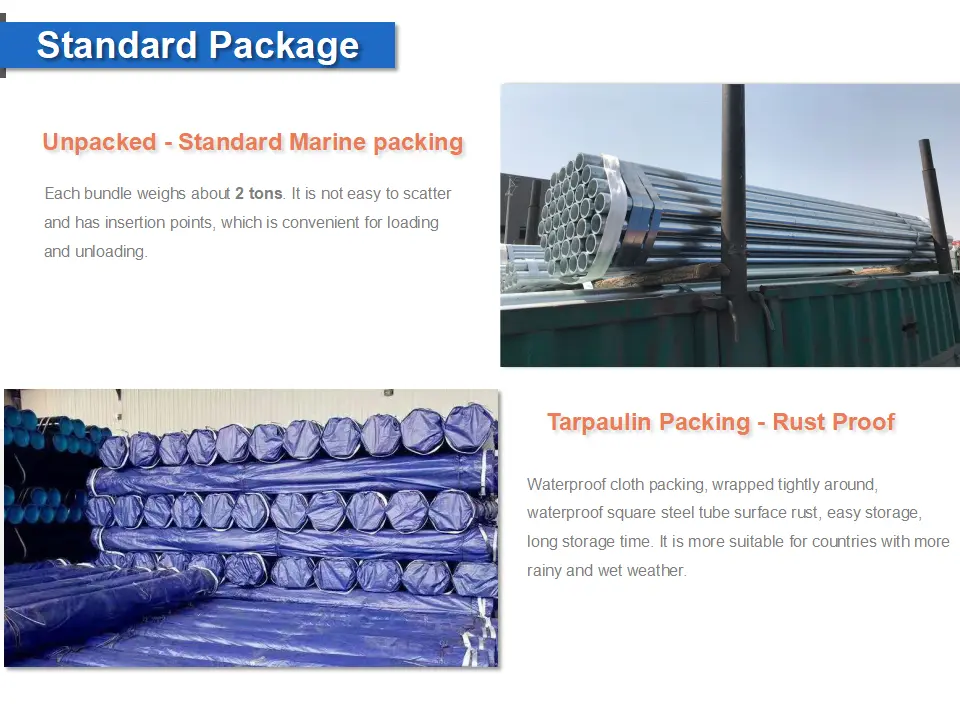

| Iphakheji | Iphepha elingangeni manzi liyiphakheji yangaphakathi, insimbi eboshwe nge-galvanized noma ishidi lensimbi elimboziwe liyiphakheji yangaphandle, ipuleti lonogada ohlangothini, bese ligoqwa ibhande lensimbi eliyisikhombisa. noma ngokwezidingo zekhasimende |

| Imakethe yokuthumela ngaphandle | IYurophu, i-Afrika, i-Asia Ephakathi, iNingizimu-mpumalanga ye-Asia, iMpumalanga Ephakathi, iNingizimu Melika, iNyakatho Melika, njll. |

Dei-livery

Imibuzo Evame Ukubuzwa

Q: Ingabe abakhiqizi be-ua?

A: Yebo, singabakhiqizi. Sinefektri yethu etholakala eTianjin City, eShayina.

Q: Ngingaba ne-oda lokuhlola amathani ambalwa kuphela?

A: Vele. Singakuthumela umthwalo ngesevisi ye-LCL. (Umthwalo wesitsha omncane)

Q: Uma isampula imahhala?

A: Isampula ayitholakali, kodwa umthengi ukhokhela imithwalo.

U: Ingabe ungumphakeli wegolide futhi wenza isiqinisekiso sokuhweba?

A: Sihlinzeka ngegolide iminyaka eyisikhombisa futhi samukela isiqinisekiso sokuhweba.